With the rapid development of drone technology, drones are increasingly applied in various industries, ranging from logistics and agriculture monitoring to industrial inspections. As the scope of drone applications expands, the complexity of their operating environments also increases. Meanwhile, managing the heat generated during flight has become one of the critical challenges in drone design. Core components like batteries, motors, processors, and sensors generate a substantial amount of heat under high load conditions. If this heat is not dissipated in time, it may cause system overheating, performance degradation, or even failure.

To address this issue, the choice of efficient thermal interface materials (TIMs) is crucial. As a leader in the thermal management field, NFION offers specialized thermal materials designed for drone thermal management, including thermal silicone pads and thermal gels. These materials excel in heat conductivity, environmental adaptability, and compressibility, significantly enhancing the stability and reliability of drone systems in practical applications.

Drone Structure and Thermal Management Needs

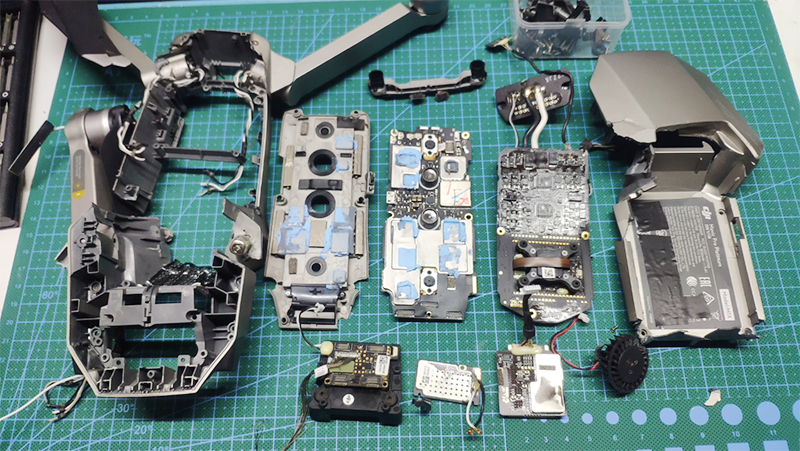

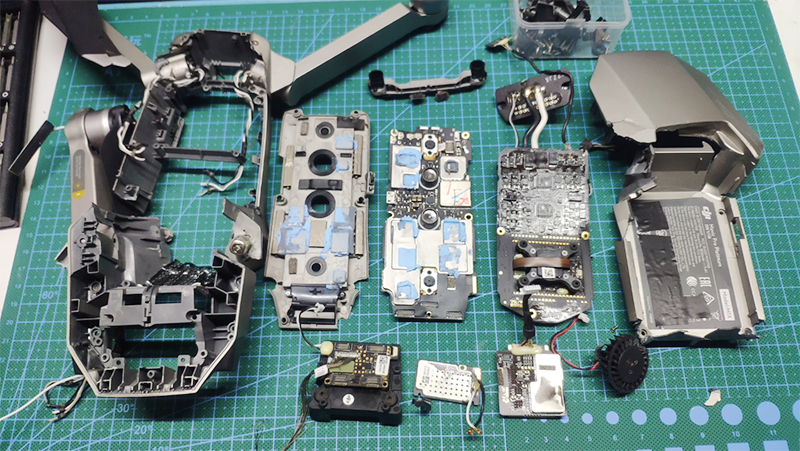

Basic Structure of Drones

A drone typically consists of several key components, each requiring an efficient thermal management system to ensure stable operation during flight. The basic structure of a drone includes the following core parts:

● Airframe and Structure: The airframe is typically made of lightweight yet strong materials such as carbon fiber or aluminum alloy. It provides the structural support for the entire system. The airframe needs to ensure sufficient strength to withstand vibrations and external forces during flight, while also offering good heat dissipation performance to efficiently transfer internal heat to the external environment.

● Power System: This includes the battery, motor, and drive system. The battery powers the drone, but it generates a lot of heat during charging and discharging. Motors and drive systems also produce significant heat during high-load operation. Efficient dissipation of this heat is a key issue in thermal management.

● Flight Control System and Sensors: The flight control system is responsible for drone operation and data processing, which typically includes high-performance processors, sensors (such as GPS, IMU, etc.), and other electronic components. These components need to process large amounts of data efficiently, and prolonged operation generates heat, which requires effective cooling solutions.

● Communication and Navigation Systems: The communication module exchanges data with the ground control station, while the navigation system handles positioning and path planning. Although these components generate less heat, maintaining stable temperatures is still critical to ensure their proper functioning.

Heat Sources and Heat Dissipation Needs

During flight, especially under high load, long-duration flights, or complex task execution, multiple key components of the drone continuously generate heat. For example, the battery generates a lot of heat during discharge, while motors and flight control systems also produce significant heat during operation. If this heat is not dissipated in time, it could lead to reduced battery life, motor performance degradation, or system failure. Therefore, designing a thermal management system to quickly transfer heat away from the core components and prevent overheating is an essential task in drone design.

The Role of Thermal Interface Materials

Thermal interface materials (TIMs) play a crucial role in drone thermal management. Their main function is to quickly transfer the heat generated by components to the heat sink or external environment, preventing the buildup of heat within critical components. TIMs need to have excellent thermal conductivity, environmental adaptability, compressibility, and long-term stability. Choosing the right TIM can significantly improve thermal management efficiency, ensuring the drone maintains optimal performance under various operating conditions.

NFION Thermal Material Solutions

NFION provides a range of thermal material solutions for drone applications, primarily including thermal silicone pads and thermal gels. These materials offer advantages in terms of heat conductivity, adaptability, and compressibility. They can also be customized based on specific application needs, ensuring that drones maintain optimal performance in various environments.

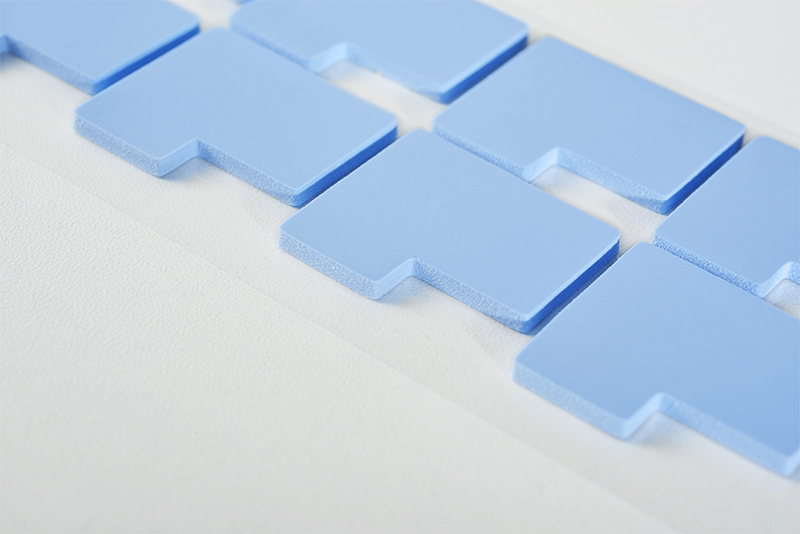

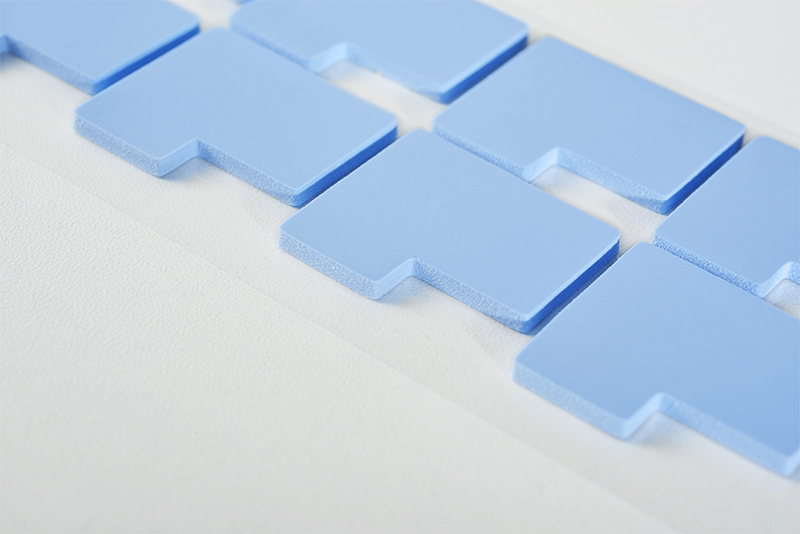

Application of Thermal Silicone Pads in Drone Thermal Management

Thermal silicone pads are widely used in drone thermal management due to their excellent thermal conductivity and compressibility. Their main advantage is the ability to achieve uniform heat transfer across different shapes and surface conditions, improving overall heat dissipation efficiency.

Specific Applications

● Battery Heat Management: Drone batteries generate significant heat during charging and discharging. If this heat cannot be dissipated effectively, the battery may overheat, reducing its lifespan or causing safety issues. Thermal silicone pads quickly transfer the heat generated by the battery to heat sinks or thermal exchangers, ensuring the battery operates within a safe temperature range.

● Processor and Sensor Cooling: The processors and sensors in drones generate significant heat during flight control and data processing. Thermal silicone pads fill the gaps between electronic components and heat sinks, reducing thermal resistance and ensuring that these high-performance components maintain optimal working temperatures.

Advantages

● High Heat Conductivity: Thermal silicone pads have excellent thermal conductivity, which allows them to transfer heat from components to heat sinks quickly, ensuring the components stay within safe operating temperatures.

● Good Compressibility: Thermal silicone pads maintain stable thermal performance under varying pressures, adapting to complex and irregular component surfaces, ensuring tight contact between the material and the surface for maximum heat transfer efficiency.

● Stable Environmental Adaptability: Thermal silicone pads can operate stably in extreme temperature, low temperature, and humid environments, meeting the thermal management needs of drones under various conditions.

Application of Thermal Gels in Drone Thermal Management

Thermal gels are another highly effective thermal material, typically used to fill gaps between densely packed components. Their fluidity and stickiness allow them to fill small voids, ensuring more uniform heat transfer.

Specific Applications

● Motor and Drive System Cooling: The motors and drive systems in drones generate significant heat under heavy load, requiring an efficient thermal management solution. Thermal gels quickly transfer heat from the motor to the heat sink, preventing motor performance degradation or failure due to overheating.

● High-Performance Electronic Components: High-performance components like FPGAs and GPUs in drones generate substantial heat while processing complex tasks. Thermal gels fill the gaps between these components and heat sinks, improving thermal contact and ensuring stable system operation.

Advantages

● Excellent Heat Conductivity: Thermal gels provide high thermal conductivity, quickly transferring heat from high-temperature components to the heat sink, maintaining the system’s safe operating temperature.

● Good Filling Properties: Thermal gels have strong flow properties, enabling them to fill the small voids between electronic components and heat sinks, ensuring efficient thermal paths and improving heat dissipation.

● Strong Stability: Thermal gels perform exceptionally well in extreme temperatures, low temperatures, and humid environments, making them ideal for drone operations under various environmental conditions.

Comprehensive Advantages of NFION Thermal Materials

Efficient Heat Dissipation, Ensuring Stability

NFION's thermal silicone pads and thermal gels significantly improve the thermal management efficiency of drones, ensuring that electronic components maintain stable operation under high load, preventing performance degradation or failure due to overheating.

Customized Solutions

NFION offers tailor-made thermal material solutions based on the specific heat dissipation needs of different drones. Whether it's for batteries, motors, processors, or other critical components, NFION provides the most suitable thermal materials for maximum heat dissipation performance.

Environmental Friendliness and Reliability

NFION’s thermal silicone pads and thermal gels comply with international environmental standards, using non-toxic, pollution-free materials that ensure environmental friendliness. At the same time, the high performance and long lifespan of these materials ensure stable operation even under harsh environmental conditions, greatly improving the reliability of drones.

Conclusion

As drone technology continues to evolve, thermal management issues become increasingly prominent, especially for high-performance and long-duration flights. The choice of thermal materials is critical in ensuring the proper functioning of drone systems. NFION’s thermal silicone pads and thermal gels, with their excellent heat conductivity, good compressibility, environmental adaptability, and cost-effectiveness, provide efficient and reliable solutions for drone heat dissipation. By using NFION’s thermal materials, drone manufacturers can improve product performance and reliability while meeting thermal management demands, thus gaining a competitive edge in a rapidly growing market.

CN >

CN >