In fields such as precision electronics and aerospace, thermal management in a vacuum environment has always been a severe challenge for engineers. Among them, silicone thermal pads, as a crucial thermal interface material, have raised concerns about their applicability in vacuum conditions. So, can silicone thermal pads work safely and effectively in a vacuum environment? This article will delve into this core question.

Special Requirements of Vacuum Environment on Materials

Before answering whether silicone thermal pads are suitable for vacuum environments, we first need to understand the special requirements that vacuum conditions impose on materials. A vacuum state means extremely low pressure, which significantly affects a material's outgassing, thermal conductivity, and mechanical stability.

1. Outgassing: In a vacuum, volatile substances (such as plasticizers, residual solvents, etc.) within the material will gradually escape, forming gases. This not only can contaminate the vacuum system and reduce its vacuum level but also may condense on the surface of precision optical devices or sensors, affecting equipment performance. Therefore, materials used in a vacuum environment must have extremely low outgassing properties.

2. Stability of Thermal Conductivity: The material's thermal conductivity needs to remain stable under extreme pressure. If the material itself undergoes physical or chemical changes due to the vacuum, its thermal transfer efficiency will be greatly reduced.

3. Mechanical Stability: In a vacuum environment, some materials might expand, contract, or become brittle, affecting their original mechanical properties and their contact effectiveness with devices.

Performance of Silicone Thermal Pads in a Vacuum Environment

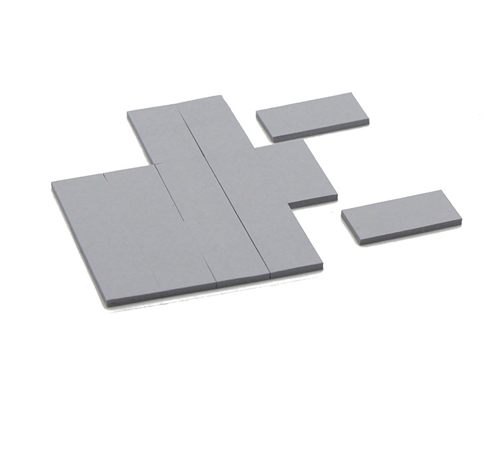

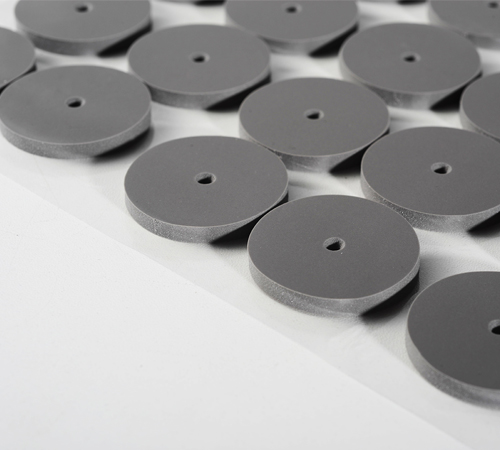

Silicone thermal pads are primarily composed of a silicone rubber matrix and thermal fillers (such as aluminum oxide, boron nitride, etc.). Their applicability in a vacuum environment depends on their formulation and manufacturing process.

1. Outgassing: The Crucial Consideration

Traditional silicone thermal pads, especially those containing more low-molecular-weight silicone oil or other volatile additives, indeed have a high outgassing problem in a vacuum environment. These volatiles can lead to:

▪ Vacuum Contamination: Affecting the operational stability of vacuum equipment and even increasing the pump load.

▪ Device Contamination: Volatiles condensing on cold surfaces form a thin film, affecting the light transmittance of optical components, the reliability of electrical contacts, and even causing short circuits.

However, with advancements in material science, many low outgassing or ultra-low outgassing silicone thermal pads have been introduced. These products achieve low outgassing through:

▪ Optimized Silicone Rubber Formulation: Using higher molecular weight, more cross-linked silicone rubber to reduce the content of small molecules.

▪ Selected Thermal Fillers: Choosing surface-treated thermal particles without volatile impurities.

▪ Special Manufacturing Processes: Such as high-temperature baking or vacuum processing during production to further remove volatile substances.

These low outgassing silicone thermal pads typically meet the requirements of the NASA ASTM E595 standard (Total Mass Loss TML < 1.0%, Collected Volatile Condensable Material CVCM < 0.1%), indicating a low risk of contamination in a vacuum environment.

2. Thermal Conductivity and Mechanical Stability

For qualified low outgassing silicone thermal pads, their silicone rubber matrix and thermal fillers generally maintain stable thermal conductivity in a vacuum. Silicone rubber itself does not undergo significant physical phase transitions or decomposition in a vacuum, so its stability as a base material is good.

Furthermore, silicone thermal pads usually have a certain degree of flexibility and compressibility, which allows them to effectively fill the tiny gaps between the heat source and the heat sink in a vacuum, maintaining good thermal contact and ensuring efficient heat transfer. Their mechanical properties (such as hardness, tensile strength, etc.) are also relatively stable in a vacuum environment, without significant degradation, thus ensuring long-term reliability.

Conclusion and Application Recommendations

In conclusion, silicone thermal pads can be used in a vacuum environment, but not all products are suitable.

Core Point: Choosing dedicated silicone thermal pads certified for low outgassing (e.g., NASA ASTM E595) is key to ensuring their stable and reliable application in a vacuum environment.

When selecting a silicone thermal pad for a vacuum environment, be sure to pay attention to the following points:

▪ Check the Product Datasheet: Confirm whether the product is explicitly labeled "Low Outgassing" or complies with relevant vacuum application standards.

▪ Request Test Reports from the Supplier: Especially the ASTM E595 test report, to verify its outgassing indicators.

▪ Consider the Specific Application Scenario: Different vacuum level requirements (high vacuum, ultra-high vacuum) and operating temperature ranges may impose higher demands on the performance of the silicone thermal pad.

By selecting appropriate low outgassing silicone thermal pads, engineers can effectively solve thermal management challenges in a vacuum environment, ensuring the stable operation and long lifespan of precision equipment under extreme conditions. When you choose silicone thermal pads, do you pay special attention to their outgassing indicators?

CN >

CN >