As modern electronic devices continue to evolve toward higher efficiency and performance, thermal management technology has become increasingly critical in many industries, especially in beauty tools. As a core component of these tools, hair straighteners not only require excellent heating performance but must also ensure safety and comfort during use. Excessive heat can lead to overheating, affecting both performance and product lifespan. Thus, effectively managing and dissipating heat within the device is key to improving product quality and user experience.

NFION, as a leading manufacturer of thermal interface pads, is committed to providing efficient and stable thermal management solutions, helping various electronic devices enhance performance and extend service life. NFION focuses on the application of thermal interface pads in hair straighteners, analyzes their features and technical advantages, and offers feasible thermal management solutions for manufacturers.

Challenges of Thermal Management in Hair Straighteners

Hair straighteners work by converting electrical energy into heat through a heating plate, which is then transferred to the hair. During this process, the heating plate generates substantial heat, which can accumulate inside the device if not properly managed. Without an efficient thermal management system, heat buildup can lead to overheating, damaging internal circuits or compromising user safety.

High Temperatures Affect Performance and Safety

The heating element in a hair straightener heats up rapidly. However, without an effective cooling system, high temperatures can cause several issues:

● Component Damage Due to Overheating: Prolonged exposure to excessive heat accelerates the aging of components, reducing the device's lifespan.

● User Safety Risks: High temperatures can overheat the housing, increasing the risk of burns during use.

The Need for Effective Heat Conduction and Dissipation

Hair straighteners require a high-performance thermal management solution to transfer and dissipate heat effectively, preventing overheating. Designers must select high thermal conductivity materials to efficiently transfer internal heat to the exterior, ensuring the device’s safety and stability.

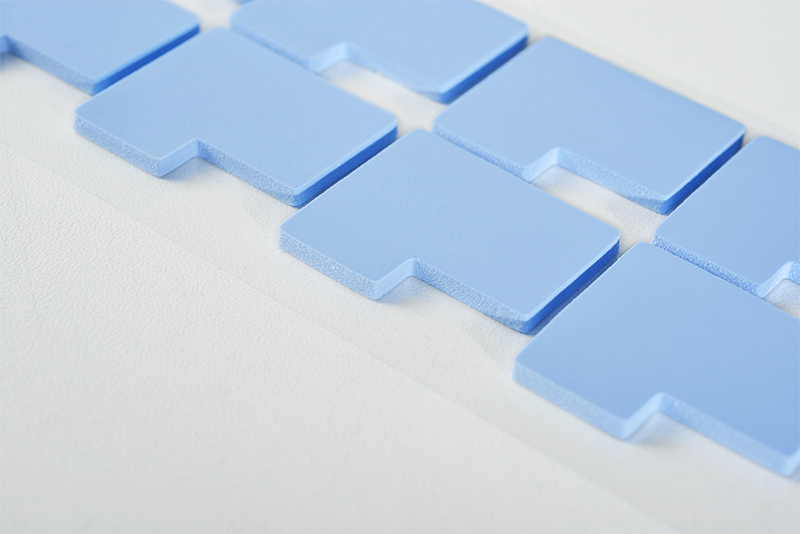

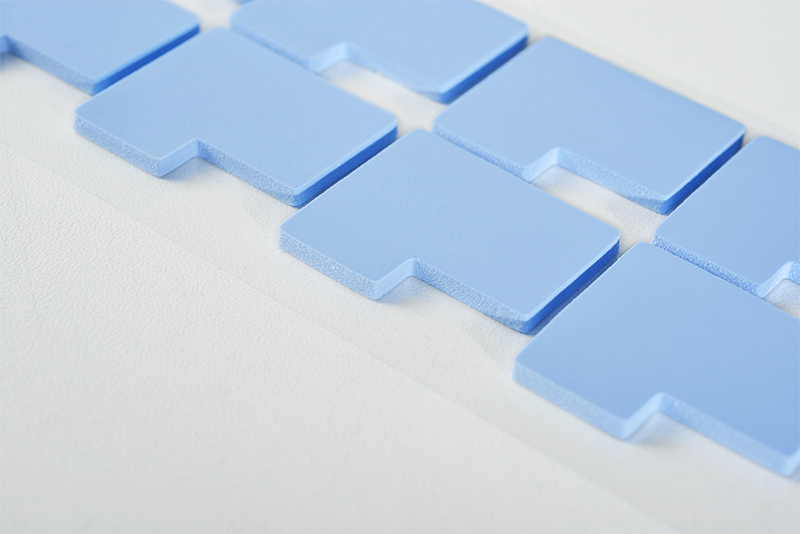

NFION thermal interface pads excel in thermal management, offering significant technical advantages. As an advanced thermal conductive material, thermal interface pads possess the following features, making them ideal for high-temperature and high-power electronic products:

High Thermal Conductivity

Manufactured using high-quality thermal fillers and silicone bases, NFION thermal interface pads have superior thermal conductivity. They rapidly transfer heat generated inside the hair straightener, maintaining internal temperatures within a safe range. This feature allows the device to reach the desired temperature faster while reducing heat accumulation and avoiding overheating.

Excellent Electrical Insulation

Electrical insulation is crucial in hair straightener design. Thermal interface pads not only deliver superior thermal conductivity but also provide excellent electrical insulation, effectively preventing short circuits or current leakage between components, adding an extra layer of safety.

High-Temperature Resistance

Hair straighteners operate at high temperatures, making thermal interface pads’ heat resistance essential. NFION pads maintain stable performance under extreme heat, ensuring consistent thermal conductivity and mechanical properties, which prolongs the device’s lifespan.

Enhanced Flexibility and Adaptability

With excellent flexibility, NFION thermal interface pads can adapt to various shapes and sizes of heating elements, ensuring tight contact and optimal thermal transfer. Whether on complex heating plate structures or tightly fitted designs, these pads deliver reliable performance.

Long-Term Stability

With high chemical stability and environmental resistance, NFION thermal interface pads withstand prolonged exposure to high temperatures and humidity without degradation. This durability ensures reliable performance throughout the product’s life cycle.

Application of NFION Thermal Interface Pads in Hair Straighteners

Installation Locations

In hair straighteners, thermal interface pads are typically placed between the heating plate and the housing, circuit boards, or other heat-sensitive components. Their primary function is to establish an efficient thermal conduction channel, rapidly transferring heat to prevent overheating.

● Between the Heating Plate and Housing: The pads effectively transfer heat from the heating plate to the housing, enabling efficient heat dissipation and preventing excessive heat buildup.

● Between Circuit Boards and Heating Elements: They protect circuit boards from direct heat generated by the heating element, reducing the risk of electrical damage.

Solution Example

● Using Heat Sinks: When combined with heat sinks, thermal interface pads enhance heat dissipation efficiency. The pads channel heat to the sinks, which then disperse it through increased surface area.

● Optimized Structural Design: Designers can leverage the pads’ properties to optimize internal layouts, ensuring rapid heat transfer from heating elements to the housing, avoiding localized overheating.

Conclusion and Outlook

As consumer demands for the performance and safety of beauty tools increase, manufacturers must consider thermal management in their designs. NFION thermal interface pads offer an efficient, reliable solution with exceptional thermal conductivity, electrical insulation, and heat resistance. By selecting the right materials and adopting innovative designs, hair straighteners can achieve faster heating, more stable performance, and longer lifespans.

Looking ahead, NFION remains dedicated to providing more efficient and eco-friendly thermal management solutions to meet the complex thermal challenges of modern electronic products, supporting the development of high-quality devices worldwide.

CN >

CN >