With the rapid development of advanced technologies such as 5G, the Internet of Things (IoT), and cloud computing, the performance demands on network communication equipment have significantly increased. The need for higher transmission speeds and greater data processing capacity has presented severe challenges for heat management in network devices. If the heat generated during high-performance operations is not effectively managed, it can lead to system instability, reduced service life, or even damage to core components. To address these challenges, Thermal Interface Materials (TIMs) have become a crucial element for managing heat in network communication devices. As a leading company in the thermal materials industry, NFION’s thermal interface materials provide efficient thermal management solutions for the network communication sector.

1. Increasing Power Density

3. Need for Continuous and Stable Operation

Thermal silicone pads (Sil Pad) are soft and flexible thermal materials designed to fill irregular gaps between electronic components, providing efficient heat conduction:

- High Thermal Conductivity: NFION’s thermal silicone pads have a thermal conductivity of up to 6.0 W/m·K, quickly transferring heat to heat sinks and reducing the risk of overheating.

- Flexibility and Compressibility: Their soft nature allows them to adapt to various uneven surfaces while minimizing mechanical stress, avoiding damage to components.

- Long-term Durability: These materials maintain excellent performance in high-temperature environments, making them suitable for long-term operational devices.

Thermal gels are highly flowable, easy-to-apply materials particularly suitable for components requiring high-precision cooling, such as high-density integrated circuits:

- Low Thermal Resistance: Thermal gels achieve extremely low thermal resistance at low pressure, ensuring efficient heat conduction for core components.

- High Flexibility: They can be applied automatically or manually, adapting to the installation requirements of complex equipment.

- Excellent Environmental Adaptability: Thermal gels remain stable over time, regardless of high temperatures or harsh environments, reducing the risk of thermal aging and hardening.

Thermal grease is used in high heat-density components (such as between CPUs and heat sinks), effectively filling micro gaps to ensure optimal thermal contact:

- Low Thermal Resistance: Even at low pressure, thermal grease achieves efficient heat conduction, improving component heat dissipation.

- Wide Temperature Range: It performs well across a wide range of temperatures, maintaining excellent thermal management in high-temperature environments.

- Easy Application: It can be evenly applied to various irregular surfaces, ensuring close contact between heat sinks and components.

Thermal adhesive combines thermal conductivity and mechanical bonding, suitable for permanently attaching heat sinks or components:

- High Bonding Strength: It provides strong bonding while maintaining good thermal conductivity, ensuring the firm attachment of heat-dissipating parts.

- High-Temperature Resistance and Anti-Aging: The adhesive withstands high temperatures and complex working conditions, preventing equipment aging or failure.

- Versatile Application: Thermal adhesive offers additional structural stability in high-vibration environments, such as base station antenna modules.

Thermal potting compounds are used to encapsulate and protect electronic components, providing waterproofing, dustproofing, and anti-corrosion protection while maintaining high thermal conductivity:

- Comprehensive Protection: The compound fully encapsulates components, shielding them from external environmental impacts.

- High Thermal Conductivity: Despite encapsulation, it effectively dissipates heat generated by the equipment.

- Electrical Insulation: It prevents electrical faults like short circuits and ensures the safe operation of the equipment.

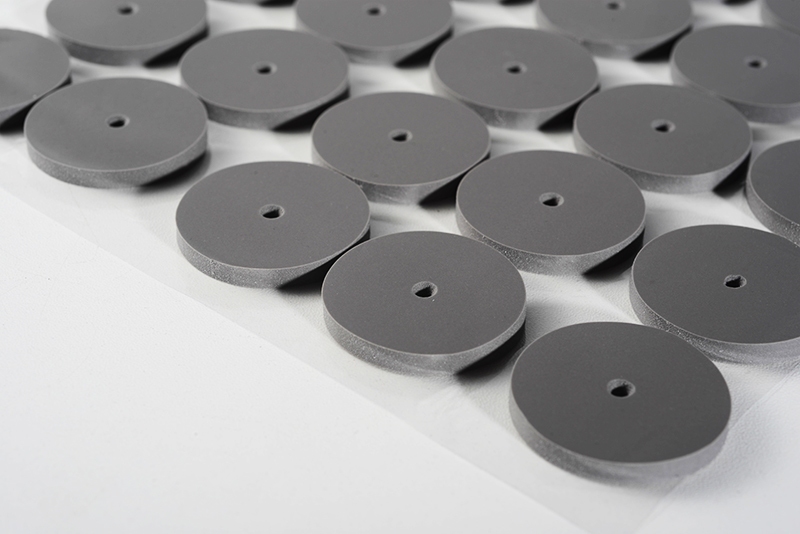

Thermal insulation pads combine both thermal conductivity and electrical insulation, making them ideal for applications requiring high thermal conductivity and electrical insulation, such as high-voltage power modules:

- Combining High Thermal Conductivity and Insulation: These pads transfer heat while preventing current leakage, ideal for critical equipment requiring insulation.

- Mechanical Strength and Durability: They resist wear and tear, suitable for long-term use in complex environments.

Phase change materials (PCM) change from solid to liquid when exposed to heat, absorbing a large amount of heat during the phase transition, thereby improving thermal management efficiency:

- High Heat Capacity: During the phase change process, PCM absorbs a large amount of heat, reducing the working temperature of components.

- Auto-Filling Gaps: When changing phase, the material flows into gaps between components, achieving seamless thermal conduction.

1. 5G Base Stations

2. Data Center Servers

3. Optical Communication Devices

CN >

CN >