BMS stands for Battery Management System. It is a system responsible for monitoring, evaluating, controlling, and managing batteries, primarily in devices or systems incorporating rechargeable batteries, such as electric vehicles (EVs), energy storage systems, unmanned aerial vehicles (UAVs), and portable electronic devices. The primary objective of a BMS is to ensure the safe, efficient, and balanced operation of battery packs, prolong their lifespan, and provide accurate battery status information.

1.Parameter Monitoring: Real-time monitoring of critical parameters in the battery pack, including voltage, current, temperature, state of charge (SOC), state of health (SOH), and remaining useful life (RUL).

2.Safety Protection: Preventing battery anomalies such as overcharge, over-discharge, overheating, short-circuit, and overcurrent by disconnecting the charge/discharge circuit or adjusting charging/discharging strategies to protect the battery.

3.Balancing Management: Implementing active or passive balancing on individual cells within the battery pack to ensure consistent charge/discharge states among all battery units, reducing capacity loss and inconsistency.

4.State Estimation: Calculating battery status parameters like SOC and SOH based on monitored data, providing real-time information for system control and user interfaces.

5.Communication Interface: Exchanging data with external devices (e.g., vehicle control systems, energy storage system controllers, monitoring platforms) for remote monitoring and control.

6.Fault Diagnosis: Detecting faults and abnormal behavior in the battery system, providing fault alarm information, and potentially possessing some self-repair capabilities.

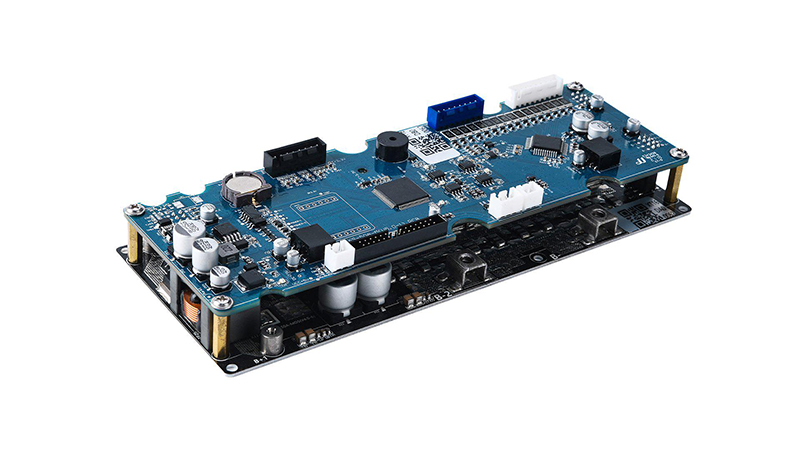

1.Motherboard: Main control unit responsible for data processing, strategy formulation, and overall control.

2.Daughterboards (or Acquisition Boards): Distributed within the battery pack and directly connected to individual cells, collecting battery parameters and sending them to the motherboard.

3.BDU (Battery Disconnect Unit) or High-Voltage Control Board: Incorporating high-voltage contactors, fuses, etc., for executing main power on/off control, ensuring safety.

4.AFE (Analog Front End) Chip: Analog frontend for acquiring battery voltage, current, temperature, and other analog signals, performing initial processing.

5.MCU (Microcontroller Unit) Chip: Microcontroller serving as the core processor of the BMS, responsible for data computation, state estimation, strategy control, and other advanced functions.

6.ADC (Analog-to-Digital Converter): Converts analog signals output by the AFE chip into digital signals for processing by the MCU.

7.Digital Isolators: Providing electrical isolation between subsystems with different voltage levels, ensuring communication safety.

8.Sensors: Including voltage sensors, current sensors, temperature sensors, etc., used for direct measurement of battery status.

Voltage Monitoring: Real-time measurement of the voltage of each individual cell in the battery pack through distributed voltage acquisition circuits or A/D converters (ADCs) to understand the electrochemical status and health of cells within the pack.

Current Monitoring: Monitoring the charge/discharge current of the battery pack using current sensors (such as Hall effect sensors, shunts, etc.) for calculating power, energy, and assessing battery operational status.

SOC (State of Charge) Calculation: Based on acquired voltage, current, temperature data, combined with battery models, historical data, and specific algorithms (e.g., Coulomb counting, open-circuit voltage method, Kalman filtering), estimating the battery's state of charge (remaining capacity).

SOH (State of Health) Assessment: Through long-term monitoring of battery performance parameters (e.g., increasing internal resistance, capacity fade), coupled with aging models and diagnostic algorithms, evaluating the battery's health status and residual lifetime.

Overcharge/Overdischarge Protection: When an individual cell's voltage exceeds a preset upper limit or falls below a preset lower limit, the BMS immediately interrupts the charging/discharging process to prevent battery damage due to overcharge or overdischarge.

Overtemperature Protection: If the battery temperature exceeds safe limits, the BMS initiates cooling systems or restricts charge/discharge currents, potentially disconnecting power if necessary, to prevent thermal runaway risks.

Overcurrent/Short-Circuit Protection: Upon detecting excessively high charge/discharge currents or short-circuit conditions, the BMS swiftly severs the circuit to prevent battery damage or ignition of fires.

Passive Balancing: When the voltage difference between cells in the battery pack reaches a certain threshold, dissipating excess energy from higher-voltage cells through resistive methods to lower-voltage cells, thereby reducing voltage inconsistency.

Internal Communication: Using communication interfaces like CAN bus, RS-485, LVDS, the BMS motherboard exchanges data with sub-systems such as slave controllers, acquisition modules, cooling systems, enabling information sharing and coordinated control.

Real-time Monitoring & Alarms: Continuously monitoring the battery system's status, identifying anomalies such as single-cell failures, communication failures, sensor failures, and promptly issuing alarm signals.

Tag: BMS battery management system thermal management

Article Link:www.nfionthermal.com/Article/s266.html

CN >

CN >