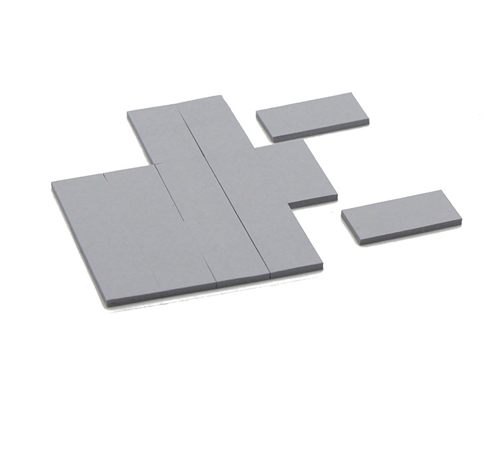

In the BMS, the primary function of thermal conductive silicone pads is to facilitate uniform heat conduction between battery cells. As batteries generate heat during operation, failure to expel this heat efficiently can lead to thermal runaway and potentially cause safety incidents. Thermal conductive silicone pads boast excellent thermal conductivity properties, enabling them to quickly transfer heat generated by battery cells to the cooling system, ensuring that the battery operates within a safe temperature range.

1. Enhanced Cooling Efficiency:

The soft and flexible nature of the thermal conductive silicone pad allows it to fill gaps between battery cells or between the battery and cooling components, effectively conducting heat while also providing insulation and shock-absorption.

2. Heat Spreading:

Inside the battery pack, individual cells may generate heat unevenly. The thermal conductive silicone pad distributes heat rapidly and uniformly across the entire cooling surface, helping balance temperature differences among parts.

3. Battery Safety Protection:

Beyond aiding in heat dissipation, the thermal conductive silicone pad acts as a buffer, safeguarding the long-term stability and reliability of the product.

4. Optimized Battery Performance:

By providing an efficient thermal path between battery components, the thermal conductive silicone pad helps distribute heat evenly, maintaining the battery's operation within a stable temperature range, which contributes to consistent performance and extends battery life.

5. Improved BMS Reliability:

The use of thermal conductive silicone pads can reduce the operating temperatures of BMS components, enhancing the overall stability of the battery, which is crucial for the BMS's continuous reliable operation.

6. Addressing Structural Stress Issues:

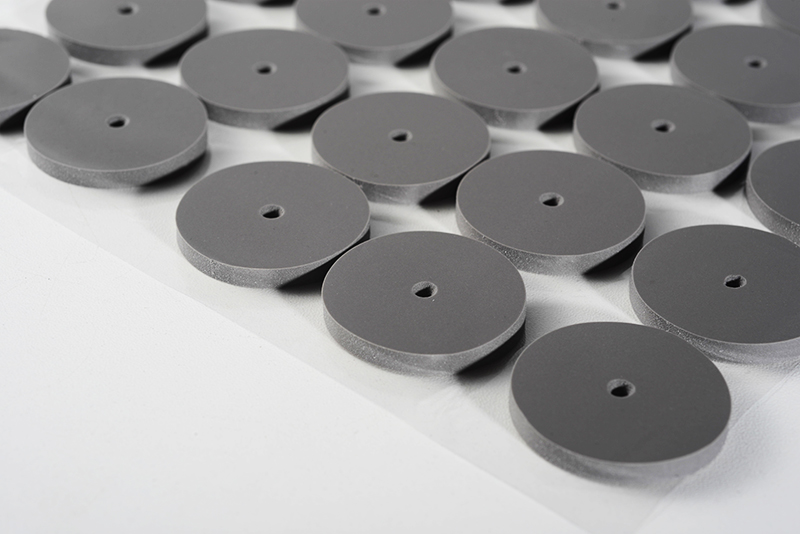

The thermal conductive silicone pad exhibits low stress on structures and maintains a small thermal resistance under low-pressure conditions. It can be custom-cut into various shapes, offering resistance to high and low temperatures, oxidation, and more.

7. Electrical Insulation Properties:

The thermal conductive silicone pad also possesses good electrical insulation properties, helping prevent issues such as current leakage or short circuits, thus ensuring electrical safety in the BMS.

8. Flame Retardant, Moisture-Resistant, Shock-Absorbent:

Some thermal conductive silicone pads feature flame retardancy, moisture resistance, and shock absorption properties, further enhancing the safety and reliability of the BMS.

9. Customizable Solutions:

Thermal conductive silicone pads can be customized according to practical application needs with varying hardness, thickness, thermal conductivity coefficients, voltage ratings, flame-retardant levels, and temperature ranges, meeting the thermal management requirements of different BMS systems.

10. Adhesive Bonding Fixation:

Some thermal conductive silicone pads have self-adhesive properties, securely bonding to contact surfaces, ensuring stable thermal contact while simplifying the assembly process of the BMS system.

CN >

CN >