In modern high-tech applications, laser power equipment has become a core component in industries such as industrial manufacturing, medical devices, and communications, thanks to its efficiency and reliability. However, as laser power operates at high power levels, it generates significant heat, which, if not managed effectively, can impact its performance and lifespan.

To address this need, NFION has developed a range of high-performance thermal interface pads to deliver stable and efficient thermal management solutions for laser power systems.

Thermal Management Challenges in Laser Power Systems

The Importance of Heat Management

Laser power systems often operate under high current and voltage, generating substantial heat. Ineffective heat dissipation can result in the following issues:

● Performance Decline: High temperatures reduce power conversion efficiency and affect output stability.

● Component Wear: Prolonged exposure to heat accelerates component aging, shortening the device's lifespan.

● Safety Risks: Overheating can lead to equipment failure or even fire hazards.

Limitations of Traditional Thermal Management Solutions

Although various cooling methods and materials exist, the compact and high-power-density nature of laser power systems poses unique challenges. Traditional solutions like fans or metal heat sinks often struggle to balance performance with space constraints.

Technical Features of NFION Thermal Interface Pads

Superior Thermal Conductivity

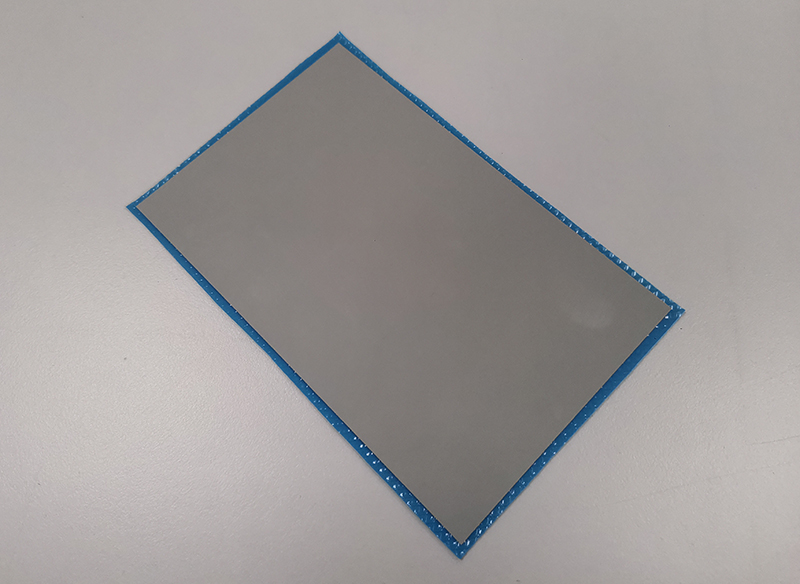

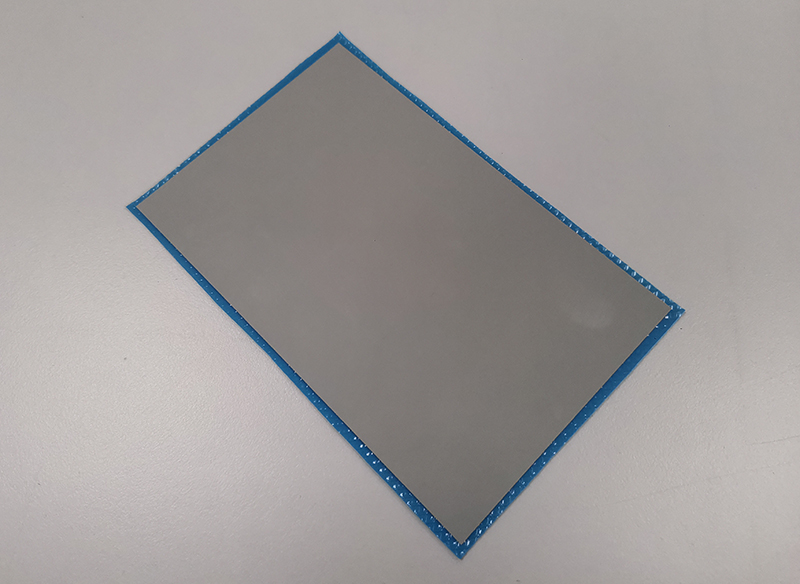

NFION thermal interface pads are composed of high-performance thermal fillers and silicone-based materials, achieving a thermal conductivity range of 1.5 W/m·K to 12 W/m·K, enabling rapid heat transfer from heat sources to heat sinks or casings.

High Conformability and Excellent Fit

These pads offer outstanding softness, ensuring tight contact with uneven surfaces and minimizing thermal resistance.

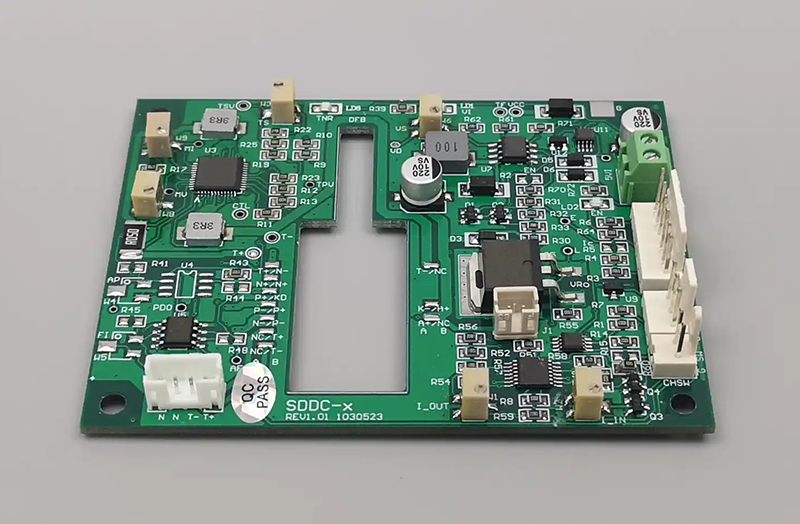

Excellent Electrical Insulation

In high-voltage environments, NFION thermal interface pads provide excellent electrical insulation (breakdown voltage exceeding 10 kV/mm), ensuring safe operation.

High Reliability and Durability

With a broad operating temperature range of -40°C to +200°C, these pads maintain stable thermal and mechanical properties even under extreme conditions, meeting the demands of laser power systems.

Applications of NFION Thermal Interface Pads in Laser Power Systems

Heat Management for Critical Components

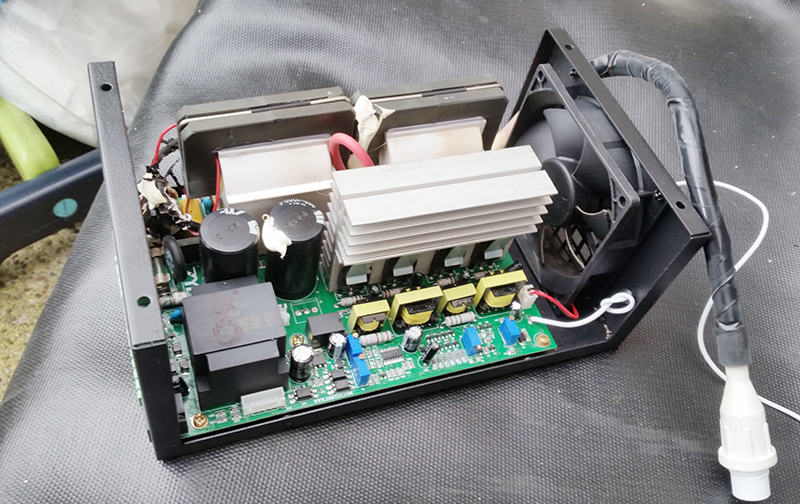

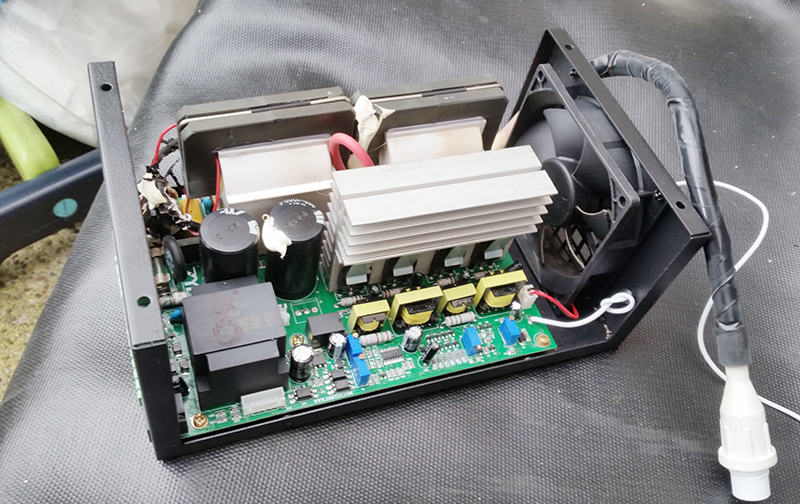

Key areas in laser power systems where thermal interface pads are most effective include:

● Power Modules: Ensuring optimal heat transfer between power conversion modules and heat sinks.

● Inductors and Transformers: Dissipating heat from coils and cores to prevent performance degradation.

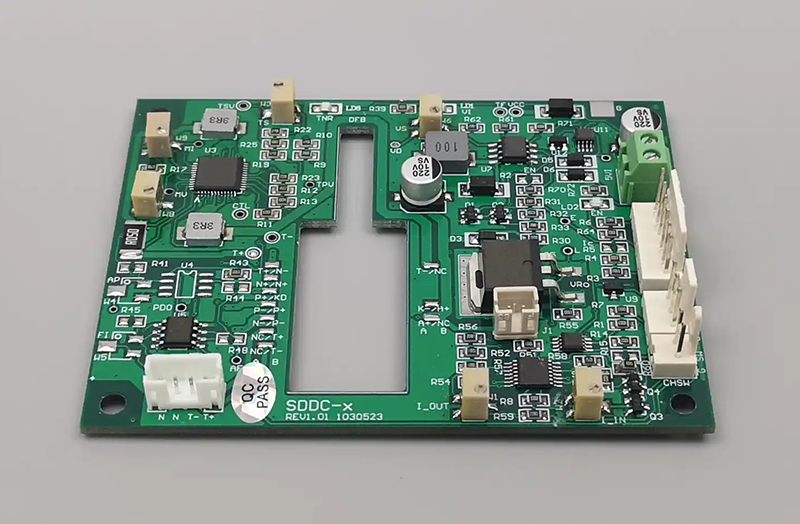

● Control Circuit Boards: Enhancing overall heat dissipation by filling gaps between PCBs and enclosures.

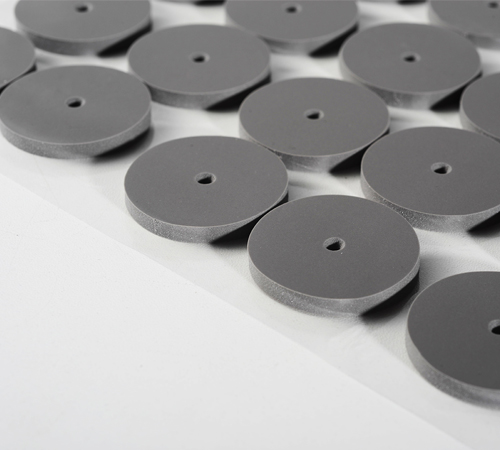

Ease of Installation

NFION thermal interface pads are easy to cut and customize, accommodating the specific shapes and sizes of laser power systems. This simplifies the installation process and enhances manufacturing efficiency.

Value and Benefits for Customers

Enhanced Equipment Performance

Efficient thermal management significantly reduces operating temperatures, improving electrical performance and output stability.

Extended Device Lifespan

By reducing heat-induced wear on components, thermal interface pads extend the service life of laser power systems, lowering maintenance and replacement costs.

Greater Design Flexibility

With lightweight and high-performance characteristics, NFION thermal interface pads enable more compact and integrated designs for laser power systems.

Conclusion

Thermal management is critical for the reliable operation of laser power systems. NFION thermal interface pads provide excellent thermal conductivity, electrical insulation, and reliability, offering an effective thermal management solution for the industry.

NFION is committed to developing advanced thermal materials to support customer needs in heat management. For more information, please visit our website or contact our technical team.

CN >

CN >