In today's digital era, the set-top box, the cornerstone of home entertainment systems, has become a bridge connecting users with a wealth of multimedia content. With the continuous advancement of technology, set-top boxes have grown increasingly powerful and integrated, signifying not only enhanced processing capabilities but also posing challenges in heat dissipation. Against this backdrop, thermally conductive silicone sheets, as highly efficient thermal management materials, play a pivotal role in the design and manufacture of set-top boxes. This article delves into the working principles, advantages, specific applications of thermally conductive silicone sheets in set-top boxes, and their crucial impact on enhancing product performance and user experience.

I. Basics and Working Principles of Thermally Conductive Silicone Sheets

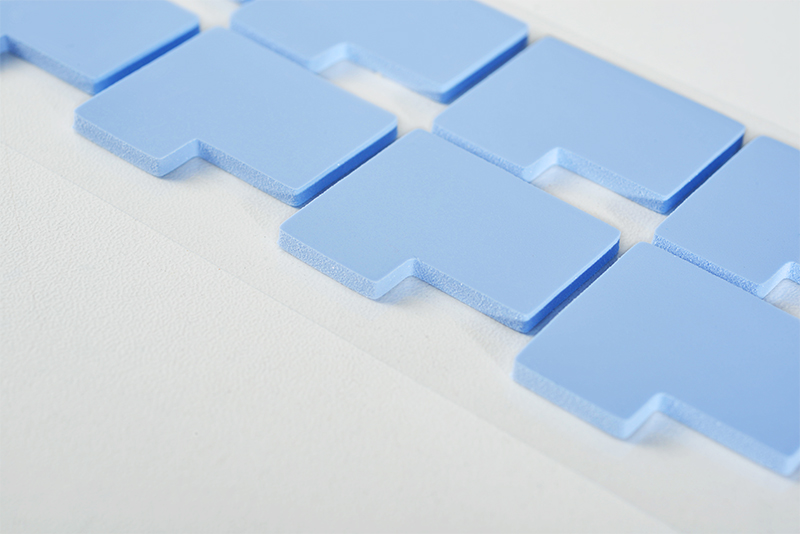

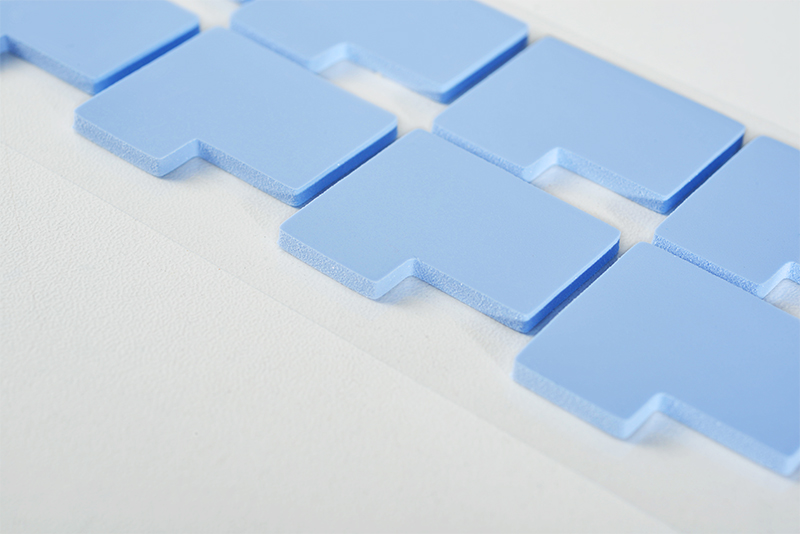

Thermally conductive silicone sheets are polymer materials prepared by adding thermally conductive fillers (such as aluminum oxide, boron nitride, etc.) to silicone through special processes. They retain the softness, elasticity, and insulation properties of silicone while enhancing the material's thermal conductivity through these fillers. Their working principle relies on the microstructure within the material to form heat transfer pathways, rapidly and evenly conveying heat generated by electronic components to heat sinks or casings, eventually dissipating it into the air to achieve cooling effects.

II. Advantages of Thermally Conductive Silicone Sheets

1. Excellent Thermal Conductivity: Compared to traditional thermal pads, thermally conductive silicone sheets offer higher thermal conductivity, enabling more effective heat transfer and reducing localized overheating.

2. High Adaptability: Due to their softness and compressibility, they can effectively fill minute gaps between electronic components and cooling structures, even on uneven surfaces, improving thermal conductivity efficiency.

3. Insulation and Stability: As insulating materials, they ensure efficient cooling while preventing short circuits, ensuring electrical safety, and maintaining stable physical and chemical properties over a wide temperature range.

4. Ease of Installation and Maintenance: Their self-adhesive design facilitates quick and easy installation, and their replaceability or upgrade is relatively straightforward, reducing production and maintenance costs.

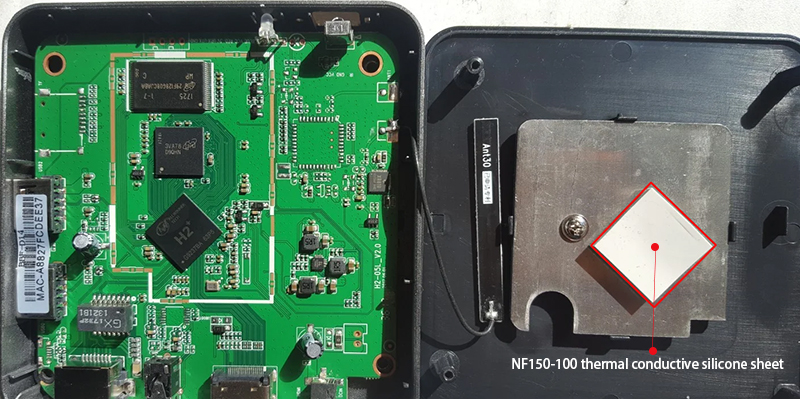

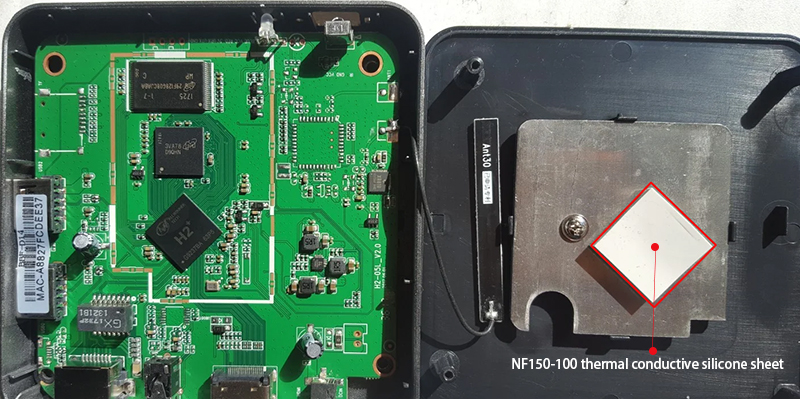

III. Specific Applications in Set-Top Boxes

Set-top boxes, as highly integrated electronic devices, house multiple heat sources such as CPUs, GPUs, memory, and power modules. Under high-load conditions like HD streaming, network transmission, and multitasking, the heat from these components must be dissipated promptly to avoid performance degradation, shortened lifespan, or system crashes. Thus, effective thermal management solutions are paramount in set-top box design.

1. CPU/GPU Cooling: As the primary heat sources, CPUs and GPUs directly contact thermally conductive silicone sheets, which swiftly transfer heat to heat sinks, ensuring processor operation within safe temperature ranges, thereby boosting computational efficiency.

2. Power Module Cooling: Power modules generate significant heat during energy conversion. Applying thermally conductive silicone sheets around or onto the surface of the power module effectively reduces temperature rise, prolonging its lifespan.

3. Auxiliary Cooling for Memory and Other IC Chips: Although memory and small IC chips generate less heat individually, their collective effect is notable. Adequate coverage with thermally conductive silicone sheets balances overall temperature distribution, reducing internal temperature gradients, and enhancing system stability.

4. Noise Reduction and Space Saving: Unlike active cooling methods like fans, passive cooling with thermally conductive silicone sheets produces no noise and occupies less space, facilitating the miniaturization of set-top boxes.

IV. Selection and Installation Considerations for Thermally Conductive Silicone Sheets

1. Selection of Thermal Conductivity: Different set-top boxes have varying requirements for thermal conductivity; generally, higher values yield better cooling but at increased costs. Therefore, choosing the right thermal conductivity for the set-top box’s specific needs and cooling requirements is essential.

2. Thickness Selection: The thickness of the silicone sheet also influences cooling performance, with thinner sheets generally offering lower thermal resistance and better cooling. However, excessively thin sheets may compromise mechanical strength and damping properties. A balanced consideration of thickness and other performance indicators is necessary.

3. Installation Precautions: Ensuring clean and flat surfaces on both heat sources and heat sinks is vital during installation to avoid impurities or protrusions that could impair thermal conductivity. Proper positioning and orientation of the silicone sheet are also critical to maximize its cooling function.

V. Impact on Product Performance and User Experience

Set-top boxes employing thermally conductive silicone sheets benefit from improved cooling efficiency, ensuring electronic components operate at optimal temperatures. This leads to:

- Enhanced system stability: Effective temperature control reduces system crashes or restarts due to overheating, improving the user experience.

- Boosted performance: A well-regulated thermal environment enables CPUs, GPUs, and other core components to operate at high efficiency, supporting higher resolution video playback and more complex computing tasks.

- Extended lifespan: Preventing heat damage to electronic components prolongs the set-top box’s lifespan, reducing replacement costs for users.

- Silent operation: Fanless designs minimize noise pollution, suiting households that prioritize quiet environments.

VI. Conclusion

In conclusion, the application of thermally conductive silicone sheets in set-top box design not only tackles the heat dissipation challenges of high-performance electronic devices but is also instrumental in elevating overall product performance and user satisfaction. As technology advances and consumer demands diversify, future research and application of thermal interface materials will become more refined and customized, invigorating the development of set-top boxes and the broader consumer electronics industry. For designers, a deep understanding of thermally conductive silicone sheets' characteristics and application methodologies is crucial to developing more efficient, reliable, and user-friendly products, leading the trend in digital entertainment lifestyles.

CN >

CN >