Can Thermal Interface Pads Seal? Dispelling Myths and Uncovering the Truth

Author:NFION

Date:2025-07-25 16:03:52

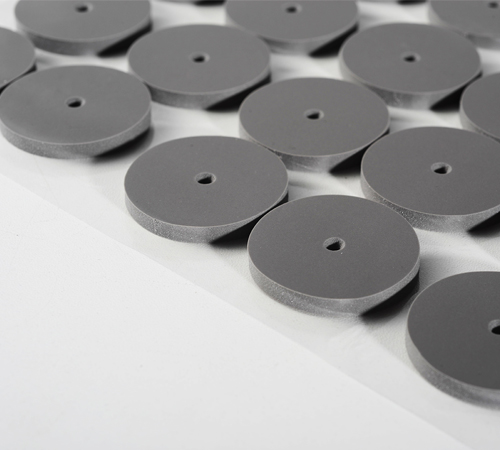

In the realm of electronics cooling, thermal interface pads (also known as thermal gap pads) are widely used due to their excellent thermal conductivity. However, many questions and even misconceptions exist regarding their ability to provide a sealing function. This article will delve into the characteristics of thermal interface pads, analyze their sealing capabilities, and correct common misunderstandings, aiming to provide clear and authoritative answers for professionals and users concerned about electronic product performance.

The Essence and Function of Thermal Interface Pads

To understand whether thermal interface pads can seal, we must first clarify their core function. As the name suggests, a thermal interface pad is a sheet material made of a silicone gel base, with added thermally conductive fillers (such as aluminum oxide, boron nitride, etc.). Its primary purpose is to fill the tiny gaps between heat-generating components and heat sinks, displacing air, thereby effectively reducing thermal resistance and improving thermal efficiency. It possesses a certain degree of softness, compressibility, and electrical insulation, allowing it to conform well to uneven contact surfaces.

Exploring the Sealing Capability of Thermal Interface Pads

So, can thermal interface pads really seal? The answer is: Thermal interface pads typically do not possess a sealing function in the traditional sense, but they can provide a certain degree of physical isolation.

▪ Not a Gas Sealing Material: Traditional sealing, especially gas sealing or liquid sealing, typically requires materials to have extremely low permeability and the ability to form a continuous, pore-free barrier under pressure. While thermal interface pads are dense, at a microscopic level, their internal structure may still contain micropores, and their primary design goal is not to block gases or liquids. Therefore, they cannot completely prevent the penetration of gases or liquids like professional O-rings, sealants, or gaskets.

▪ Physical Barrier Effect: Although they cannot achieve absolute sealing, thermal interface pads can provide a physical barrier to some extent. When compressed between two surfaces, they can effectively block dust and particulate matter from entering the interior and, to a certain extent, slow down the penetration speed of moisture or water vapor. This barrier effect is beneficial for protecting internal sensitive components from external environmental contamination.

▪ Compression Deformation and Conformance: The compression deformation ability of thermal interface pads allows them to conform tightly to contact surfaces, reducing air gaps, which indirectly enhances their physical barrier effect. In this tightly conformed state, their barrier effect might be mistaken for "sealing" in some non-critical applications that do not require high sealing performance.

Common Misconceptions Explained

1. Misconception One: Thermal interface pads can replace waterproof seals.

Truth: Thermal interface pads do not possess the waterproof and dustproof ratings (e.g., IP ratings) of waterproof seals. In humid or dusty environments, if a specific protection level is required, professional waterproof sealing materials must be used. Using thermal interface pads as the primary waterproofing method may lead to water or dust ingress and damage to the device.

2. Misconception Two: After using thermal interface pads, devices no longer need other moisture-proof measures.

Truth: Thermal interface pads can only provide limited moisture barrier protection and cannot completely prevent moisture corrosion. Especially in high-humidity environments, devices still need to rely on structural design, moisture-proof coatings, or other desiccants for comprehensive moisture protection.

3. Misconception Three: Softer thermal interface pads have better sealing effects.

Truth: The softness of thermal interface pads does help them fill gaps and conform to surfaces, thereby enhancing their physical barrier effect. However, overly soft materials may lead to pump-out effects (i.e., material loss during long-term thermal cycling and pressure), which can negatively impact long-term stability and thermal performance. Therefore, choosing appropriate hardness and compression ratio is more critical.

Conclusion and Recommendations

In summary, the core function of thermal interface pads is thermal conduction, not sealing. They can provide a certain degree of physical isolation, blocking dust and slowing down moisture penetration, but this is fundamentally different from professional sealing materials in terms of function and effect.

In practical applications, we should:

▪ Clarify Needs: If your primary need is heat dissipation, thermal interface pads are an excellent choice.

▪ Differentiate Functions: If strict waterproof, dustproof, or gas sealing effects are required, be sure to use professional sealing materials and structural designs.

▪ Comprehensive Consideration: In some specific applications, the physical barrier properties of thermal interface pads can serve as auxiliary protection, but they should never replace professional sealing solutions.

Understanding the true capabilities of thermal interface pads and avoiding misconceptions will enable you to make more informed decisions in electronic product design and repair, ensuring device performance and reliability.

Have you encountered application scenarios in your devices that require both high sealing and heat dissipation? Feel free to share your experiences and challenges.

CN >

CN >