China’s Thermal Pad Revolution: Who Will Break the Foreign Monopoly?

Author:NFION

Date:2025-10-14 11:42:20

01|Introduction: Localization — From an Option to a Necessity

As global manufacturing undergoes structural reshaping, supply chain security and technological independence have become fundamental strategies.

In this shift, silicone thermal pads — often the invisible core of thermal management — are now at the center of attention.

For years, the high-end thermal interface materials (TIMs) market was dominated by foreign brands. From raw material systems to process stability, domestic manufacturers had to rely heavily on imports.

However, with the rapid rise of new energy vehicles, 5G communication, and AI computing, the localization of silicone thermal pads is no longer a vision — it’s an inevitable path to securing industrial resilience and competitiveness.

02|The Hidden Risk: A “Choke Point” Behind a Small Silicone Pad

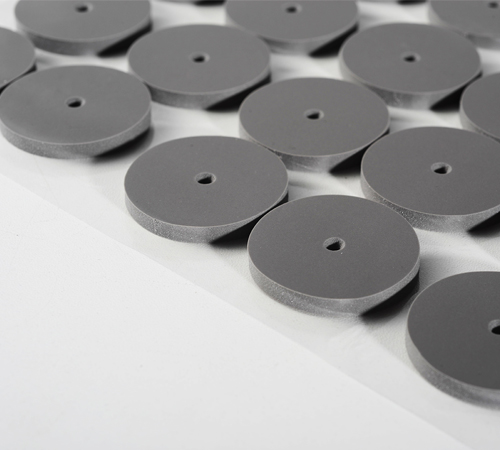

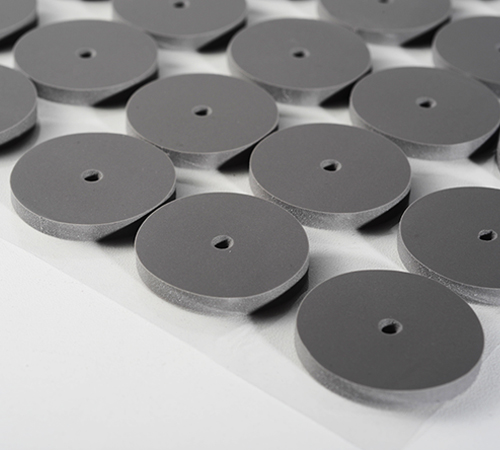

A silicone thermal pad may look insignificant, yet it’s essential for the stable operation of electronics.

It conducts heat, provides insulation, and buffers mechanical stress between chips, modules, and heat sinks.

However, for a long time, high-performance silicone thermal pads were monopolized by Japanese and American brands.

The hidden dependency created multiple risks:

● Supply vulnerability – geopolitical tensions or trade barriers can disrupt supply;

● High costs – imported materials mean higher prices, long lead times, and poor flexibility;

● Technology lock-in – key formulations and production know-how remain tightly guarded.

Therefore, the localization of silicone thermal pads is not just about cost reduction — it’s a strategic imperative for industrial sovereignty.

03|Breakthrough and Rise: The Acceleration of Domestic Innovation

After more than a decade of dedicated R&D, Chinese material enterprises are rapidly breaking through technical barriers.

Leading manufacturers such as NFION are narrowing the gap with international players and, in some segments, even achieving performance parity or superiority.

Key strengths of domestic silicone thermal pads:

✅ Enhanced thermal conductivity

Stable performance from 1.0 to 13.0 W/m·K, suitable for automotive controllers, AI servers, and communication modules.

✅ Reliability on par with imports

Validated by major OEMs and Tier-1 suppliers, meeting long-term aging and mechanical endurance standards.

✅ Faster local response

Rapid prototyping and flexible customization — lead times shortened from weeks to days.

✅ Comprehensive certifications

UL, RoHS, REACH, and IATF16949 compliance ensure qualification for automotive and industrial applications.

Domestic silicone thermal pads have now transitioned from “available” to “trusted,” earning recognition across major industries.

04|Industry Transformation: From Substitution to Leadership

Localization is not the end — it’s the beginning of a new competitive paradigm.

With continuous advancements in technology, cost control, and delivery, China’s thermal materials industry is evolving toward a fully integrated chain — from raw materials to system-level applications.

The next stage of competition will extend beyond single material performance to complete thermal management solutions:

Manufacturers will collaborate with clients in thermal simulation, structural design, and reliability validation — realizing end-to-end optimization.

The advantages of localized collaboration are becoming increasingly prominent:

● Closer R&D alignment with customer projects;

● Rapid response to new-generation designs;

● Digitalized production ensures batch stability and full traceability.

This is not merely industrial substitution — it’s a redefinition of value creation within the global supply chain.

05|Conclusion: Owning the “Heat Advantage” Defines Future Competitiveness

The localization of silicone thermal pads is a strategic battle that spans technology, supply chain, and national resilience.

The true differentiator lies not just in formulation, but in the ability to understand thermal design needs and establish a complete R&D-to-application feedback loop.

As more Chinese enterprises master their own technologies and gain international trust,

“Made in China” thermal materials will no longer be substitutes — but indispensable global standards.

Breaking the monopoly is the start; mastering control is the goal.

The rise of domestic silicone thermal pads marks not just industrial progress — but a new chapter in the story of China’s manufacturing power.

CN >

CN >