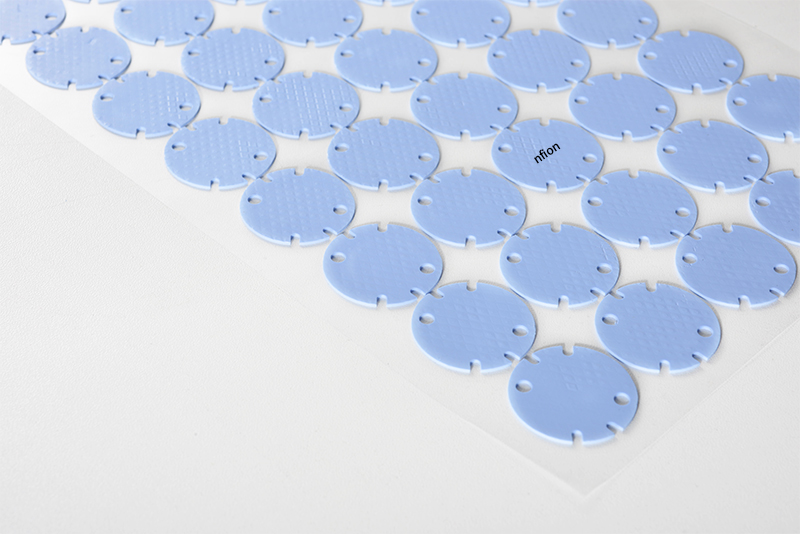

Thermally conductive silicone sheets are critical components in modern electronics and other high-tech industries, where efficient heat dissipation is paramount. These sheets serve as thermal interface materials (TIMs) that help manage heat generated by electronic components, ensuring optimal performance and longevity. NFION delves into the composition, functionality, applications, and benefits of thermally conductive silicone sheets, providing a comprehensive understanding of their importance in various technological domains.

Composition and Properties

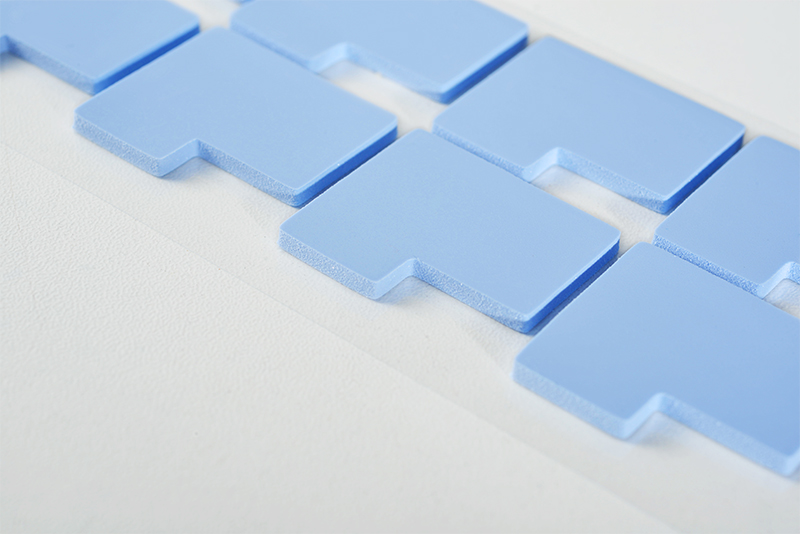

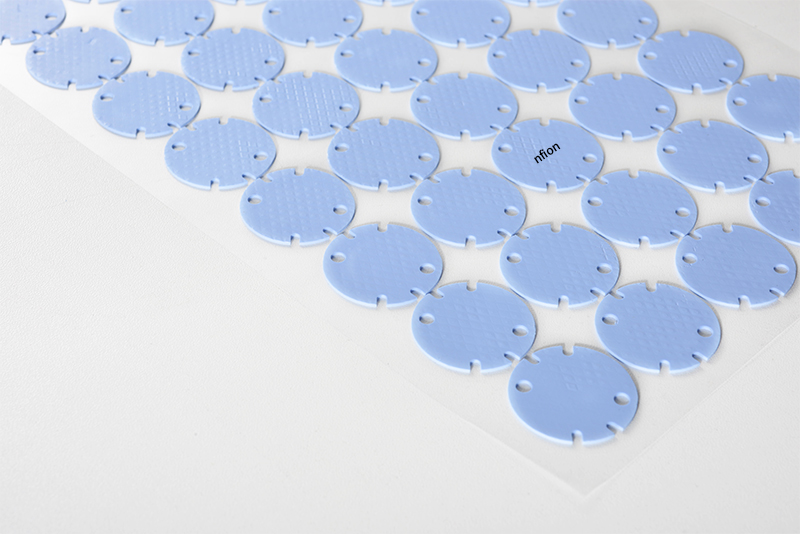

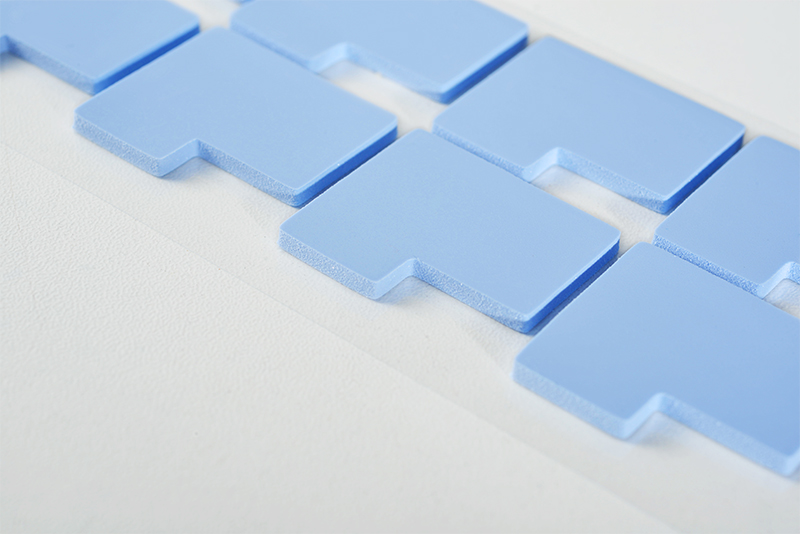

Thermally conductive silicone sheets are typically composed of silicone rubber infused with thermally conductive fillers, such as ceramic particles, graphite, or metallic oxides. The silicone matrix offers flexibility and resilience, while the fillers enhance the material's thermal conductivity. The key properties of these sheets include:

1. Thermal Conductivity: The primary function is to transfer heat away from heat-generating components. The thermal conductivity of these sheets can vary, typically ranging from 1 to 10 W/mK, depending on the filler materials and concentration.

2. Electrical Insulation: Many thermally conductive silicone sheets are also electrically insulating, preventing electrical short circuits while allowing efficient heat transfer. This dual functionality is particularly useful in electronics where both thermal management and electrical insulation are crucial.

3. Flexibility and Conformability: Silicone's inherent flexibility allows the sheets to conform to uneven surfaces, ensuring a close contact and minimizing thermal resistance at the interface.

4. Durability: These sheets are resistant to environmental factors such as temperature fluctuations, UV exposure, and chemical degradation, ensuring long-term reliability in harsh conditions.

Functionality

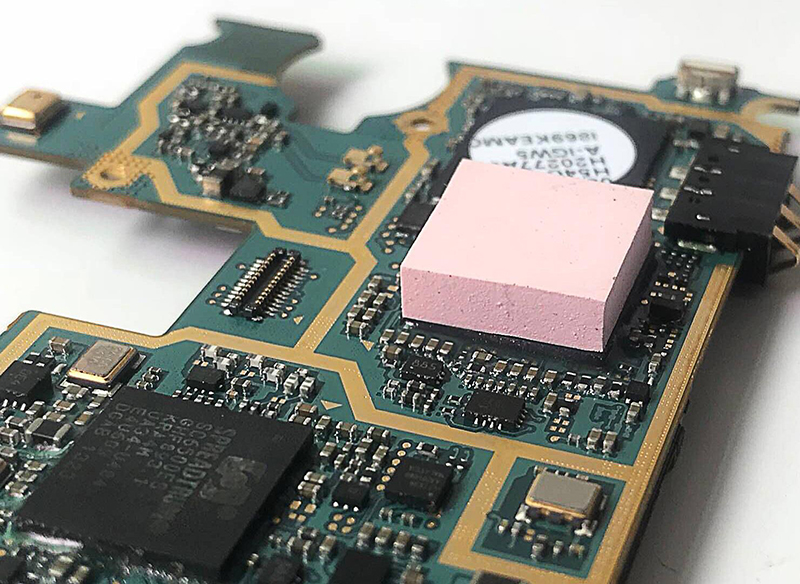

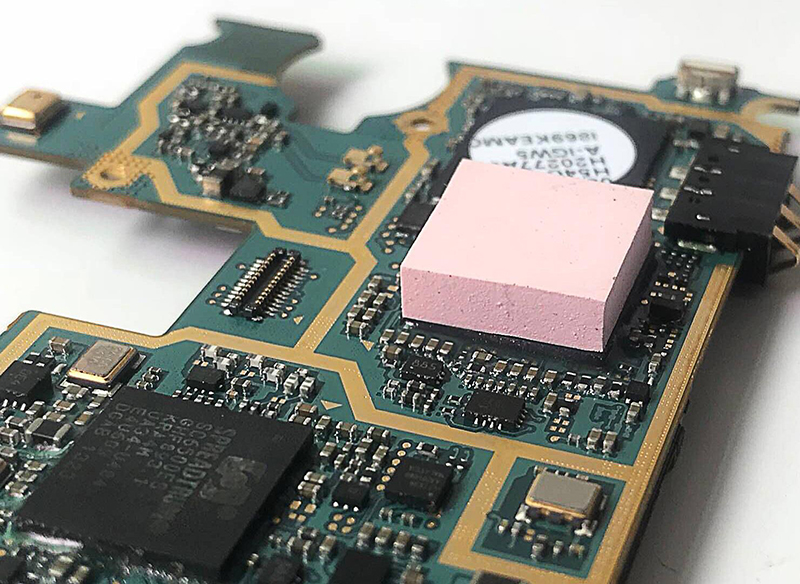

Thermally conductive silicone sheets function as effective thermal interfaces between heat sources (like microprocessors, power transistors, and LEDs) and heat sinks or other cooling devices. They fill microscopic air gaps and surface irregularities, which can significantly impede heat transfer. By providing a more direct thermal path, these sheets enhance the efficiency of heat dissipation, thereby maintaining the performance and extending the lifespan of electronic components.

Applications

The versatility of thermally conductive silicone sheets makes them suitable for a wide range of applications, including:

1. Electronics and Semiconductors: Used extensively in computers, smartphones, and other consumer electronics to manage heat from CPUs, GPUs, and power ICs.

2. Automotive Industry: Employed in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to dissipate heat from battery packs, inverters, and other electronic modules.

3. LED Lighting: Essential in LED lighting systems to prevent overheating and ensure consistent light output and longevity.

4. Telecommunications: Utilized in network equipment and base stations to maintain optimal operating temperatures of high-frequency components.

5. Medical Devices: Applied in medical electronics where thermal management is crucial for the reliability and safety of diagnostic and therapeutic equipment.

Benefits

The benefits of using thermally conductive silicone sheets are manifold:

1. Enhanced Thermal Management: By efficiently conducting heat away from critical components, these sheets help prevent overheating, thereby enhancing the performance and reliability of electronic systems.

2. Electrical Insulation: The dual functionality of thermal conductivity and electrical insulation makes these sheets ideal for use in high-voltage applications where electrical isolation is required.

3. Ease of Application: The flexibility and conformability of silicone sheets make them easy to apply, reducing installation time and ensuring a snug fit around complex geometries.

4. Longevity and Reliability: Resistant to environmental stressors, these sheets offer long-term stability and performance, even in challenging conditions.

Conclusion

Thermally conductive silicone sheets play a pivotal role in modern thermal management solutions, addressing the ever-increasing heat dissipation needs of advanced electronic systems. Their unique combination of thermal conductivity, electrical insulation, flexibility, and durability makes them indispensable across various industries. As technology continues to advance, the demand for efficient and reliable thermal management solutions like thermally conductive silicone sheets is expected to grow, underscoring their importance in the future of electronics and beyond.

CN >

CN >