How Fast Should Thermal Gel Be Extruded? In-Depth Analysis and Practical Guide

In the realm of electronics thermal management, thermal gel has become an indispensable material due to its excellent gap-filling capabilities and high thermal conductivity. However, simply choosing a good thermal gel isn't enough; the appropriate extrusion rate is crucial for its performance to be fully realized. So, what exactly is the "right" extrusion rate? This isn't a simple fixed number; it involves considering multiple dimensions such as material properties, application equipment, and cooling requirements. This article will delve into the mysteries of thermal gel extrusion rates, providing you with professional and practical guidance.

Why Is Extrusion Rate So Important?

The extrusion rate directly impacts the uniformity of coverage, consistency of thickness, and ultimately, the cooling performance of the thermal gel. Both excessively fast and excessively slow extrusion rates can lead to problems:

▪ Extrusion Rate Too Fast: Can lead to material buildup, overflow, and the formation of air bubbles or voids, reducing contact area and thereby diminishing thermal conductivity. It also results in material waste and increased production costs.

▪ Extrusion Rate Too Slow: Can result in discontinuous coverage, insufficient thickness, or even breaks in the coating during application, preventing effective gap filling and similarly affecting thermal efficiency. Furthermore, it lowers production efficiency and extends production cycles.

Therefore, finding a "just right" extrusion rate is a critical step in ensuring thermal gel performs at its best.

Core Factors Influencing Extrusion Rate Selection

Selecting the appropriate thermal gel extrusion rate requires a comprehensive consideration of the following core factors:

1. Rheological Properties of Thermal Gel

This is the most fundamental and crucial factor determining the extrusion rate. Different thermal gel formulations exhibit vast differences in their rheological parameters like viscosity and thixotropy:

▪ Viscosity: Gels with lower viscosity flow better under the same pressure, allowing for a slightly faster extrusion rate; conversely, high-viscosity gels require a slower extrusion rate to ensure uniform material flow.

▪ Thixotropy: Highly thixotropic gels experience a significant drop in viscosity (become thinner) under shear stress, and then rapidly recover their original viscosity (thicken) once the shear stress is removed. For these materials, careful control of shear forces during extrusion is necessary to ensure they quickly recover in the application area and maintain their shape.

Recommendation: Before selecting extrusion equipment, always consult the thermal gel's Technical Data Sheet (TDS) to understand its viscosity range and recommended operating temperature.

2. Dispensing Equipment and Process Parameters

The type of dispensing equipment and its settings directly influence the extrusion rate:

▪ Dispensing Valve Type: Screw valves, piston valves, jetting valves, etc., each have their own characteristics. Screw valves typically offer more precise flow control and are suitable for a wide range of viscosities; jetting valves are ideal for high-efficiency, non-contact dispensing.

▪ Dispensing Pressure: Higher pressure results in a faster extrusion rate. However, more pressure isn't always better; excessively high pressure can lead to material splashing or equipment wear.

▪ Nozzle Size: A larger nozzle aperture allows for a greater extrusion flow at the same pressure. Conversely, a smaller nozzle requires a slower rate.

▪ Dispensing Path and Speed: If the dispensing head moves quickly, the extrusion rate also needs to be increased accordingly to ensure continuous coverage.

Recommendation: For different equipment and processes, it's essential to conduct small-batch testing and adjustments to find the optimal combination of pressure, nozzle, and travel speed.

3. Thermal Gap and Coverage Requirements

The application scenario of thermal gel dictates the size and shape of the gap to be filled and the desired coverage:

▪ Gap Size: Larger gaps require more material to fill, potentially necessitating a slightly faster extrusion rate. Conversely, tiny gaps demand finer, slower extrusion.

▪ Coverage Shape: Is it a dot, line, or area coverage? Line coverage usually requires a constant extrusion rate, while dot coverage emphasizes the precision of a single dispense volume.

▪ Target Thickness: The desired final thickness of the thermal layer also influences the extrusion rate setting.

Recommendation: Clearly define the gap dimensions between the heat source and the heatsink, and determine the target thickness of the thermal gel according to design requirements.

How to Determine the "Right" Extrusion Rate?

Determining the appropriate extrusion rate is a systematic, experimental process, not a fixed value derivable from theoretical calculations alone. Here are the recommended steps:

1. Refer to Manufacturer's Recommendations

Most thermal gel suppliers provide recommended extrusion parameters or operating ranges in their product Technical Data Sheets (TDS). This is an excellent starting point to quickly narrow down your options.

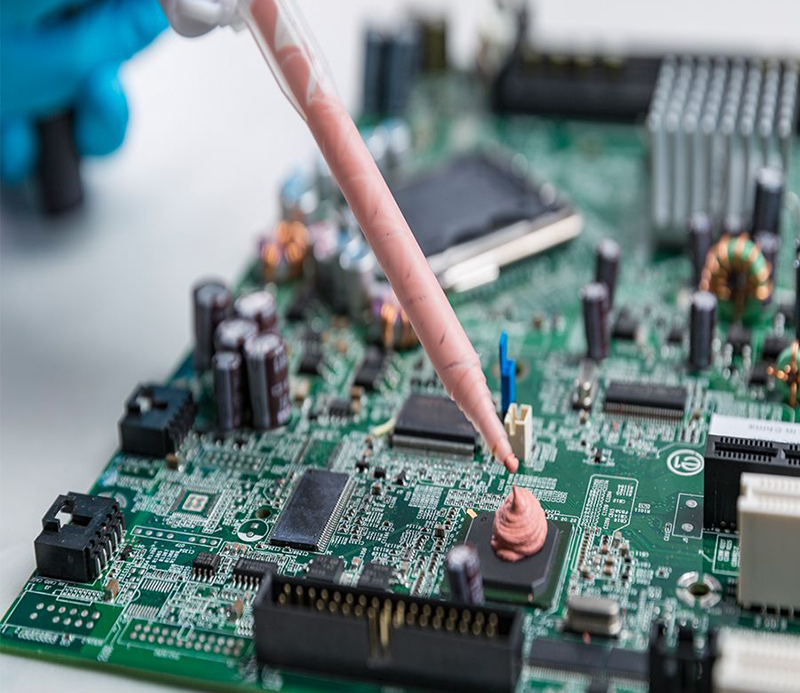

2. Small-Batch Prototyping and Visual Inspection

Before mass production, it is crucial to conduct small-batch prototyping. By adjusting extrusion pressure, nozzle size, dispensing speed, and other parameters, observe the extrusion results:

▪ Visual Inspection: Observe whether the coating is uniform and continuous, and if there are any air bubbles, breaks, or overflow.

▪ Measure Thickness: Use a thickness gauge or similar tool to check if the thickness of the coated thermal layer meets design requirements.

3. Thermal Performance Testing Verification

The ultimate criterion for judgment is the actual cooling performance. After coating, assemble the product and perform thermal performance testing:

▪ Temperature Monitoring: Monitor the temperature of the chip or heat source during operation.

▪ Comparative Analysis: Compare with products that have not been coated or have been coated with different extrusion rates to evaluate the quality of the cooling effect.

Rule of Thumb: It often requires multiple iterations and fine-tuning to find the optimal extrusion rate.

Tips and Precautions for Optimizing Extrusion Rate

▪ Preheat Thermal Gel: Some thermal gels experience increased viscosity at low temperatures. Appropriate preheating (following manufacturer's recommended temperature) can reduce their viscosity, making them easier to extrude and improving coating uniformity.

▪ Maintain Stable Environment: Fluctuations in ambient temperature and humidity can affect the rheology of thermal gel, thereby impacting extrusion results. Conduct dispensing operations in a constant temperature and humidity environment whenever possible.

▪ Regular Cleaning and Maintenance of Equipment: Clogged or worn dispensing valves and nozzles will directly affect extrusion rate and stability. Regular cleaning and maintenance of equipment are crucial for ensuring dispensing accuracy and consistency.

▪ Pay Attention to Shear Thinning Effect: For highly thixotropic thermal gels, shear thinning may occur during high-speed extrusion, leading to difficulty in maintaining shape after coating. In such cases, it might be necessary to adjust the extrusion rate or choose a material with a less pronounced shear thinning effect.

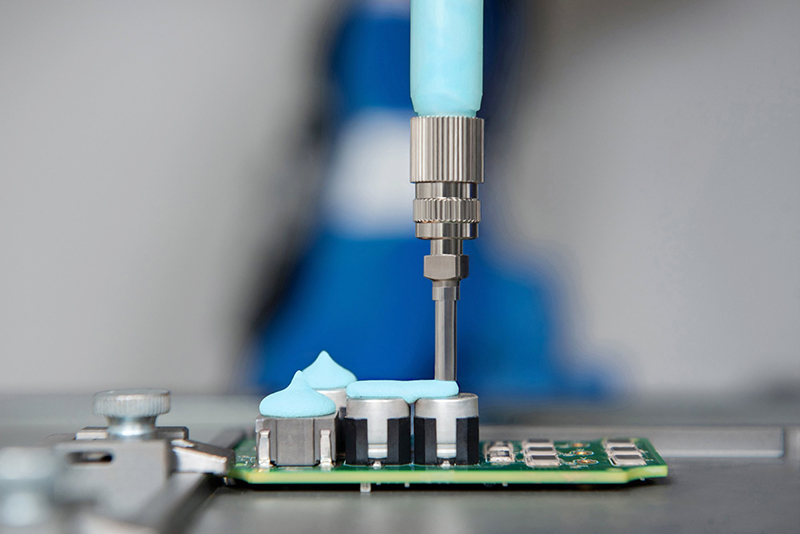

▪ Automation and Precise Control: Modern automatic dispensing machines can achieve precise flow and position control, which is vital for ensuring consistency and repeatability of the extrusion rate.

Conclusion

The extrusion rate of thermal gel is not a "one-size-fits-all" answer; it's a dynamic optimization process. By deeply understanding material properties, skillfully operating dispensing equipment, and combining it with rigorous testing and verification, you can find the extrusion rate best suited for your application. This will maximize the thermal gel's cooling potential and ensure the stable operation of your electronic products. Remember, every meticulous adjustment can lead to superior cooling performance for your product!

CN >

CN >