With the rapid development of intelligent security technologies, surveillance equipment has been widely used in smart cities, industrial parks, traffic management, and home security. These devices generate significant amounts of heat during prolonged operation, and if not managed effectively, this can lead to performance degradation, shortened service life, and even equipment failure. Therefore, advanced thermal management technologies and materials are essential to ensure the reliability and safety of security surveillance equipment.

Leveraging years of technical expertise and innovation in the field of thermal management materials, NFION has introduced a thermal management solution tailored to security surveillance equipment. This solution aims to enhance heat dissipation and stability, ensuring efficient operation in various challenging environments. This article delves into NFION's thermal management solution and its significance for security surveillance equipment.

The Critical Role of Thermal Management in Security Surveillance Equipment

Modern security surveillance equipment, such as cameras, recorders, and network video servers, integrates high-performance processors, sensors, and communication modules. These components generate a significant amount of heat during long-term high-load operation. If this heat is not effectively dissipated, it can lead to a range of issues:

1. Performance Degradation: Excessive heat can slow down processing speeds and response times, especially for image processing and data transmission modules. Heat buildup directly affects the image quality and reliability of information transfer in surveillance equipment.

2. Component Damage: Prolonged exposure to high temperatures accelerates the aging of electronic components, increasing the risk of equipment failure and reducing its lifespan.

3. System Shutdown or Data Loss: In some cases, overheating may cause sudden system shutdowns, leading to data loss or blind spots in surveillance coverage, directly threatening the stability and safety of the security system.

Therefore, a robust thermal management system is essential for ensuring the performance, long-term stability, and safety of security surveillance equipment. NFION understands these industry needs and has developed a range of thermal management materials designed to provide comprehensive heat dissipation support.

Core Technologies in NFION's Thermal Management Materials

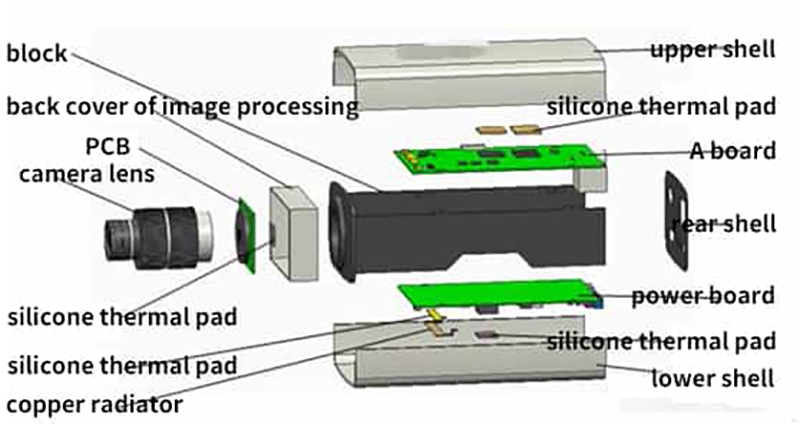

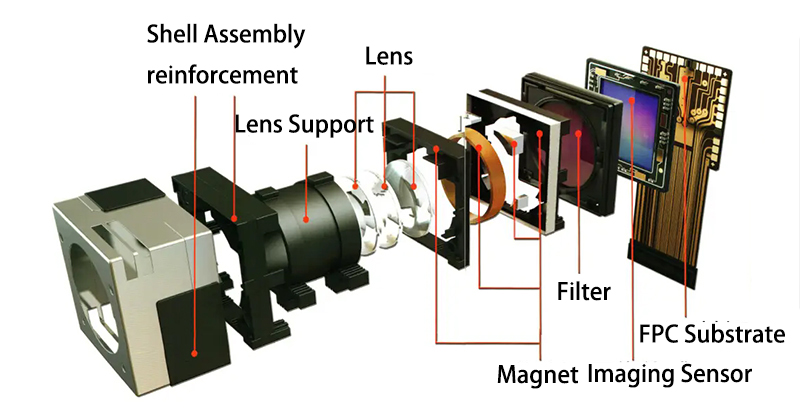

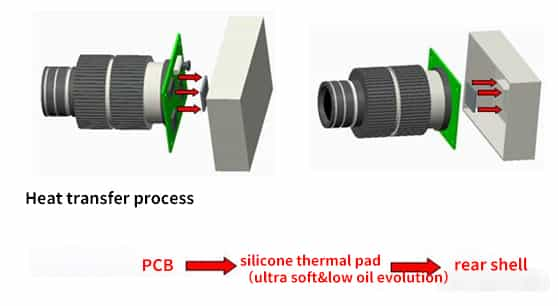

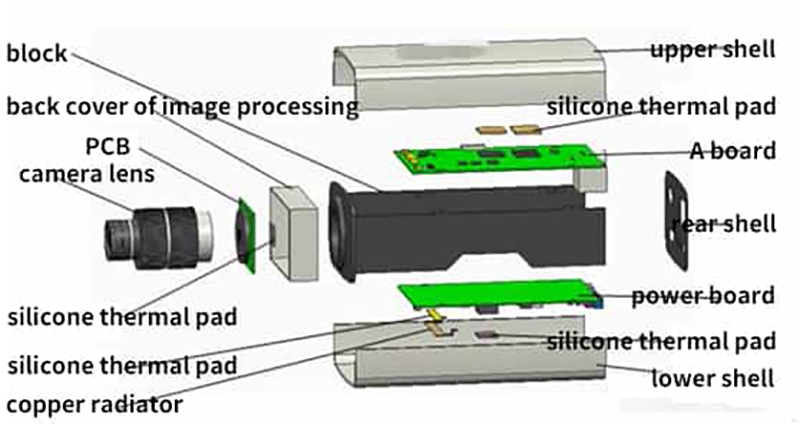

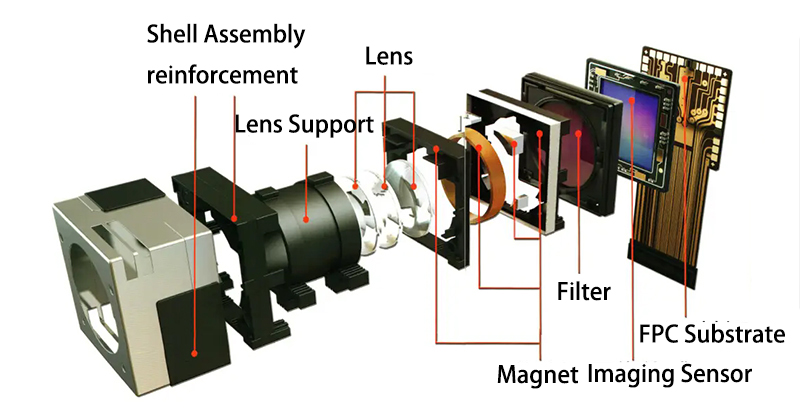

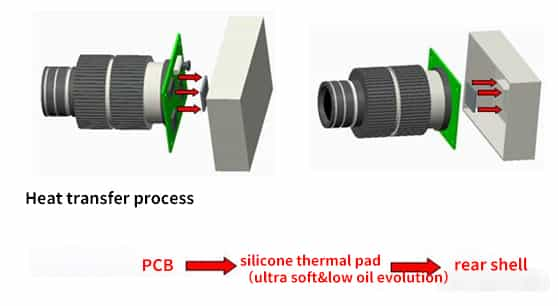

NFION’s thermal management solutions for security surveillance equipment rely on high-performance thermal materials, including sil pads, thermal gels, thermal grease, thermal graphite sheets, and shielding materials. These materials demonstrate excellent heat dissipation, durability, and adaptability to various environments.

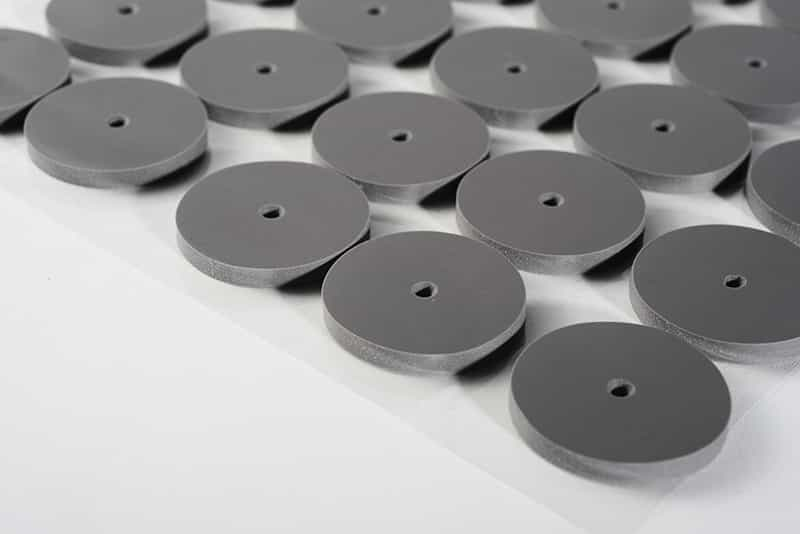

Sil pads are a key material in NFION's solution, offering high thermal conductivity and excellent compressibility. They provide a stable thermal path between heat-generating components and heat sinks, filling microscopic gaps in the equipment and ensuring uniform heat dissipation. Additionally, sil pads have good electrical insulation properties, making them suitable for the thermal management of sensitive electronic components in cameras and recording devices.

2. Thermal Gels

Thermal gels are highly flexible, low-viscosity thermal materials that can easily fill complex and irregular gaps, forming a stable thermal path. Unlike sil pads, thermal gels are softer and easier to apply, making them ideal for applications requiring high compressibility. They offer efficient thermal performance and adjust to the operational states of equipment to ensure continuous contact and maximize heat dissipation.

3. Thermal Grease

Thermal grease is a highly viscous thermal interface material widely used for high-performance thermal management. It has extremely low thermal resistance, enabling fast and effective heat transfer. Thermal grease is commonly applied between processors and heat sinks to ensure rapid heat transmission to cooling devices. It also has excellent high-temperature resistance, making it suitable for high-power-density devices, providing consistent and efficient heat conduction.

4. Thermal Graphite Sheets

These materials offer high thermal conductivity in the planar direction, quickly spreading heat across a larger surface area. They are ideal for dissipating heat from high-density components such as microprocessors and chips in security surveillance equipment. The thin, flexible nature of thermal graphite sheets makes them especially suitable for compact devices where space and weight are critical.

5. Shielding Materials

In addition to thermal properties, NFION’s shielding materials effectively block electromagnetic interference (EMI), ensuring that the equipment is not affected by external electromagnetic waves during high-frequency signal transmission. This is crucial for maintaining signal stability and image quality in security devices.

Significant Advantages of NFION’s Thermal Management Solutions

NFION’s thermal management solutions for security surveillance equipment not only feature advanced technology but are also optimized for real-world applications, offering the following significant advantages:

1. Efficient Heat Dissipation for Equipment Stability

NFION’s thermal materials efficiently transfer heat from internal components to external heat sinks or enclosures, ensuring that equipment remains within safe temperature limits during prolonged operation, preventing performance degradation due to overheating.

2. Excellent Environmental Adaptability

Security surveillance equipment is often exposed to harsh outdoor environments, facing challenges such as extreme temperatures, humidity, dust, and more. NFION’s thermal materials are highly weather-resistant and durable, maintaining excellent heat dissipation performance in extreme conditions, making them suitable for various outdoor and industrial applications.

3. Reduced Maintenance Costs

Effective thermal management reduces equipment failure rates and maintenance frequency, extending the service life of devices and lowering long-term maintenance costs for customers. This is especially important for surveillance systems that require continuous operation.

4. Environmental Protection and Sustainability

NFION’s thermal materials adhere to strict environmental standards during production, using non-toxic and harmless raw materials to minimize environmental impact. Additionally, the long lifespan and stability of the materials reduce the need for frequent replacement, further conserving resources.

Case Studies

NFION's thermal management solutions have been successfully applied in several security surveillance projects, covering smart cities, traffic management, industrial park surveillance, and more. For example, in a city’s intelligent traffic monitoring project, NFION's sil pads effectively resolved heat dissipation issues in high-temperature environments, significantly improving the cameras' image processing capabilities and response speeds. In another large industrial park’s surveillance system, the application of thermal graphite sheets helped the equipment maintain stable operation, avoiding shutdowns and blind spots caused by overheating.

Conclusion

As security surveillance equipment becomes increasingly vital in daily life, thermal management challenges are becoming key issues in the industry. NFION’s thermal management solutions for security surveillance equipment offer highly efficient thermal performance and broad applicability, effectively enhancing the operational stability and lifespan of the devices.

In the future, NFION will continue to focus on innovation and optimization in thermal management technology, providing customers with superior material solutions and contributing to the sustainable development of the security industry.

CN >

CN >