As LED lighting technology rapidly advances, the demand for high-efficiency, long-lasting LED luminaires is on the rise. However, LED lights generate significant heat during operation, and excessive temperatures not only reduce brightness and light efficiency but can also cause light degradation and failure of electronic components, thereby shortening product lifespan. To tackle this challenge, Nfion Electronic Technology Co., Ltd. has introduced a range of innovative thermal conductivity and heat dissipation bonding solutions designed to provide excellent thermal management performance for the LED lighting industry.

The Importance and Challenges of LED Heat Dissipation

The widespread application of LED light sources in the lighting industry is due to their energy efficiency and environmental benefits. However, as semiconductors, LEDs generate significant heat when current flows through them. If this heat is not effectively dissipated, the chip temperature will rise sharply, negatively impacting the luminous efficiency and lifespan of the LED. Studies have shown that for every 10°C increase in LED operating temperature, its lifespan may be cut in half. Therefore, efficiently transferring heat from the LED chip to external heat sinks and ultimately dissipating it into the air is key to improving LED performance and durability.

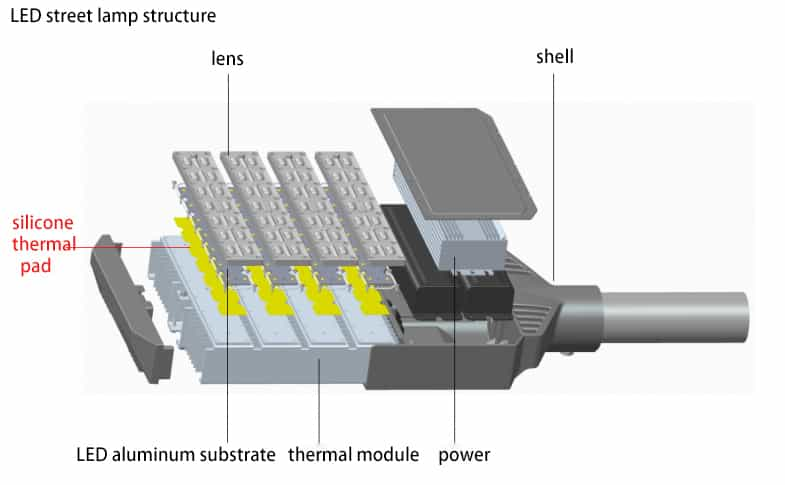

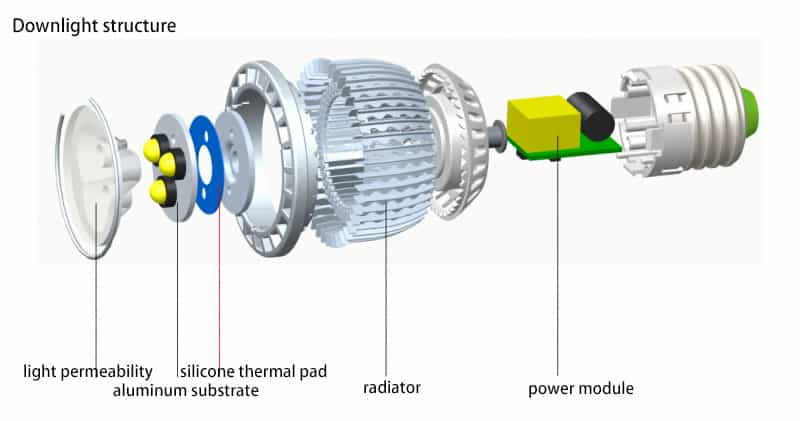

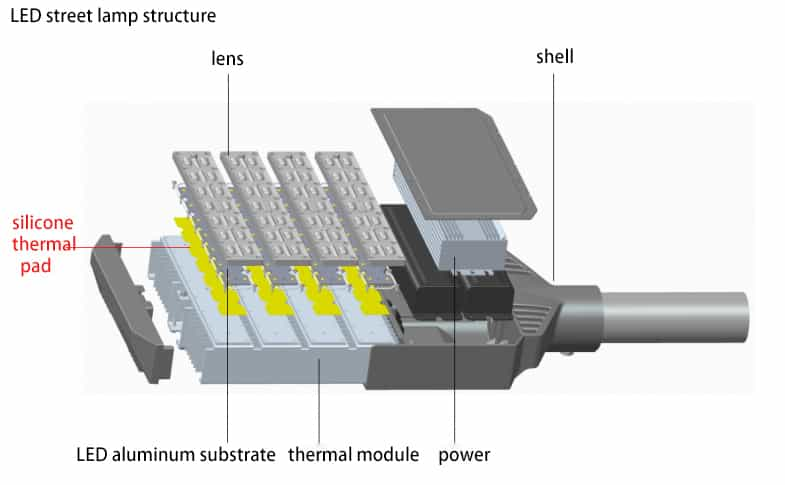

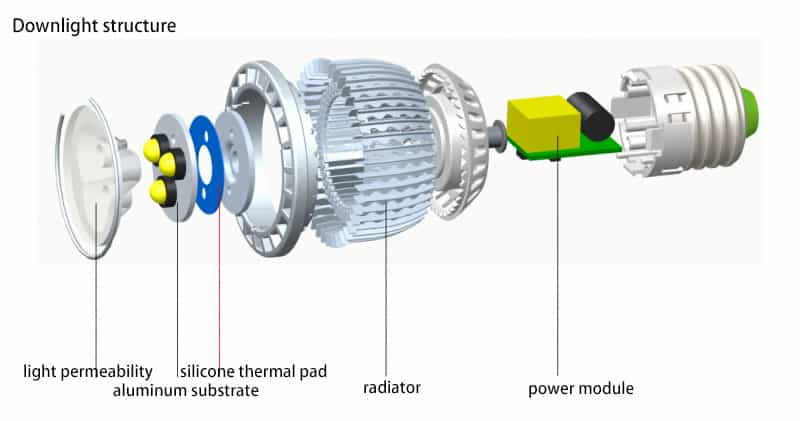

Traditional LED heat dissipation methods rely on metal heat sinks or fans. However, these approaches are insufficient for high-power, densely packed LED applications, and they often increase the size and cost of the product. Additionally, the adhesives and thermal materials used in the bonding and assembly process directly impact heat dissipation efficiency, mechanical strength, and overall production processes.

Nfion's Innovative Thermal Conductivity and Heat Dissipation Bonding Solutions

To address the challenges of LED heat dissipation, Nfion has launched a new range of thermal conductivity and heat dissipation bonding solutions, including thermal conductive adhesive, thermal grease, and silicone thermal pads. These products provide high-efficiency heat transfer, reliable bonding, and stable heat dissipation, offering comprehensive solutions tailored for LED lighting applications.

1. High-Efficiency Thermal Conductive Adhesive

Nfion's thermal conductive adhesive features excellent thermal conductivity, with a thermal conductivity coefficient of over 2.0 W/m·K. This adhesive rapidly transfers the heat generated by LED chips to the heat sink, reducing chip temperature and extending the lifespan of LED lights. In addition to superior heat transfer, it offers high-strength mechanical bonding, effectively replacing traditional mechanical fasteners, simplifying the assembly process, increasing production efficiency, and reducing costs. Furthermore, after curing, the interface layer formed by the thermal conductive adhesive has extremely low thermal resistance, further optimizing heat transfer pathways.

2. Thermal Grease

Nfion's thermal grease is a high-conductivity, low thermal resistance interface material with a thermal conductivity coefficient of 3.0 W/m·K. It is especially suitable for managing heat transfer between the LED chip and the heat sink. Thermal grease can effectively fill irregular surfaces, ensuring seamless heat transfer to the heat sink, thereby improving overall dissipation efficiency. Its excellent long-term stability and resistance to aging allow it to maintain high-efficiency thermal performance even under extreme temperature conditions, making it ideal for high-power LED applications.

With its low viscosity, thermal grease is easy to apply and can quickly fill small gaps in LED modules, making it an ideal choice for large-scale production. Moreover, its compatibility with automated processes enhances production efficiency and reduces manual labor.

3. Silicone Thermal Pads

Nfion’s silicone thermal pads are flexible, compressible thermal interface materials designed for LED applications requiring the filling of larger gaps or uneven surfaces. With a thermal conductivity coefficient of 1.5 W/m·K, these pads provide excellent compressibility, ensuring low-pressure, tight contact for rapid heat transfer. Additionally, silicone thermal pads possess excellent electrical insulation properties, making them ideal for applications that require both thermal conductivity and electrical insulation, such as LED driver power supplies and circuit boards.

Unlike thermal grease, silicone thermal pads are easier to install and remove, making them suitable for LED modules that require maintenance or replacement. Their high flexibility and cuttable nature provide flexible thermal management solutions for components of various shapes and sizes, offering greater versatility in product design and manufacturing.

4. Integrated Bonding and Heat Dissipation Design

Nfion's thermal bonding solutions integrate thermal conductive adhesive, thermal grease, and silicone thermal pads, offering a comprehensive bonding and heat dissipation solution. This not only enhances heat dissipation but also ensures the mechanical strength and stability of LED components. The combination of thermal grease and silicone thermal pads allows for flexibility in addressing different installation environments and thermal management requirements, providing customers with more options.

5. Long-Lasting Reliability

Nfion's thermal conductive adhesive, thermal grease, and silicone thermal pads have undergone rigorous reliability testing, including high-temperature aging, thermal cycling, and humid heat environment tests. These materials maintain excellent heat dissipation and bonding performance even in extreme environments. Whether for outdoor lighting or industrial lighting applications, Nfion's thermal conductivity and heat dissipation bonding solutions ensure long-term reliability and stability for LED lights.

Advantages of Nfion’s Thermal Conductivity and Heat Dissipation Bonding Solutions

Nfion's thermal bonding solutions offer LED lighting companies several key advantages:

1. Extended Product Lifespan

By optimizing the thermal management system, Nfion’s thermal conductive adhesive, thermal grease, and silicone thermal pads effectively reduce heat resistance, lower operating temperatures, and extend LED lifespan, preventing heat damage and product failure.

2. Reduced Production Costs

Nfion's thermal bonding solutions simplify the production process by reducing the reliance on screws, clips, and other fasteners while enhancing assembly efficiency. The ease of application of thermal grease and silicone thermal pads also reduces the complexity of procedures, lowering labor costs and time investment.

3. Enhanced Product Performance

With superior thermal conductivity and reliability, Nfion's solutions ensure that LED luminaires maintain stable light output in complex environments. Whether in high-temperature or low-temperature conditions, Nfion's thermal materials deliver efficient heat dissipation, enhancing overall product performance.

4. Market Outlook and Development Trends

As smart lighting, automotive lighting, and outdoor lighting continue to evolve, the thermal management needs of LED luminaires are becoming increasingly diverse. Nfion's thermal bonding and heat dissipation solutions not only meet current market demands but also offer excellent scalability and customization capabilities. In the future, Nfion will continue to invest in innovation, launching even more efficient and reliable thermal conductive adhesive to drive sustainable development in the LED lighting industry.

Conclusion

Nfion’s LED lighting thermal conductivity and heat dissipation bonding solutions, through the integration of thermal conductive adhesive, thermal grease, and silicone thermal pads, offer high-efficiency heat dissipation, reliable bonding, and long-lasting thermal management. These solutions not only significantly enhance heat dissipation performance and extend product lifespan but also reduce production costs and improve market competitiveness. Nfion remains committed to driving innovation in thermal management technology, helping the LED lighting industry tackle future technical challenges.

CN >

CN >