You're probably wondering how the ultra-thin modern TV sets silently "digest" the enormous heat generated during operation, ensuring the picture remains consistently clear, smooth, and vibrant. The answer lies in TV thermal management technology. It's not only the cornerstone for ensuring stable TV performance but also key to enhancing user experience and extending product life.

TV Thermal Management: More Than Just Cooling, It's the Guardian of Performance and Lifespan

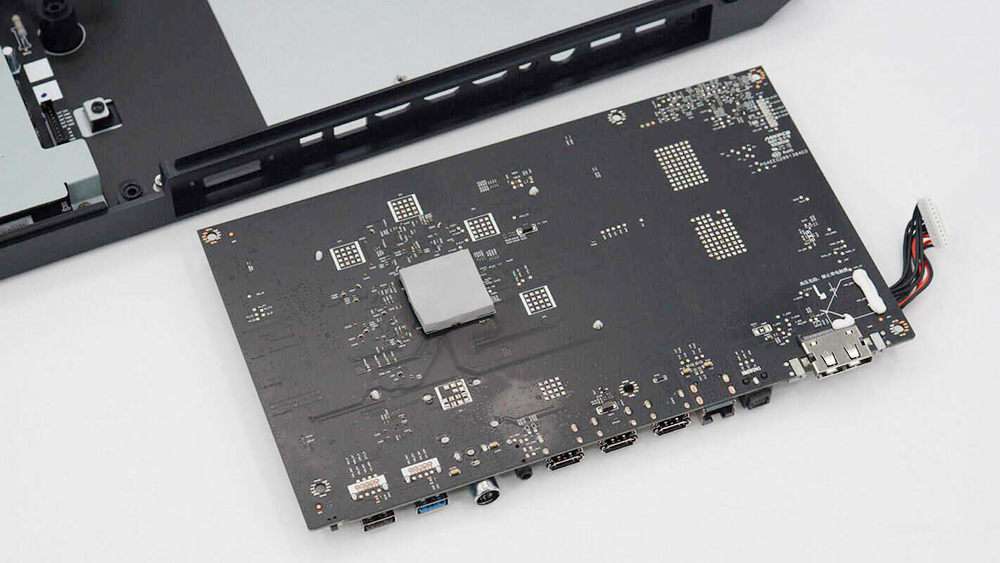

As display technology rapidly advances, TVs are becoming thinner and lighter, with larger screens and higher internal integration, leading to increased power consumption. Core components like LED/LCD backlight modules, high-performance System-on-Chips (SoCs) for image processing, power modules, and audio systems all generate significant heat during operation. If this heat isn't effectively dissipated, it can lead to issues ranging from flickering screens, color distortion, and reduced brightness, to more severe problems like system crashes or even component damage, drastically shortening the TV's lifespan.

Therefore, an efficient thermal management solution for TVs isn't just about simple "cooling"; it's a comprehensive system engineering effort designed to:

● Ensure Stable Picture Quality: Maintain the display panel and backlight module at optimal operating temperatures to guarantee color accuracy, brightness uniformity, and contrast performance.

● Enhance System Performance: Prevent high-performance SoCs from throttling due to overheating, ensuring a smooth UI experience and high-definition video playback capabilities.

● Extend Product Lifespan: Reduce the operating temperature of critical electronic components, effectively slowing down their aging process and prolonging the TV's service life.

● Optimize User Experience: Minimize noise (like fan noise) or localized hot spots caused by overheating, improving user viewing comfort.

Core Technical Solutions for TV Thermal Management

Achieving efficient thermal management requires the integrated application of various technical methods, from controlling heat generation at the source to optimizing heat transfer paths and finally, efficient heat dissipation at the end, forming a complete closed loop.

1. Heat Source Management and Optimization

● Low-Power Component Selection: Prioritize selecting LED backlight beads, low-power SoC chips, and power management ICs that generate less heat and have higher conversion efficiency. This is the most direct way to reduce heat generation at the root.

● Optimized Circuit Design: Streamline circuit design to reduce unnecessary energy loss, for example, by using more efficient DC-DC converters.

● Intelligent Power Management: Intelligently adjust the power supply voltage and current for each module based on the TV's operating status (e.g., standby, playback, HDR mode), reducing unnecessary power consumption and heat.

2. Heat Transfer Path Optimization

Efficient heat transfer from the heat source to the dissipation surface often involves the following materials and structures:

● Thermal Interface Materials (TIMs):

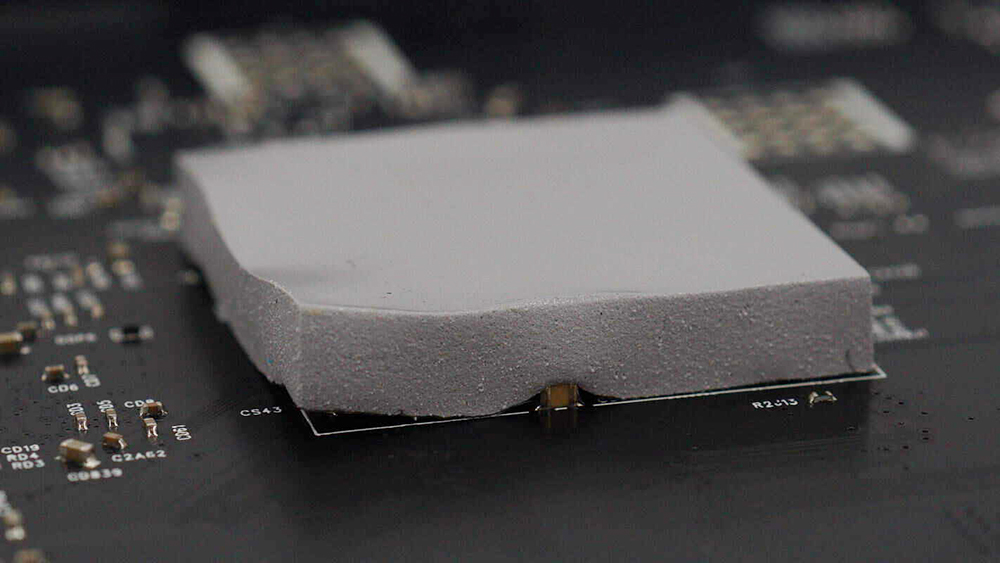

● Thermal Gels/Thermal Pads: Fill tiny gaps between chips and heat sinks, providing a flexible connection and improving heat transfer efficiency. They offer good thermal conductivity, electrical insulation, and ease of application.

● Thermal Graphite Sheets: Possess extremely high in-plane thermal conductivity, often used to rapidly and uniformly spread heat from hot spots, especially suitable for ultra-thin designs.

● Thermal Grease: Ideal for intimate contact between precision chips and heat sinks, providing excellent thermal conductivity.

● Thermal Structure Design:

● Vapor Chambers/Heat Pipes: These advanced phase-change cooling technologies use the evaporation and condensation cycle of an internal working fluid to quickly transfer heat from a heat source to a more distant dissipation area, proving highly effective for high heat flux density chips.

● Aluminum Alloy Backplates/Middle Frames: Many mid-to-high-end TVs directly utilize metal backplates or middle frames as primary heat dissipation surfaces. The excellent thermal conductivity of metal helps rapidly transfer internal heat to the outside of the TV, dissipating it through natural convection or radiation.

● Internal Airflow Channel Design: Reasonably plan internal airflow paths within the TV, utilizing the principle of hot air rising to guide hot air out from the top or exhaust vents, and drawing in cool air from the bottom or sides, forming effective natural convection.

3. Efficient Heat Dissipation Technologies

● Natural Convection Cooling: This is the most common and economical cooling method. Through openings on the TV casing, hot internal air rises and is expelled, while cooler external air flows in to replenish, achieving silent cooling without additional fans.

● Forced Convection Cooling (Fan Cooling): For high-performance, high-heat-generating TVs (like some high-end Mini LED TVs or professional displays), miniature fans may be integrated to force air circulation, more efficiently carrying away heat. In this case, fan noise control and lifespan are critical considerations.

● Radiation Cooling: Increase the infrared emissivity of material surfaces to dissipate heat in the form of electromagnetic waves.

● Liquid Cooling: In a very small number of ultra-high-end or specialized applications, liquid cooling technology might be considered, but it is not yet widespread in consumer TVs due to cost, complexity, and reliability.

Case Study: Thermal Management Challenges and Solutions for Mini LED TVs

Taking the currently popular Mini LED TVs as an example, their thermal management faces unique and more severe challenges:

● High Brightness Leading to High Heat: Mini LED backlighting achieves extremely high peak brightness and contrast through tens of thousands of tiny LED beads for local dimming. This means a sharp increase in the number of LED beads per unit area, leading to a significant rise in power consumption and heat generation.

● Ultra-Thin Trend: To achieve an ultimate aesthetic, Mini LED TVs are often made extremely thin, leaving very limited space for cooling structures.

To address these challenges, Mini LED TVs typically adopt more advanced and precise composite thermal management solutions:

● COB (Chip-on-Board) Packaging Technology: Mini LED chips are directly packaged onto the substrate, reducing the thermal resistance of traditional LED packaging structures and improving heat dissipation efficiency.

● Large-Area Copper Foil/Graphite Sheet Heat Sinks: Large areas of copper foil or highly thermally conductive graphite sheets are laid beneath the Mini LED backlight module to rapidly and uniformly transfer heat generated by the LED beads to the entire back panel.

● High Thermal Conductivity Aluminum Alloy Backplate/Middle Frame: The entire metal backplate is used as a large heat sink to transfer heat outwards.

● Precision Filling with Thermal Gels/Pads: Ensure intimate contact between key heat sources like LED driver chips and the cooling structure, maximizing heat transfer efficiency.

● Intelligent Temperature Control Algorithms: Real-time monitoring of internal TV temperature using temperature sensors like NTC thermistors. When the temperature is too high, the system intelligently adjusts the LED backlight brightness or SoC frequency, ensuring the TV doesn't overheat without compromising the user experience.

Future Outlook: Smarter, More Efficient, and Greener Thermal Management

As TV display technology continues to evolve, 4K, 8K, and even higher resolution screens will become mainstream, and features like HDR and high refresh rates will demand even greater processor performance. All of this means that the heat generated by future TVs will continue to increase. At the same time, consumers' pursuit of extreme TV aesthetics also places more stringent demands on cooling design.

Future TV thermal management will move in the following directions:

● Material Innovation: Developing new thermal materials with higher thermal conductivity, lighter weight, and greater flexibility.

● Structural Optimization: Utilizing advanced design methods like bionics and topology optimization to create more compact and efficient cooling structures.

● AI and Big Data Applications: Using AI algorithms to predict and optimize heat distribution, enabling more precise temperature control and smarter power management.

● Environmental Friendliness: Greater consideration for the environmental aspects of cooling solutions, reducing reliance on rare materials, and improving recyclability.

TV thermal management solutions are complex system engineering efforts that integrate materials science, thermodynamics, structural design, and intelligent control. They silently protect our audio-visual experience behind the scenes and are the solid guarantee of high performance and long life for modern TVs. With continuous technological advancements, we have every reason to believe that future TVs will achieve new breakthroughs in heat dissipation, bringing us an even more extreme and comfortable viewing experience.

CN >

CN >