Thermal Management Challenges in Intelligent Cockpit Domain Controllers

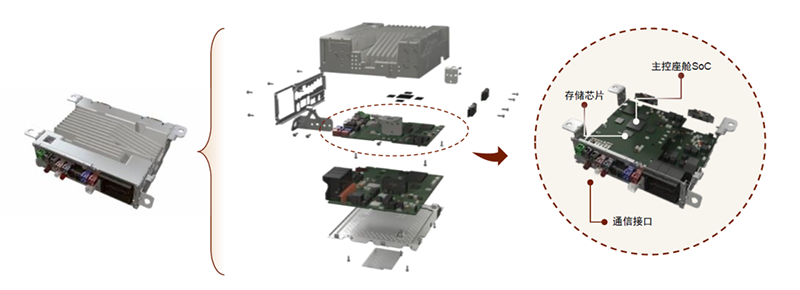

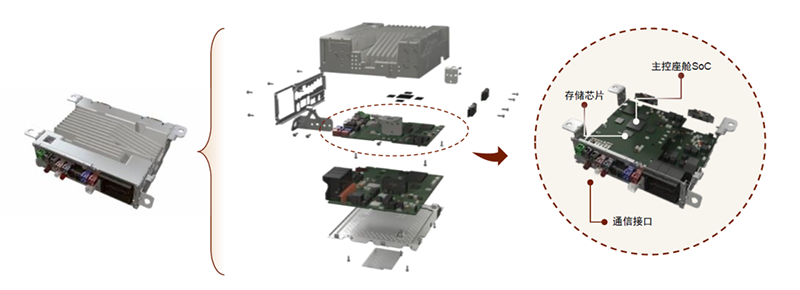

With the rapid development of automotive intelligence, the Intelligent Cockpit Domain Controller (CDC) has become the core component for enhancing the driving experience. This controller integrates the dashboard, central control screen, HUD (head-up display), and in-car entertainment system, handling complex computing and high-speed data processing tasks. However, such a high level of integration has led to significant power consumption, resulting in heat buildup inside the device.

If the heat is not effectively dissipated, it can cause chip performance degradation, system instability, shortened lifespan, and even safety hazards. Therefore, an effective thermal management solution is crucial for intelligent cockpit domain controllers, with thermal interface materials (TIMs) playing a key role.

Key Heat Sources and Thermal Dissipation Requirements in Cockpit Domain Controllers

The primary heat-generating components in cockpit domain controllers include:

● High-performance SoC (System-on-Chip): Handles intensive computing tasks, generating a substantial amount of heat that must be efficiently transferred to a cooling structure.

● Memory Chips (DRAM, eMMC, etc.): Prolonged operation leads to heat buildup, requiring stable thermal management materials to maintain efficient data processing.

● Power Management IC (PMIC): Converts and regulates power, generating heat during operation, which must be managed to prevent overheating.

To address these thermal challenges, thermal interface materials (TIMs), heat sinks, cooling fans, and liquid cooling systems are commonly used. Among these, thermal materials directly impact heat transfer efficiency and play a decisive role in overall performance.

Selection of Thermal Management Materials for Cockpit Domain Controllers

Based on the thermal management needs of cockpit domain controllers, the following thermal materials can be selected:

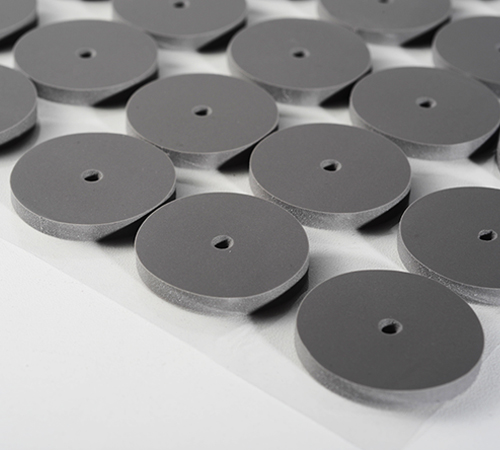

1. Thermal Grease

● Features: High thermal conductivity (1-6 W/m·K), low thermal resistance, excellent wettability, suitable for filling gaps between chips and heat sinks.

● Application: Used between SoC/GPU and heat sinks to enhance thermal contact efficiency.

● Pros and Cons: Offers excellent thermal performance but may dry out or experience pump-out effects over time, reducing reliability.

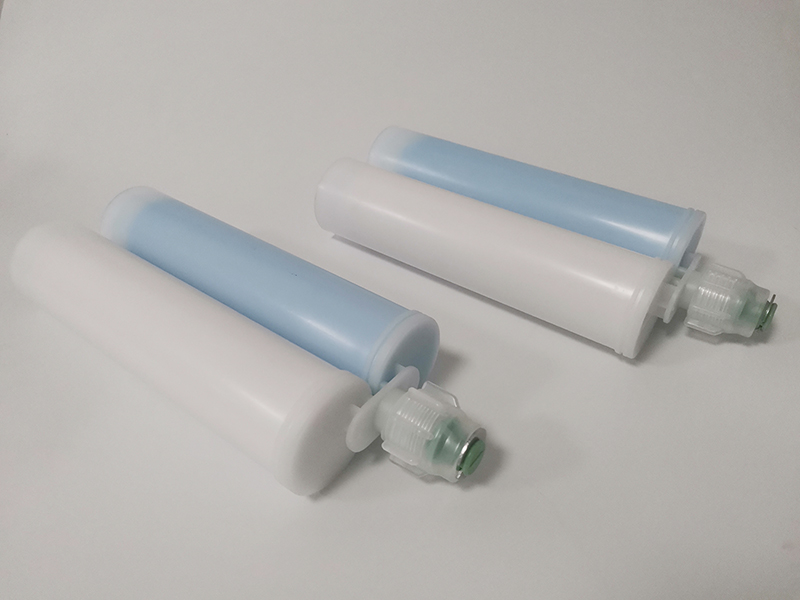

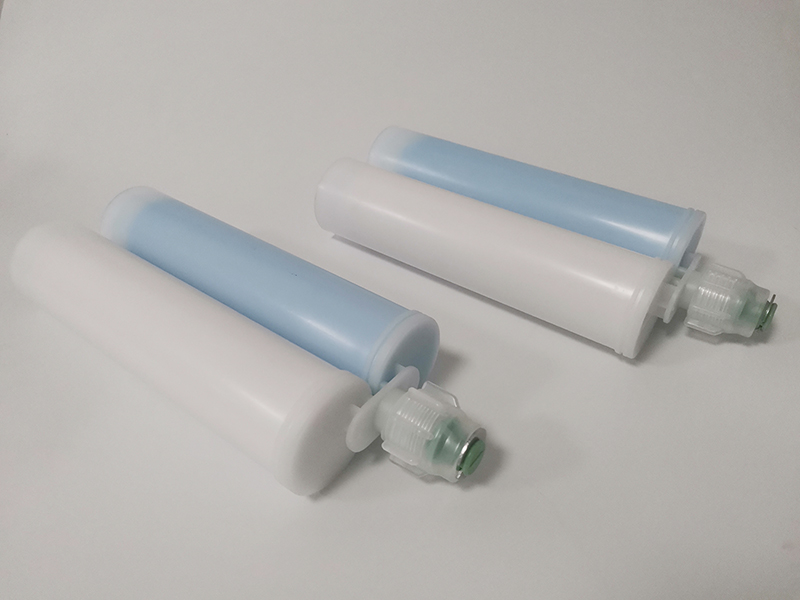

2. Thermal Gel

● Features: Low contact thermal resistance (1.5-10 W/m·K), self-leveling capability, long-term stability.

● Application: Used for high-power SoCs, memory chips, and other key heat sources as a long-term alternative to thermal grease.

● Pros and Cons: Requires no reapplication and is suitable for mass production but has a higher cost than thermal grease.

3. Thermal Adhesive

● Features: Provides both thermal conductivity and adhesion (0.8-2 W/m·K), enabling heat dissipation and component fixation.

● Application: Used to bond power management ICs (PMICs) and small heat sinks, simplifying structural design.

● Pros and Cons: Strong adhesion but non-removable after curing.

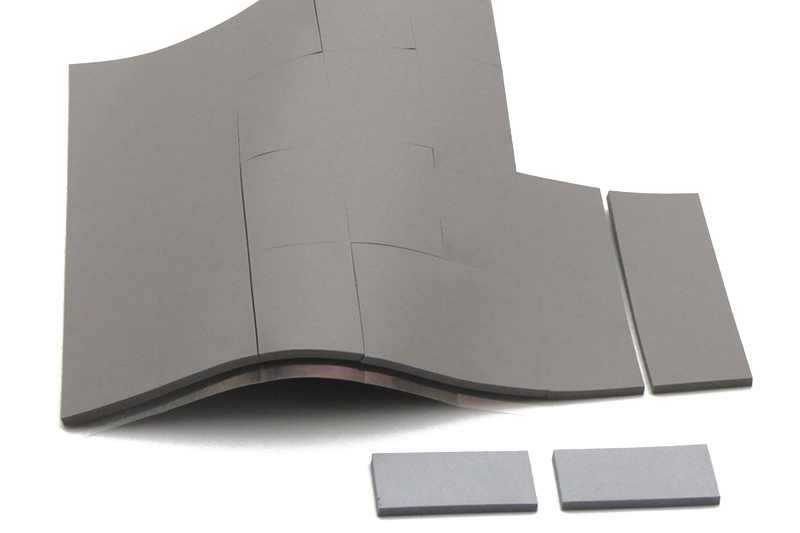

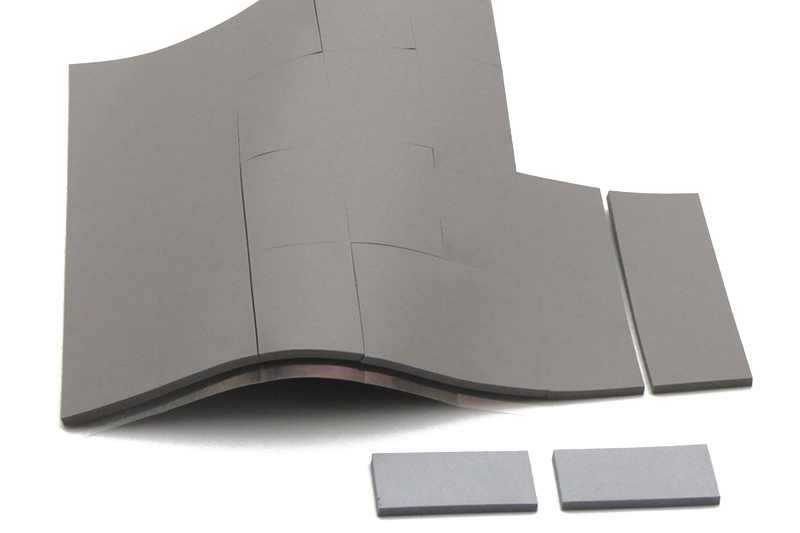

4. Thermal Conductive Pad

● Features: Thermal conductivity of 1-12 W/m·K, compressible, ideal for filling gaps of varying heights.

● Application: Used between PCBs and metal casings or for SoC chip stacking.

● Pros and Cons: Easy to install but has slightly lower thermal conductivity compared to grease and gel.

5. Thermal Potting Compound

● Features: Thermal conductivity of 0.8-2 W/m·K, excellent fluidity, provides complete encapsulation, enhancing heat dissipation, electrical insulation, waterproofing, dust protection, and shock resistance.

● Application: Used for power modules, sensors, power electronics, and other components requiring both heat dissipation and protection.

● Pros and Cons: Offers long-term stability but is non-removable after curing, making it suitable for high-reliability applications.

Recommendations for Optimizing the Thermal Management of Cockpit Domain Controllers

To ensure long-term stable operation, the following optimization strategies are recommended:

1. Combining Different Thermal Materials

● Use thermal gel or high-performance thermal grease between SoC chips and heat sinks for optimal thermal contact.

● Fill the gap between PCB and casing with thermal pads to improve overall heat dissipation.

● Apply thermal adhesive on power management ICs and small heat sinks for both thermal conduction and component fixation.

● Utilize thermal potting compound in power modules and sensors to enhance heat dissipation, waterproofing, and vibration resistance.

2. Optimizing Heat Dissipation Structures

● Choose efficient heat sink materials like aluminum alloys or graphite sheets to enhance heat spreading.

● Use vapor chambers or heat pipes for faster heat transfer.

● Implement active cooling fans or liquid cooling in high-end cockpit domain controllers for enhanced cooling efficiency.

Application of NFION Thermal Materials in Cockpit Domain Controllers

As a professional thermal materials supplier, NFION offers a full range of high-performance thermal management solutions for cockpit domain controllers:

● High-performance thermal grease : Ideal for high-power chips, improving heat dissipation.

● Thermal gel : Low thermal resistance, long-lasting stability, suitable for automated production.

● Thermal adhesive : Provides both thermal conductivity and adhesion, simplifying structural design.

● Thermal conductive pad : High thermal efficiency, suitable for chip stacking and PCB gap filling.

● Thermal potting compound : Designed for power modules and sensors, offering heat dissipation, protection, and vibration resistance.

NFION’s thermal solutions are widely used in automotive electronics, ensuring the stable operation of cockpit domain controllers even in extreme conditions.

Conclusion

Thermal management is crucial for ensuring the stability and longevity of intelligent cockpit domain controllers. By selecting appropriate thermal interface materials and optimizing heat dissipation structures, heat resistance can be minimized, and thermal efficiency can be maximized, ensuring reliable long-term operation.

As automotive intelligence advances, high-performance thermal materials will play an increasingly vital role in cockpit domain controllers. NFION is committed to delivering efficient and reliable thermal management solutions to support innovation in intelligent cockpit technology.

CN >

CN >