Have you ever wondered how complex and delicate chips avoid overheating during the manufacturing process? In modern electronics, especially in the semiconductor and data center industries, temperature control is crucial for ensuring device performance and stability. Behind this, a special medium known as fluorinated fluid plays a vital role. With its unique physical and chemical properties, it has become the ideal choice for precision cooling and cleaning of electronic devices.

What is Fluorinated Fluid?

Fluorinated fluid, also known as perfluoropolyether (PFPE), is a class of compounds composed entirely of carbon (C), fluorine (F), and oxygen (O) atoms. Unlike traditional coolants, its core advantage lies in its molecular structure where all hydrogen atoms have been replaced by fluorine atoms. This structure gives it a series of unique properties:

▪ Excellent Electrical Insulation: Fluorinated fluids have extremely high electrical resistance, making them virtually non-conductive. This means they can come into direct contact with electronic components without the risk of short circuits or leaks.

▪ Outstanding Chemical Inertness: They do not react with most materials, including metals, plastics, and elastomers. This ensures compatibility with a wide range of precision devices, preventing corrosion or damage to sensitive components.

▪ Low Surface Tension: Fluorinated fluids can easily penetrate tiny gaps and pores, enabling efficient heat transfer. They also evaporate easily after cleaning, leaving no residue.

▪ Wide Operating Temperature Range: Fluorinated fluids typically remain stable within a temperature range of -40°C to 150°C and even higher, making them suitable for various demanding working environments.

The Role and Applications of Fluorinated Fluid

The unique properties of fluorinated fluid make it indispensable in several high-tech fields:

1. Precision Cooling: The Core of Liquid Cooling Technology

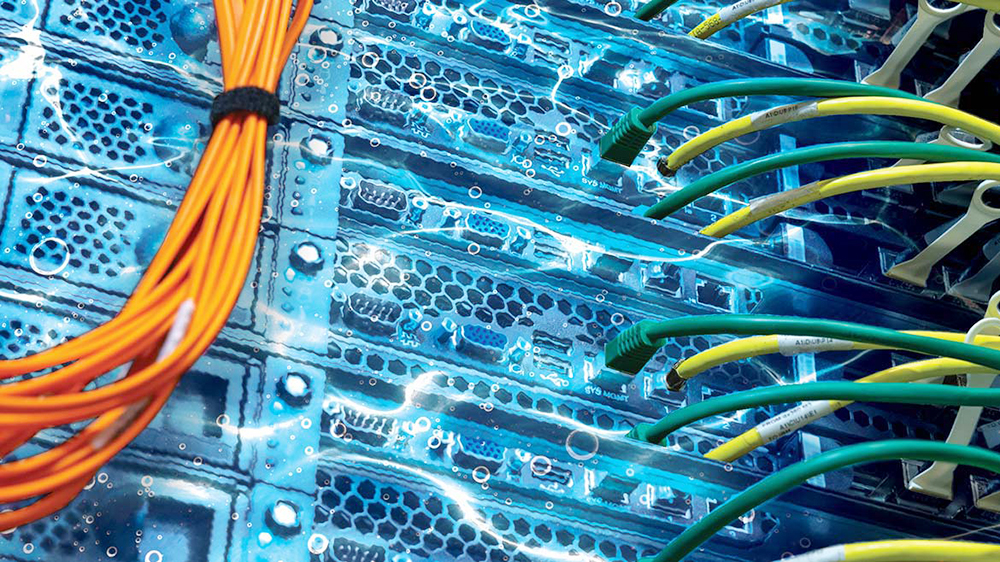

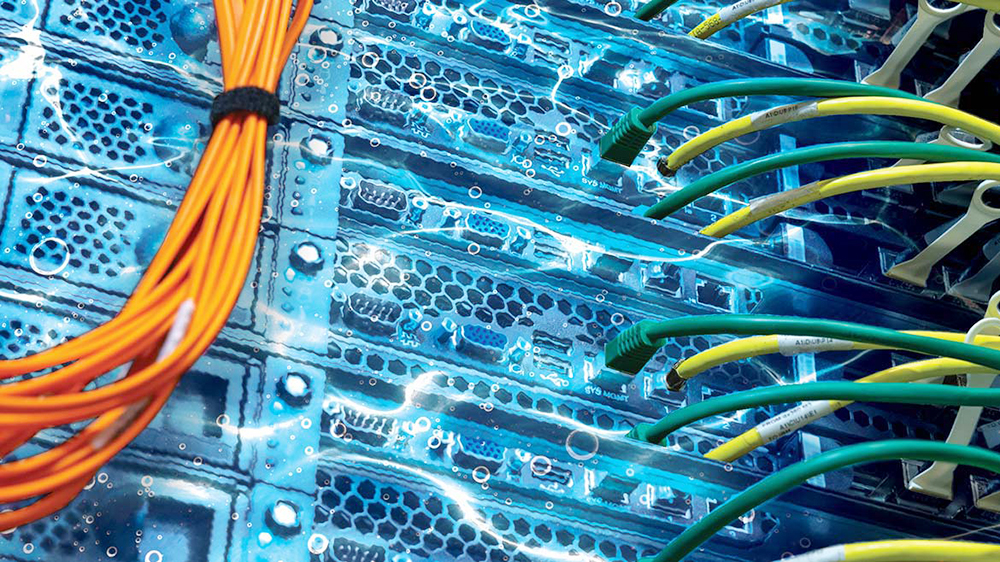

In high-heat-density fields such as semiconductor manufacturing, supercomputers, and data centers, traditional air cooling is often insufficient. As an ideal dielectric coolant, fluorinated fluid can directly immerse or circulate through pipes in contact with heat-generating components to achieve efficient liquid cooling.

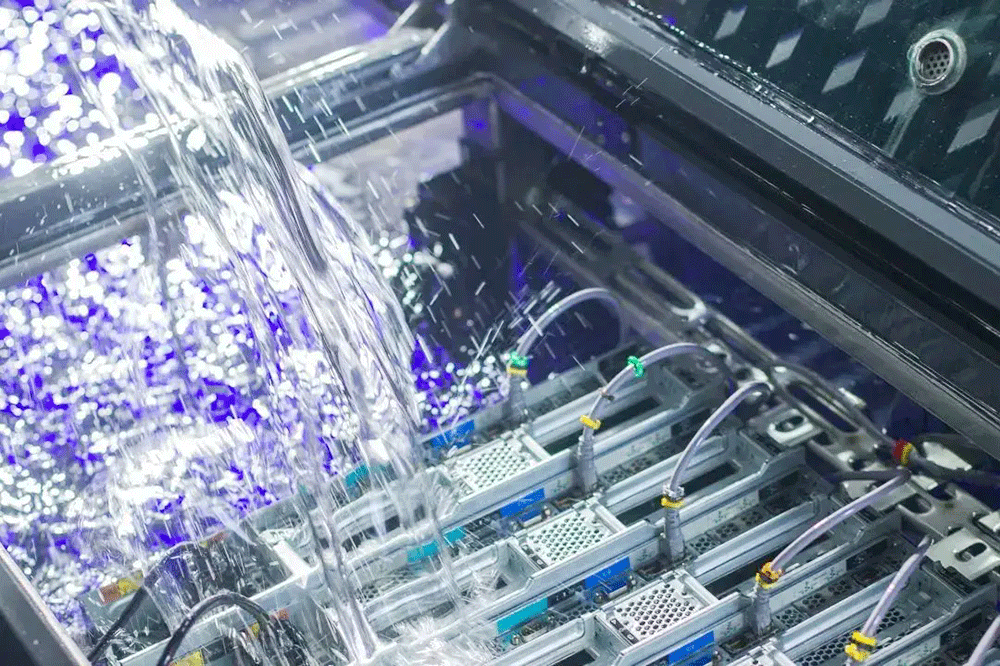

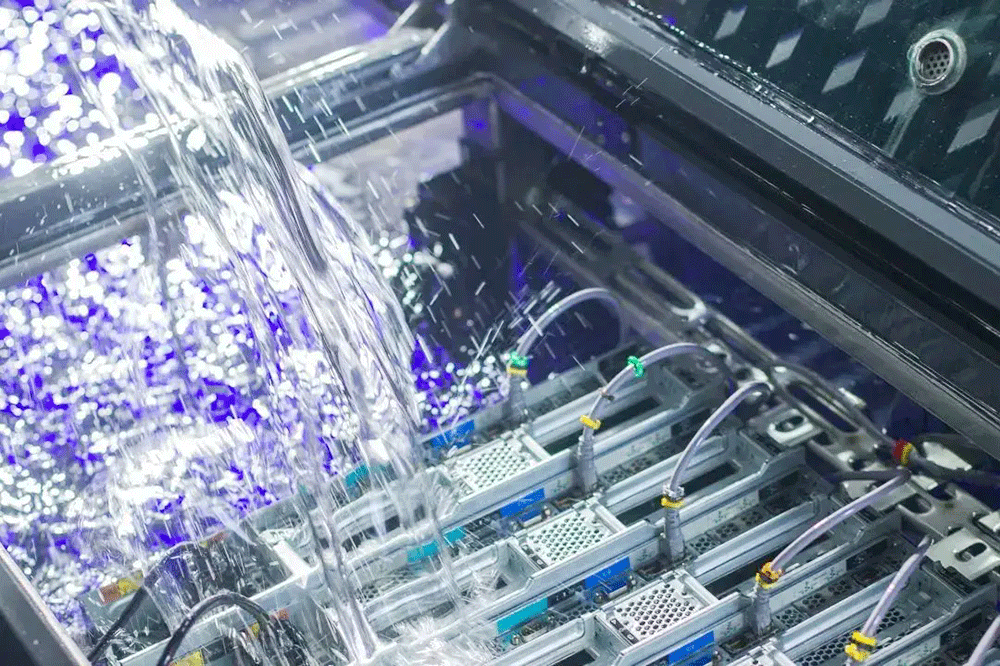

▪ Immersion Cooling: Heat-generating components like chips, CPUs, and GPUs are directly submerged in the fluorinated fluid. Since the fluid's specific heat capacity and thermal conductivity are much higher than air's, heat is rapidly dissipated, significantly lowering device temperature and improving performance and stability.

▪ Single-Phase Immersion Cooling: In this mode, the fluorinated fluid remains in a liquid state. Heat is transferred from the hot components to the liquid via convection. A pump then circulates the heated liquid to an external heat exchanger for cooling. This is a simple and efficient cooling method.

▪ Two-Phase Immersion Cooling: This is an even more efficient cooling method. Fluorinated fluids typically have a low boiling point. When the fluid comes into contact with a hot component, it absorbs heat and rapidly vaporizes (boils), changing from a liquid to a gas. This phase change process carries away a large amount of latent heat of vaporization, achieving extremely high heat dissipation efficiency. The vaporized fluid rises to the top of the cooling system, where it is condensed back into a liquid by a condenser, and then drips back into the fluid bath, completing the cycle.

2. Precision Cleaning: "Residue-Free" Cleaning for Electronic Components

In the electronic manufacturing process, cleaning is a critical step to remove residues like solder flux, grease, and particulate matter. Fluorinated fluid's low surface tension and chemical inertness make it an ideal precision cleaning agent:

▪ No Damage to Components: It is non-corrosive to sensitive electronic components, optical lenses, and precision instruments, ensuring a safe and damage-free cleaning process.

▪ No Residue: Because it evaporates easily without leaving a trace, cleaning with fluorinated fluid eliminates the need for an additional drying step, significantly simplifying the production process.

3. Lubrication and Sealing: Protecting High-Precision Equipment

In addition to cooling and cleaning, some variants of fluorinated fluid are also used as high-performance lubricants and sealing fluids.

▪ Vacuum Pump Oil: In high-vacuum environments, traditional oils can vaporize, affecting the vacuum level. The low vapor pressure of fluorinated fluid makes it an ideal oil for high-vacuum pumps.

▪ Sealing: In applications with extremely high demands for cleanliness and sealing, such as semiconductor equipment and medical devices, fluorinated fluids are used as sealing fluids or lubricants for seals to prevent contamination and leakage.

Advantages and Limitations

Advantages:

▪ Superior Performance: Fluorinated fluids excel in thermal conductivity, electrical insulation, and chemical inertness, making them superior to traditional cooling media.

▪ Environmental Friendliness: Some fluorinated fluids have a zero ozone depletion potential (ODP), posing no harm to the ozone layer and complying with environmental regulations.

▪ High Safety: They are typically non-flammable and non-toxic, offering a high level of safety during use and storage.

Limitations:

▪ High Cost: Compared to traditional coolants or cleaning agents, the manufacturing and recycling costs of fluorinated fluids are high, which is a major obstacle to their widespread adoption.

▪ Evaporation Loss: While easy evaporation is an advantage for cleaning, it can lead to losses in cooling systems, requiring additional maintenance and replenishment.

▪ Complex Recycling: The recycling and reuse of fluorinated fluids require specialized equipment and technology, increasing the cost and barrier to entry.

Future Development Trends

With the advancement of technologies like AI, 5G, and the IoT, the demand for computing power and thermal efficiency will continue to rise. As an efficient and safe solution, the application prospects for fluorinated fluid are becoming increasingly broad.

▪ Cost Optimization: In the future, with technological advancements and economies of scale, the manufacturing cost of fluorinated fluid is expected to decrease. This will enable its use in more fields, especially in cost-sensitive industries.

▪ Recycling Technology: As the use of fluorinated fluids increases, their recycling has become a crucial issue. Future recycling technologies will be more efficient and environmentally friendly, for example:

▪ Solvent Extraction and Distillation: Utilizing a precisely controlled distillation process to separate fluorinated fluid from contaminants and restore its purity.

▪ Membrane Separation Technology: Using special polymer membranes to filter and purify waste fluids, enabling the reuse of fluorinated fluid.

▪ Development of New Biodegradable Fluorinated Fluids: Research and development of fluorinated fluids that can decompose or degrade under specific conditions to reduce their environmental impact.

▪ New Formula Development: Developing new fluorinated fluid formulas with specific properties (e.g., lower boiling points or higher thermal conductivity) to meet the growing demand for precision cooling.

Conclusion

From the busy cooling systems on a semiconductor production line to the silent servers running in a data center, fluorinated fluid, with its unique properties, provides a solid and reliable guarantee for modern high-tech industries. It is not merely a chemical substance, but a silent hero driving the continuous progress of the electronics industry.

CN >

CN >