Thermal conductive silicone pads, as a key thermal management material, are widely used in electronic devices, and their performance directly affects the heat dissipation and operational stability of these devices. When choosing thermal conductive silicone pads, hardness is an important parameter. A common misconception is that the lower the hardness, the better the silicone pad. So, is lower hardness really better for thermal conductive silicone pads? NFION will delve into this issue, providing comprehensive information and perspectives.

Basic Characteristics of Thermal Conductive Silicone Pads

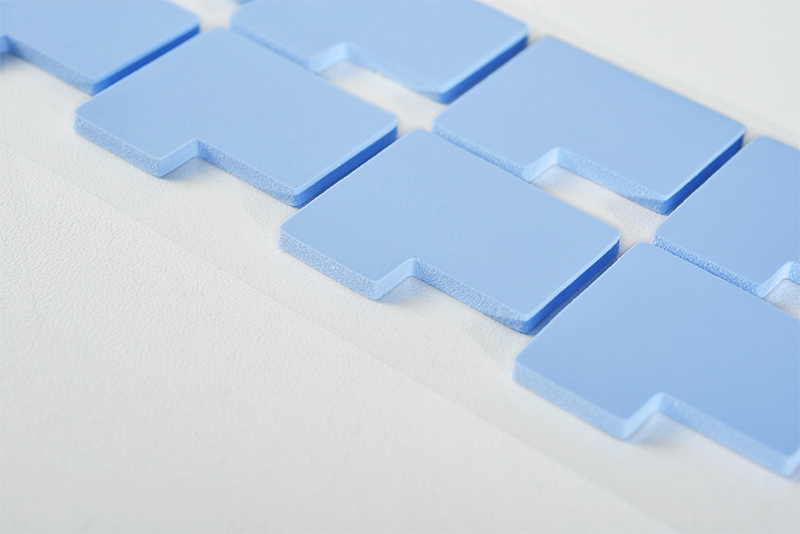

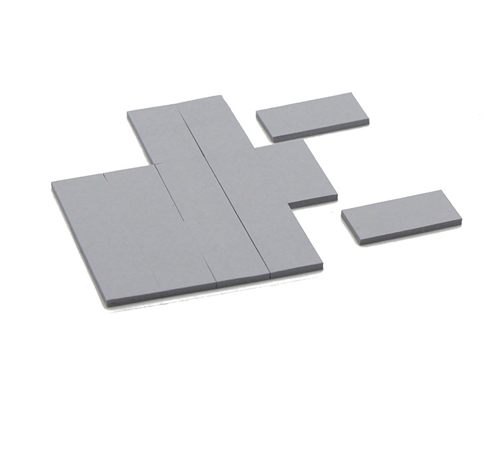

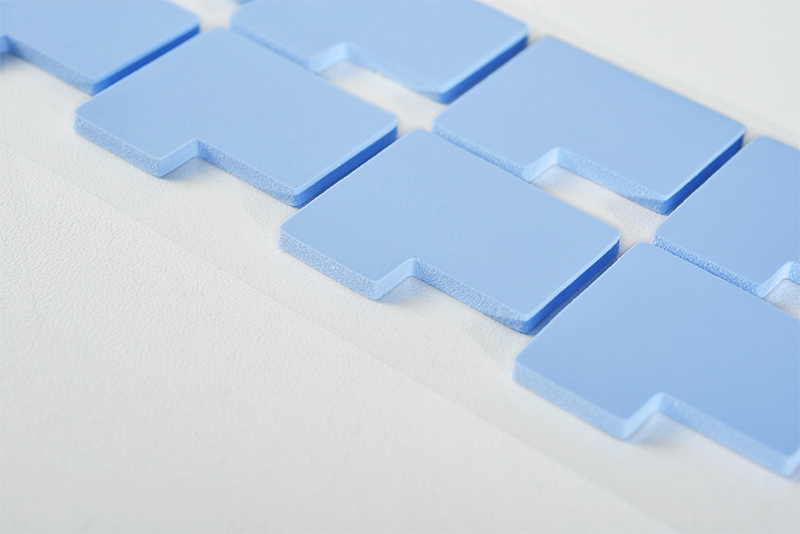

Thermal conductive silicone pads are materials with good thermal conductivity and electrical insulation properties, usually made from silicone and thermal conductive fillers. Their main function is to fill the gaps between electronic components and heat sinks, reducing contact thermal resistance and enhancing thermal efficiency. Performance parameters of thermal conductive silicone pads include thermal conductivity, hardness, thickness, and compressibility.

Definition and Impact of Hardness

Hardness refers to the material's ability to resist external forces pressing or scratching into it, usually measured in Shore Hardness. The hardness of thermal conductive silicone pads affects their conformity to contact surfaces and contact thermal resistance. Generally, lower hardness silicone pads are softer, better filling small gaps, increasing contact area, thereby reducing contact thermal resistance and improving thermal efficiency.

However, excessively low hardness silicone pads have drawbacks. Firstly, too soft silicone pads can easily deform under high pressure, potentially leading to uneven thickness and affecting overall thermal performance. Secondly, low hardness silicone pads may experience flow or permanent compression deformation over long-term use, reducing reliability.

Application Scenarios and Hardness Selection

In practical applications, the choice of hardness for thermal conductive silicone pads should be balanced based on specific needs and usage environments.

1. High-Pressure Environments: In applications requiring high pressure for conformity, such as high-power electronic devices and large heat sinks, appropriately increasing the hardness of the thermal conductive silicone pad can ensure it does not deform excessively under high pressure, maintaining stable thermal performance.

2. Low-Pressure Environments: In low-pressure environments with flat contact surfaces, choosing lower hardness silicone pads can better fill small gaps and enhance thermal performance.

3. Long-Term Reliability: For devices requiring long-term stable operation, the hardness and durability of thermal conductive silicone pads should be considered. Excessively low hardness silicone pads may deform under long-term compression, affecting thermal performance and device stability.

Other Factors Affecting Thermal Performance

Apart from hardness, other parameters such as thermal conductivity, thickness, and compressibility of thermal conductive silicone pads also significantly impact their thermal performance.

1. Thermal Conductivity: Higher thermal conductivity of silicone pads improves thermal performance. Given appropriate hardness, selecting materials with high thermal conductivity can significantly enhance heat dissipation.

2. Thickness: The thickness of thermal conductive silicone pads directly affects thermal resistance. Excessive thickness can increase thermal resistance, reducing thermal efficiency. Therefore, appropriate thickness should be selected based on specific applications.

3. Compressibility: The compressibility of thermal conductive silicone pads determines their deformation ability under pressure. Good compressibility helps the silicone pad conform better to contact surfaces during installation, enhancing thermal performance.

Conclusion

In summary, the hardness of thermal conductive silicone pads is not necessarily better when lower. The choice of hardness should be comprehensively considered based on specific application needs, usage environment, and other performance parameters. Low hardness silicone pads can provide excellent thermal performance in some low-pressure environments, but in high-pressure or long-term stable operation scenarios, appropriately increasing hardness to ensure deformation stability and durability is equally important. Therefore, when selecting thermal conductive silicone pads, multiple factors such as hardness, thermal conductivity, thickness, and compressibility should be considered to ensure optimal thermal performance and device reliability.

CN >

CN >