In photovoltaic (PV) power systems, the inverter is the core component that connects solar modules to the grid. Its stability and efficiency directly determine the system's overall performance. As power density increases and system integration deepens, internal heat buildup in inverters has become a growing concern, significantly impacting their lifespan and reliability. Effective thermal management is now a critical aspect of PV inverter design and manufacturing.

Why Thermal Management Is Crucial for PV Inverters

During long-term operation, inverters generate significant heat, mainly from power devices (such as IGBTs and MOSFETs), magnetic components, and filter capacitors. Without timely heat dissipation, rising temperatures can lead to:

● Accelerated component aging and reduced reliability

● Decreased conversion efficiency and increased energy loss

● Higher failure rates and increased maintenance costs

Studies show that for every 10℃ increase in temperature, the lifespan of electronic components is halved. Establishing efficient and reliable thermal management systems is essential to enhancing the overall competitiveness of PV inverters.

Common Thermal Management Challenges in PV Inverters

1. Compact Space, High Dissipation Difficulty:

As power density increases, inverters are becoming smaller and more compact, making it harder to release accumulated heat.

2. Harsh Operating Environments:

PV stations are often installed outdoors in high-temperature, humid, and dusty environments, demanding higher weather resistance from thermal materials.

3. Uneven Heat Distribution and Local Hotspots:

Heat sources are concentrated, and improper thermal design can result in hotspots that compromise system stability.

Key Thermal Management Techniques and Material Applications

To address these challenges, modern thermal management strategies go beyond traditional air or water cooling systems, incorporating advanced thermal interface materials (TIMs) and structural optimization:

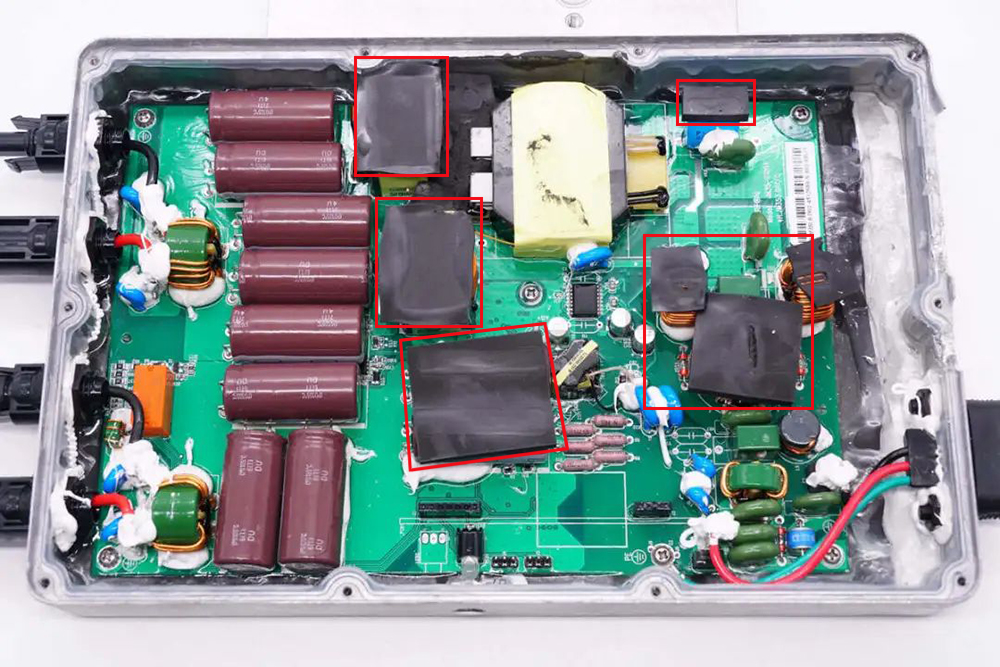

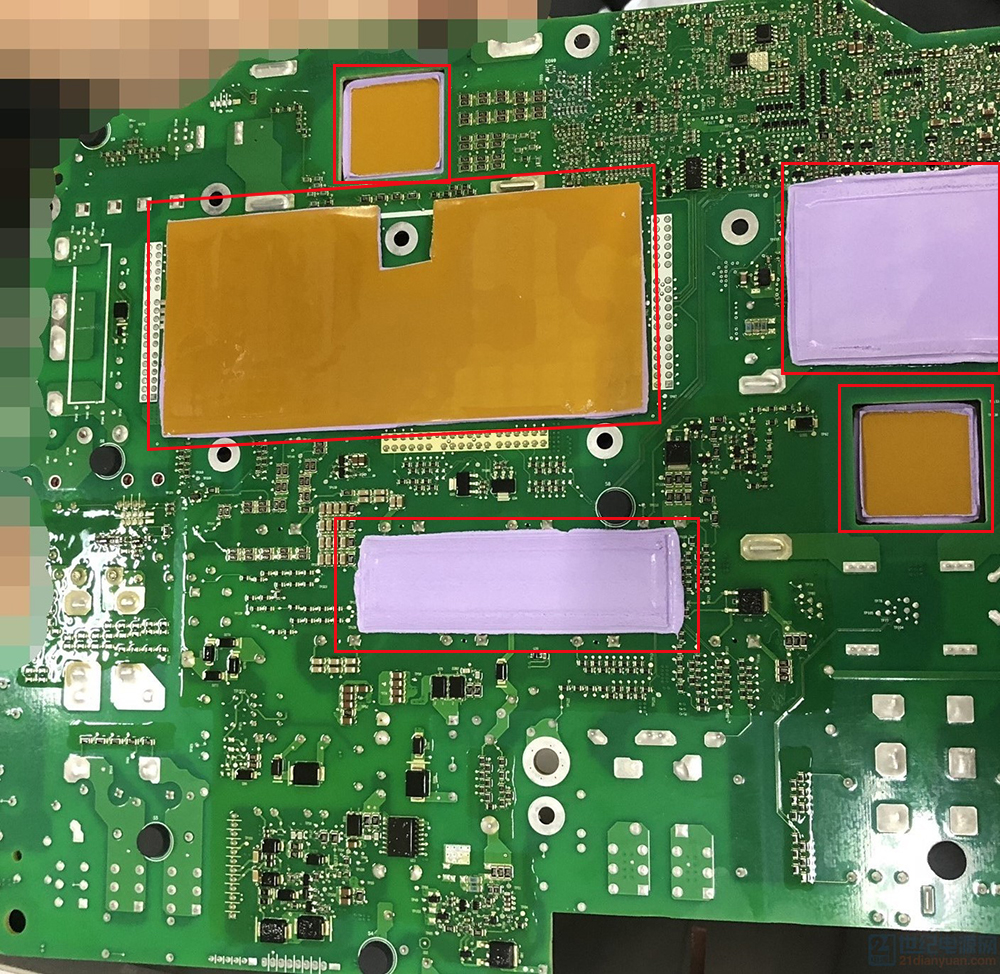

TIMs effectively fill the microscopic gaps between components and heat sinks, reducing thermal resistance and enhancing conductivity. Common types include:

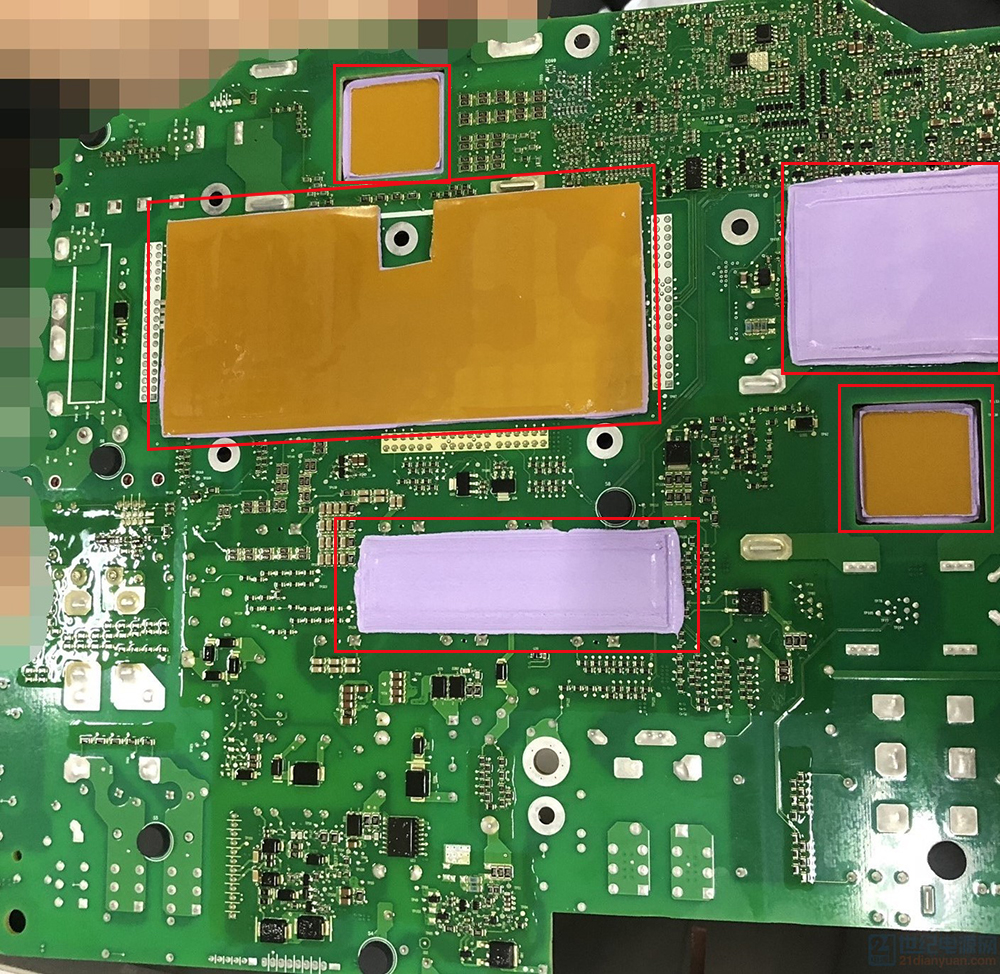

● Thermal Pads: Soft and compressible, ideal for gap-filling between components and heat sinks, offering good insulation and stability.

● Thermal Gel: Low-stress and flowable, suitable for high-power modules requiring premium heat dissipation.

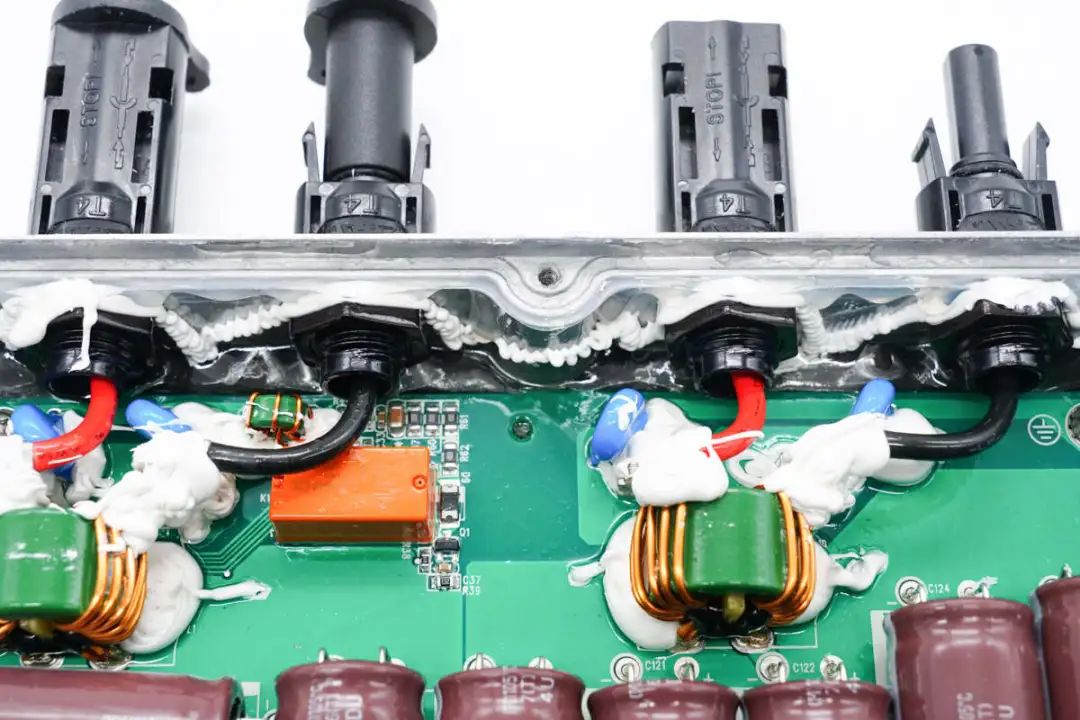

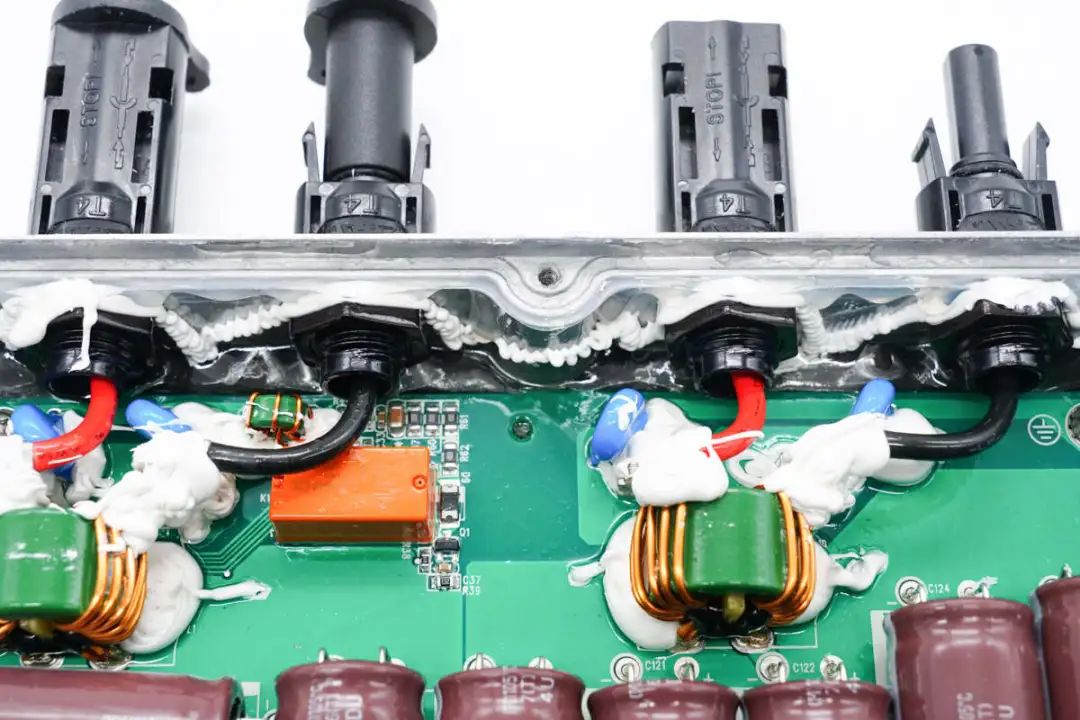

● Thermally Conductive Adhesives: Provide both bonding and thermal conduction, useful where structural fixation and thermal paths are both needed (e.g., between inductors and base plates or PCB and heat sinks).

● Thermal Potting Compounds: Used for encapsulating power modules or power supplies, offering moisture-proofing, vibration resistance, and improved durability.

2. Thermal Design Optimization

● Thermal Simulation and Layout Optimization:

CFD thermal simulation aids in pre-design, optimizing component layout and heat paths.

● Air Duct and Enclosure Design:

Airflow-guiding structures combined with efficient fans enhance convective heat transfer.

● Heat Sinks and Heat Pipes:

Aluminum heat sinks, vapor chambers, or heat pipes are widely used to quickly transfer and spread heat, especially for high-power heat sources.

NFION’s Thermal Material Solutions for PV Inverters

In the field of inverter thermal management, NFION offers a comprehensive and reliable portfolio of thermal materials tailored to diverse heat dissipation requirements—from gap-filling and adhesive bonding to potting protection:

● High-Performance Thermal Pads (1~12 W/m·K): Applied between power devices and heat sinks to reduce interface thermal resistance.

● Thermal Gels (1.5~10 W/m·K): Designed for high-density modules, offering excellent coverage over uneven surfaces.

● Thermal Adhesives (0.8~2 W/m·K): Combine mechanical bonding and thermal conduction to simplify assembly and improve reliability.

● High-Insulation Potting Compounds: Protect sensitive electronics against moisture and contaminants, enhancing long-term stability.

NFION’s materials are widely used in residential inverters, C&I storage inverters, and large-scale centralized systems, and have been validated and adopted by leading PV inverter manufacturers.

Conclusion: Thermal Management is Not a Supporting Role—It's the Core Technology

As the PV industry evolves toward higher power, integration, and intelligence, thermal management has shifted from a secondary concern to a core design element—a key differentiator in inverter performance. Selecting high-reliability thermal materials and optimizing thermal structure design are essential paths to higher efficiency and long-term durability.

Good thermal management doesn't just reduce temperatures—it boosts efficiency and extends lifespan.

If you're seeking advanced thermal management solutions for your PV inverters, contact NFION to explore the future of reliable heat dissipation.

CN >

CN >