In today's increasingly miniaturized and highly integrated electronic products, heat dissipation has become a critical bottleneck limiting their performance and reliability. Thermal interface materials, as the core solution to this problem, directly influence the "healthy" operation of electronic devices. Today, we'll focus on a highly anticipated product in the thermal management field – the NF150-300 thermal conductive pad – to delve into its performance and help you fully understand the unique advantages of this material.

NF150-300: Why Does It Deserve Your Attention?

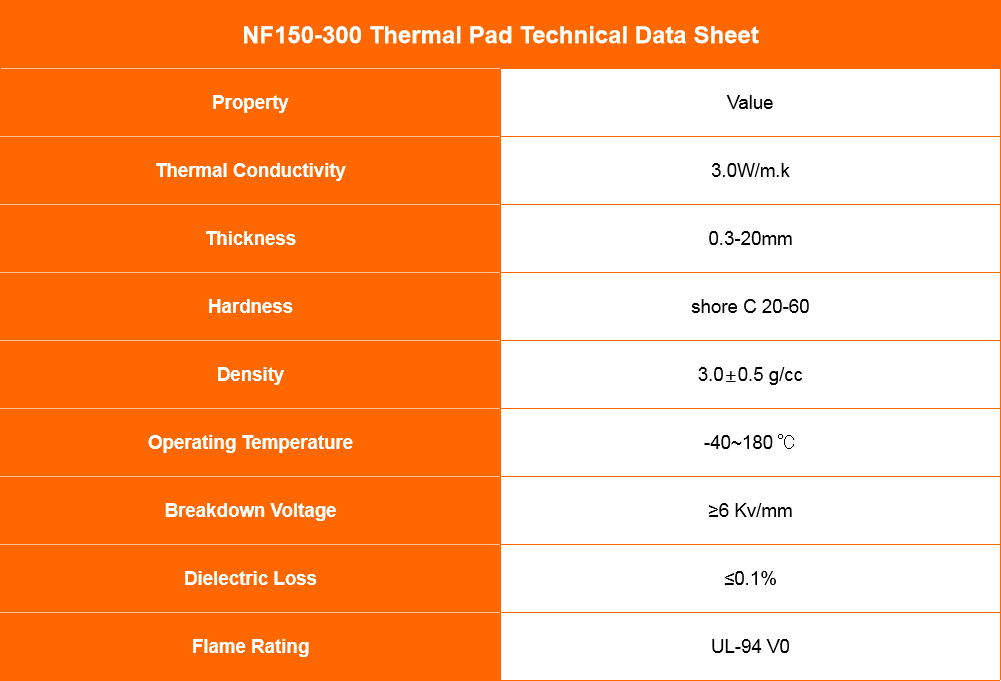

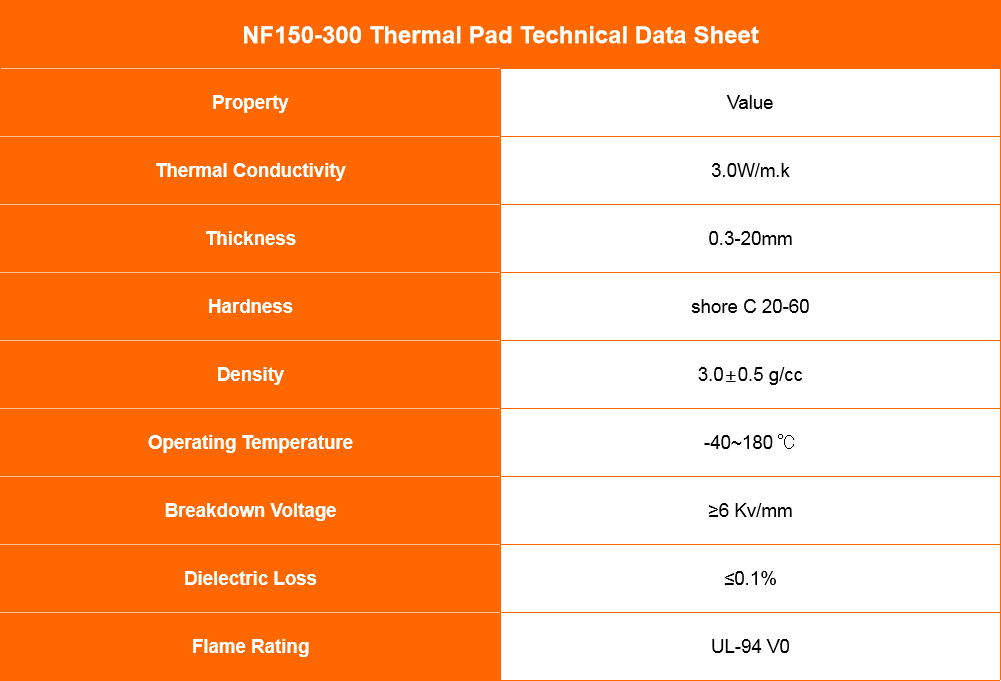

The NF150-300 thermal conductive pad is an excellent thermal conductive material with a thermal conductivity of up to 3.0 W/m·K. This high thermal conductivity gives it broad application prospects in various electronic devices, effectively addressing the increasingly severe challenges of heat dissipation. However, knowing just the thermal conductivity isn't enough; its comprehensive performance is what we truly need to focus on.

Performance Deep Dive: More Than Just Thermal Conductivity

1. Excellent Thermal Efficiency: The "Highway" for Heat Transfer

The core competitiveness of the NF150-300 thermal conductive pad lies in its outstanding thermal conductivity, reaching 3.0 W/m·K. This means it can efficiently transfer heat generated by heat sources (such as CPUs, GPUs, power modules, etc.) to heat sinks or structural components, effectively lowering the operating temperature of electronic components. For electronic devices that demand high performance and stability, this is undoubtedly the cornerstone for ensuring long-term stable operation.

2. Superior Electrical Insulation: Balancing Safety and Performance

In many applications, thermal interface materials must not only conduct heat but also possess good electrical insulation to prevent short circuits and leakage. The NF150-300 thermal conductive pad excels in this aspect, with a dielectric breakdown voltage of up to 6 kV/mm. Its high insulation strength ensures safe use in complex circuit environments, effectively preventing device failures due to electrical issues, allowing engineers to confidently apply it in critical locations during design.

3. Flexible Compressibility and Multi-Thickness Options: The "Perfect Partner" for Gap Filling

Electronic components often have uneven surfaces with tiny gaps. These gaps are filled with air, which is a poor thermal conductor and significantly hinders heat transfer efficiency. The NF150-300 thermal conductive pad boasts excellent flexibility and compressibility, with a hardness ranging from Shore C 20-60. It can effectively fill these irregular gaps, expel air, and achieve intimate contact between the heat source and the heat sink, maximizing heat transfer efficiency. Furthermore, its wide range of thicknesses, from 0.3mm to 20mm, offers great flexibility for various applications, ensuring a suitable specification for anything from miniature chip cooling to large power modules.

4. High Reliability and Stability: A Versatile Performer in Harsh Environments

Electronic products often operate in complex and variable environments, demanding high reliability from materials. The NF150-300 thermal conductive pad possesses excellent temperature resistance, capable of stable operation across a wide range from -40℃ to 180℃. Moreover, it has undergone rigorous testing, including high temperature and high humidity (85℃/85%RH), thermal shock, and long-term aging tests, proving its ability to maintain its physical and chemical properties over extended periods in extreme temperatures, humidity, and other harsh conditions. This ensures the long-term stable operation of electronic devices, significantly reducing maintenance costs and failure risks.

5. Strong Processing Adaptability: Facilitating Assembly and Mass Production

The NF150-300 thermal conductive pad in processing and application demonstrates strong adaptability. It supports various structural customizations, including double-sided adhesive, PI film, and fiberglass cloth backings. This not only enhances the material's structural strength but also greatly facilitates automated pick-and-place processes, boosting production efficiency. At the same time, its excellent dimensional stability means it's less prone to deformation or displacement during assembly, making it suitable for complex assembly scenarios. This effectively improves production efficiency and significantly reduces the risk of yield loss due to material issues, providing a solid guarantee for mass production.

6. Environmental Friendliness and Safety: Aligning with Future Trends

In an era of increasing environmental awareness, the environmental friendliness of materials has also become an important criterion for evaluating their value. The NF150-300 thermal conductive pad typically complies with environmental directives such as RoHS, containing no harmful substances and posing no threat to human health or the environment. This makes it more competitive in terms of green manufacturing and sustainable development.

Application Scenarios: Where Does the NF150-300 Thermal Conductive Pad Excel?

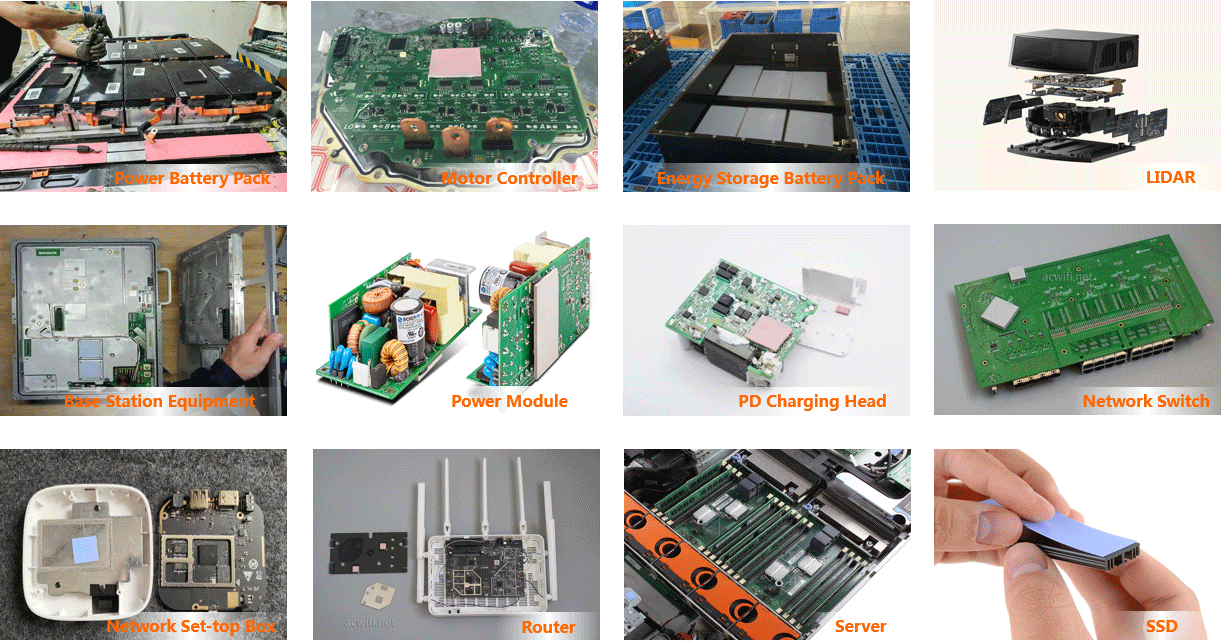

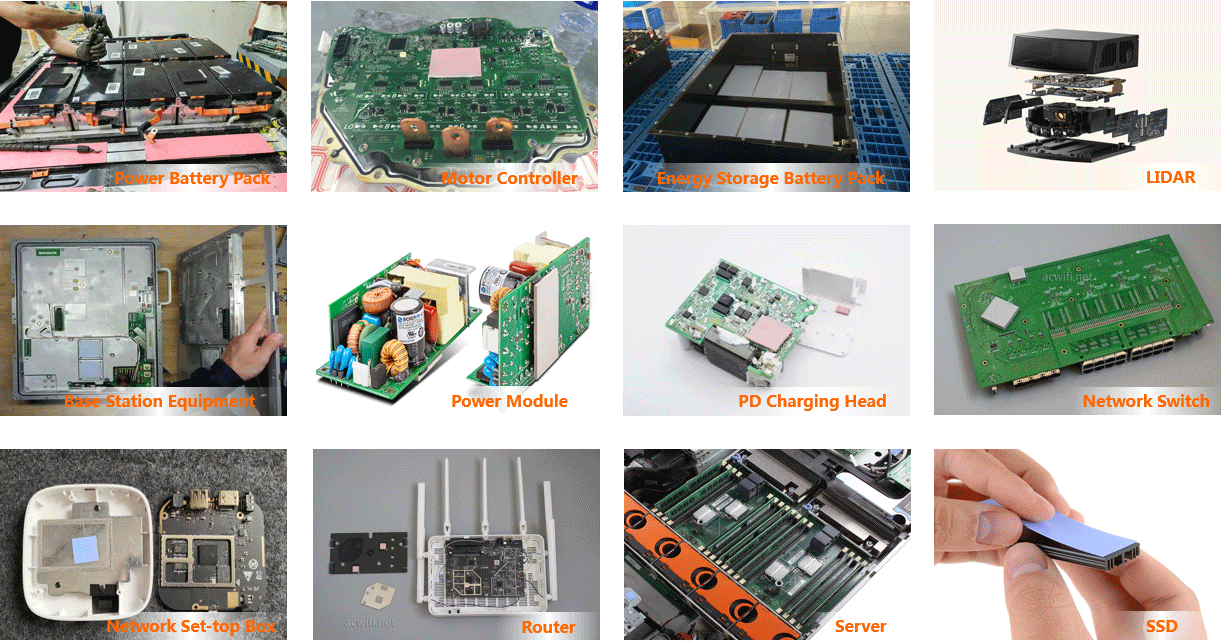

Thanks to its comprehensively excellent performance, the NF150-300 thermal conductive pad finds its use in numerous fields:

▪ Consumer Electronics: Laptops, tablets, smartphones, smart wearables, etc., effectively solving heat dissipation issues for heat-generating components like CPUs, GPUs, and batteries.

▪ Communication Equipment: Routers, switches, base stations, etc., ensuring stable operation of critical components like power modules and RF modules.

▪ Artificial Intelligence Devices: Robots, robot dogs, and other high-performance computing units and motor drive systems, ensuring the stability of complex calculations and motion control.

▪ Automotive Electronics: Power batteries, in-car infotainment systems, ADAS systems, etc., coping with complex conditions like high temperatures and vibrations.

▪ LED Lighting: Driver power supplies, LED chip heat dissipation, etc., extending the service life and luminous efficacy of LED lamps.

▪ Beauty Products: Beauty devices, radiofrequency instruments, and other personal care devices requiring precise temperature control and stable operation, enhancing user experience and safety.

▪ Industrial Control and Medical Equipment: Ensuring the long-term stable operation of various precision instruments.

Conclusion: Choose NF150-300, Choose a Reliable Thermal Management Solution

In summary, the NF150-300 thermal conductive pad, with its thermal conductivity of up to 3.0 W/m·K, electrical insulation up to 6 kV/mm dielectric breakdown voltage, multi-thickness options from 0.3mm to 20mm, Shore C 20-60 flexibility, wide temperature range of -40℃ to 180℃, and excellent stability and reliability proven through rigorous testing, coupled with its outstanding processing adaptability, has become an indispensable component in the field of electronic thermal management. It is not merely a thermal interface material but a crucial guarantee for the stable operation and performance optimization of electronic devices.

When selecting thermal interface materials, in addition to thermal conductivity, it's essential to comprehensively consider their overall performance and choose based on actual application requirements. If you're seeking an efficient and reliable solution for heat dissipation in electronic devices, the NF150-300 thermal conductive pad is undoubtedly an excellent option worth considering.

CN >

CN >