NF150-300 High Thermal Conductivity Silicone Pad Empowering Efficient Heat Dissipation in 5G Integrated Base Stations

Heat Dissipation Challenges and Strategic Value of Domestic Substitution in the 5G Era

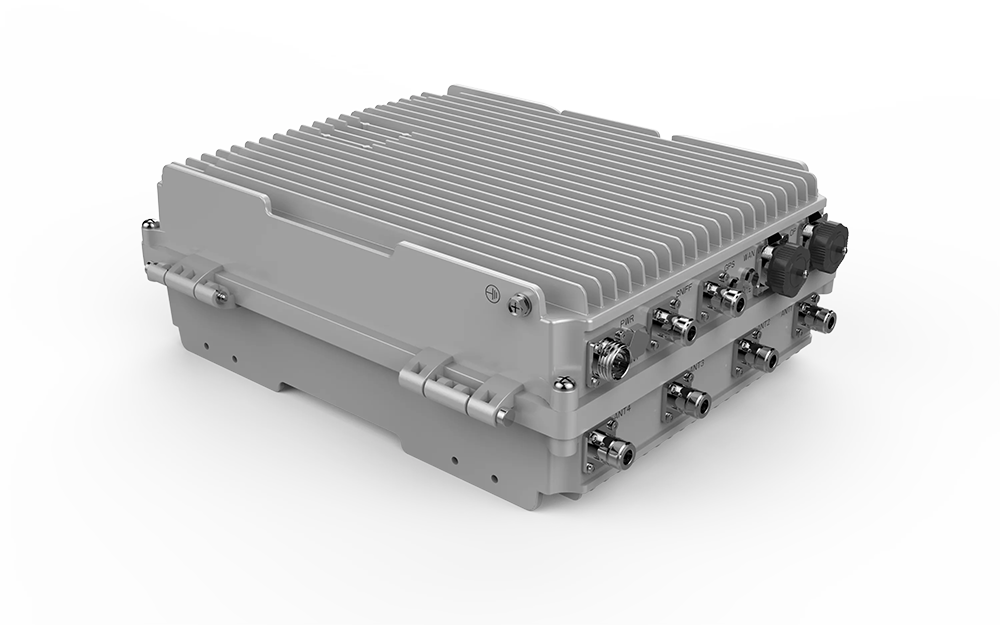

With the widespread adoption of 5G technology, integrated base stations, as its core infrastructure, are facing unprecedented thermal management challenges. Compared with 4G, the power density of 5G base stations has increased by about 2–3 times, significantly raising the heat generated by power amplifiers and processing chips. If heat cannot be dissipated effectively, excessive core temperatures will lead to performance degradation, reduced lifespan, and even failure.

For a long time, the high-end thermal interface materials market has been dominated by foreign brands, increasing supply chain risks and limiting the independence of domestic industries. Against this backdrop, the NF150-300 series high thermal conductivity silicone pads emerged. Not only do they rival imported brands in performance, but they also provide strategic value in supply chain security, cost optimization, and local support.

Overcoming Thermal Challenges: NF150-300’s Superior Performance

1. Efficient Heat Transfer for Stable Performance

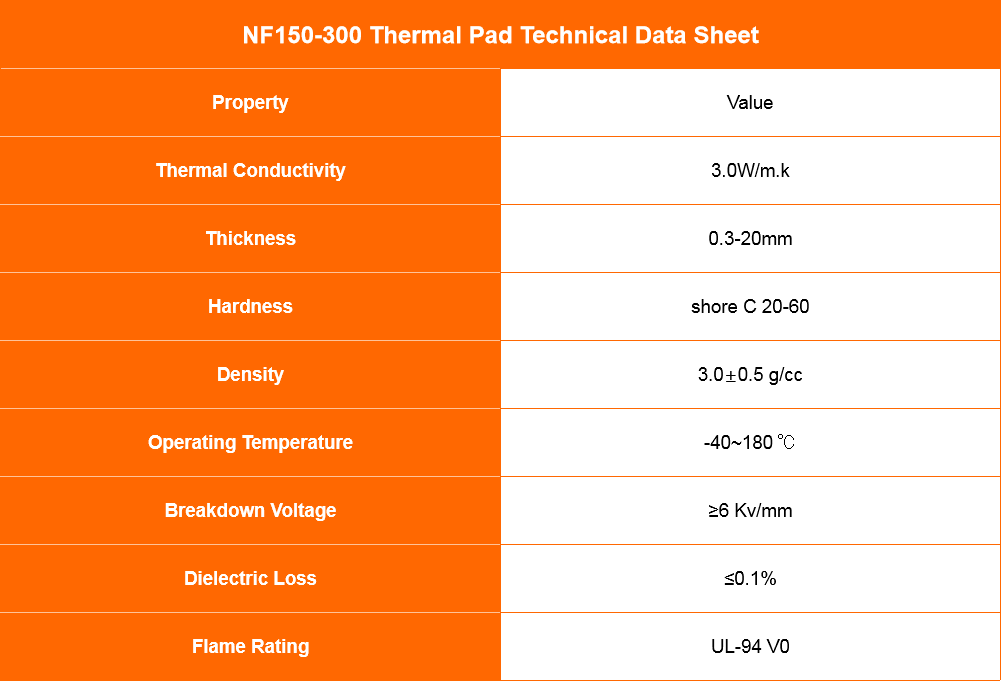

The NF150-300 offers a thermal conductivity of 3.0 W/m·K, 50–100% higher than conventional silicone pads (1.5–2.0 W/m·K), reaching the level of international high-end products. It efficiently transfers the heat generated by components such as power amplifiers and DSP chips to heat sinks, significantly reducing interface thermal resistance and keeping critical devices within safe operating temperatures.

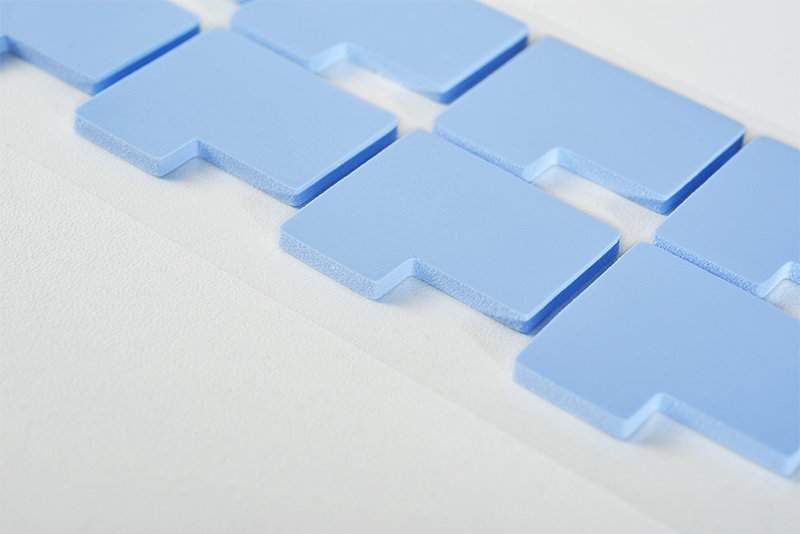

2. Excellent Flexibility and Compressibility for Perfect Conformability

With the compact structure of 5G base stations, gaps or uneven surfaces between components and heat sinks are common. The NF150-300, with its excellent flexibility and compressibility (Shore 00 hardness 20–50 optional), deforms under slight pressure to fill gaps and eliminate air layers. This perfect conformability further reduces interface thermal resistance, enhancing overall heat transfer efficiency.

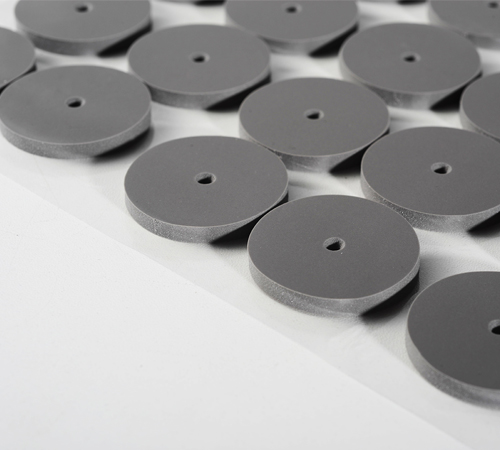

3. Wide Thickness Range for Diverse Design Needs

Available in 0.3mm–15mm thickness options and customizable sizes, NF150-300 provides engineers with flexible solutions to precisely match varying design requirements.

4. Long-Term Reliability in Harsh Environments

NF150-300 operates reliably within -40℃ to 150℃, with excellent resistance to aging and high temperatures. It has passed ASTM D5470 thermal resistance testing and meets the UL94 V-0 flammability standard, ensuring long-term stability even in harsh outdoor conditions.

5. High Electrical Insulation for Safety and Stability

With a breakdown voltage of ≥6 kV/mm, NF150-300 provides excellent electrical insulation, effectively preventing short circuits and ensuring safe operation under high load.

6. Compliance with Environmental Standards

NF150-300 fully meets RoHS and REACH environmental requirements, free from hazardous substances, aligning with global green manufacturing and sustainability trends.

Application Scenarios: A Key Role in Integrated Base Stations

NF150-300 is widely applied in:

● BBU/RRU Modules: Between power amplifiers, DSP, FPGA chips and heat sinks.

● Power Modules: Ensuring stable operation by dissipating power IC heat.

● PCB Boards: Acting as a thermal gap filler to transfer heat to chassis or heat sinks.

Case Study: Achieving Supply Chain Localization

A leading domestic small-cell manufacturer, previously reliant on imported pads, introduced NF150-300 into its 5G RRU products to achieve supply chain independence and cost reduction.

Test Conditions: Simulated summer high-temperature environment (45℃), RRU at full power continuous operation.

Comparison: NF150-300 vs. imported pad.

Results:

● Core chip temperature: Both stabilized at~80℃, meeting design requirements.

● Power amplifier peak temperature: Reduced by 2–3℃ with NF150-300.

● Comprehensive value: With equivalent performance, NF150-300 shortened delivery lead time by 30%, reduced procurement cost by 20%, and offered faster local technical support, effectively mitigating supply chain risks.

This case demonstrates NF150-300’s competitiveness in both performance and reliability, proving it a viable domestic substitution for imported brands.

Conclusion: NF150-300, A Model of Domestic Substitution

The NF150-300 high thermal conductivity silicone pad, with its 3.0 W/m·K thermal conductivity, excellent flexibility and compressibility, wide thickness adaptability, long-term reliability, high insulation, and environmental compliance, provides efficient and reliable thermal management for 5G integrated base stations.

It not only addresses thermal challenges with precision but also enhances equipment lifespan, reduces maintenance costs, and strengthens supply chain security. NF150-300 stands as a successful example of domestic substitution in the 5G era and a driving force for industry autonomy.

CN >

CN >