With the rapid development of new energy vehicles, charging stations, as a core infrastructure, are facing dual challenges in technical performance and environmental adaptability. The demand for highpower fast charging has significantly increased the heat generation of internal components, making thermal management crucial to ensuring stable operation and extending the lifespan of charging stations. Shenzhen Nuofeng Electronic Technology Co., Ltd. leverages its expertise in thermal materials to provide comprehensive thermal management solutions, helping the industry overcome technical bottlenecks.

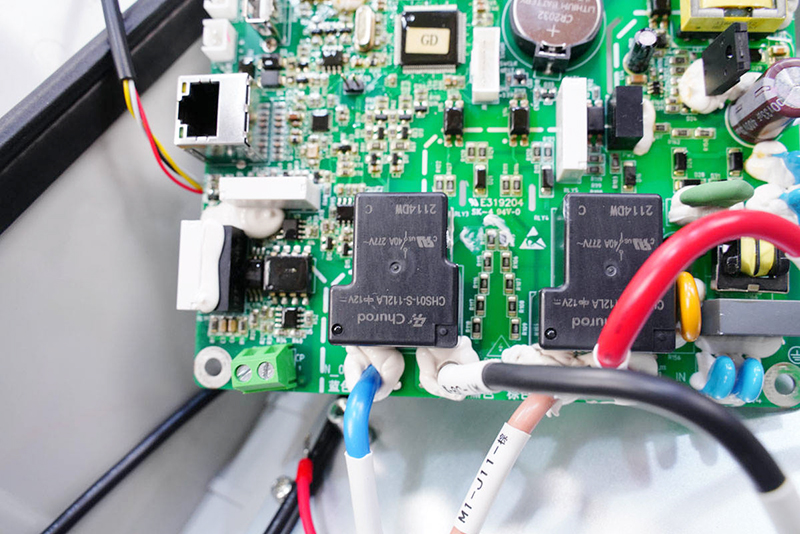

Modern charging stations often use highvoltage DC fast charging technology. Key components include power modules (e.g., IGBT), control circuit boards, power transformers, and connectors. These components generate substantial heat during highload operations, which, if not dissipated effectively, may lead to:

1. Performance Degradation of Components: Excessive temperatures can increase the conduction resistance of semiconductor devices, reducing power conversion efficiency.

2. Reduced Equipment Reliability: Prolonged exposure to high temperatures accelerates material aging and may cause failures.

Thus, equipping charging stations with efficient thermal management materials and solutions not only improves operational efficiency but also extends equipment lifespan and ensures safety.

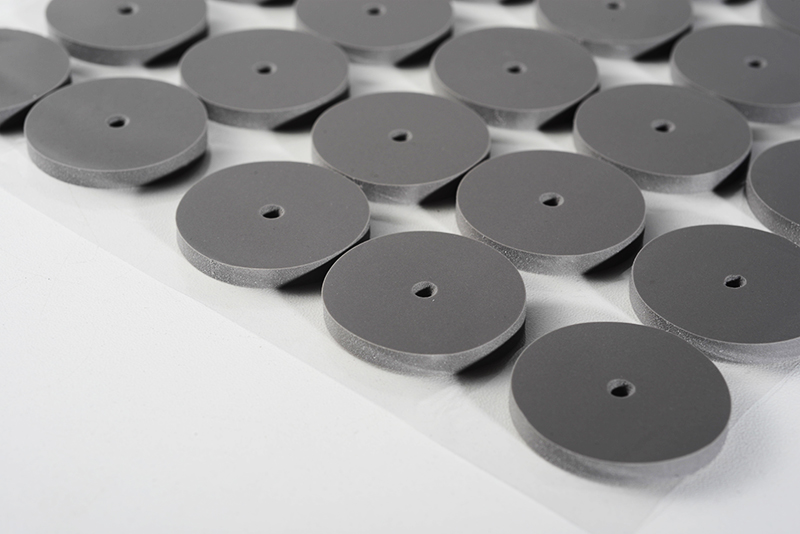

Applications: Ideal for heat transfer in IGBT modules and power circuit boards.

Applications: Used for efficient heat transfer between power modules and heat sinks.

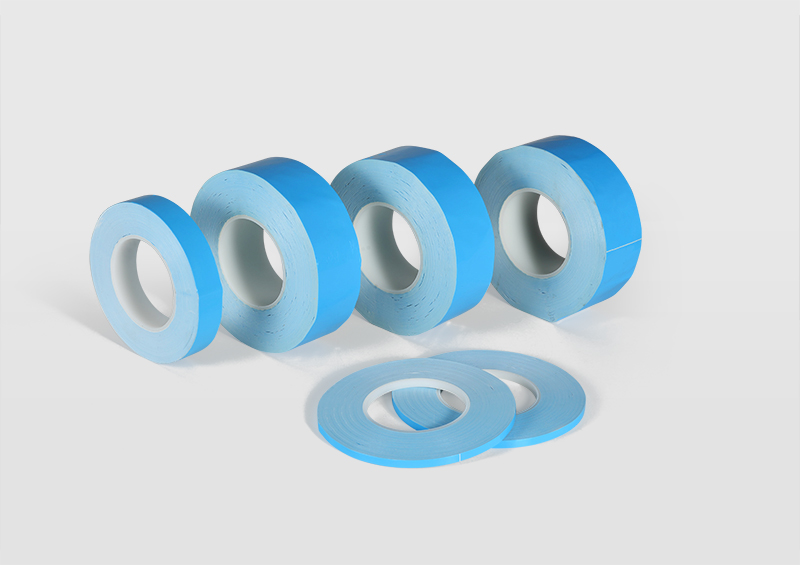

3. Double-Sided Thermal Tape

Applications: Ideal for bonding power transformers and heat sinks.

4. Thermal Adhesive Glue

Applications: Used for securely bonding heat sinks to components, ensuring highstrength and efficient heat dissipation.

5. Thermal Potting Compound

Applications: Suitable for thermal potting and protection of critical components like power modules, inductors, and transformers.

6. Thermal Gel

Applications: Ideal for highperformance thermal management in IGBT modules and power modules.

7. Phase Change Thermal Interface Materials

8. Insulated Thermal sheets

Applications: Widely used for insulation and thermal conduction in control circuits and power modules.

NFION’s thermal management materials have been successfully implemented in various DC fastcharging station projects to address thermal management challenges:

1. 500kW HighPower Charging Station Project: Combined use of thermal silicone pads and thermal grease significantly reduced the operating temperature of power modules, improving efficiency and reliability.

2. Outdoor Charging Stations: For hightemperature and highhumidity environments, waterproof and weatherresistant insulated thermal pads, thermal doublesided tapes, and thermal potting compounds ensured efficient heat dissipation and longterm stability.

3. Compact Charging Stations: In spaceconstrained applications, thermal gels and phase change materials enhanced thermal interface performance and optimized automated assembly efficiency.

CN >

CN >