In high-tech fields like 5G communication, radar stealth, and electromagnetic compatibility, thermal conductive absorbing materials are playing an increasingly vital role. These materials integrate electromagnetic wave absorption and thermal management functions, effectively solving the problems of overheating and electromagnetic interference in electronic devices in complex electromagnetic environments. However, as their applications become more widespread, a core question arises: Are thermal conductive absorbing materials actually toxic? This is not only a focus for researchers and engineers but also a question on the minds of ordinary consumers when using related products. This article will deeply analyze the composition, working mechanism, and potential toxicity of thermal conductive absorbing materials, revealing the safety truth behind this cutting-edge technology.

The "True Colors" of Thermal Conductive Absorbing Materials: Composition and Principles

To discuss the toxicity of thermal conductive absorbing materials, we first need to understand what components they are made of and how they work together.

Core Component Analysis

Thermal conductive absorbing materials are typically composite materials, mainly composed of the following types of substances:

Absorbing Fillers: These are key to the material's ability to absorb electromagnetic waves. Common absorbing fillers include ferrites (e.g., NiZn ferrite, MnZn ferrite), carbonyl iron powder, carbon-based materials (e.g., carbon nanotubes, graphene), conductive polymers, and MXenes. They absorb electromagnetic waves through mechanisms such as magnetic loss, dielectric loss, or impedance matching.

Thermal Conductive Fillers: These provide the material with excellent thermal conductivity. Typical thermal conductive fillers include aluminum oxide (Al₂O₃), boron nitride (BN), zinc oxide (ZnO), silicon carbide (SiC), as well as silver powder and copper powder. These materials have high thermal conductivity and can efficiently transfer heat generated by equipment.

Matrix Materials (Polymer-based): Absorbing fillers and thermal conductive fillers are usually dispersed in a polymer matrix, such as silicone rubber, epoxy resin, polyurethane, etc. The polymer matrix not only provides structural support and formability but also adjusts the material's flexibility, weather resistance, and other properties.

The Double Magic of "Absorption + Thermal Conduction"

The working principle of thermal conductive absorbing materials can be simply summarized as "absorbing electromagnetic energy, conducting thermal energy":

Electromagnetic Wave Absorption: When electromagnetic waves hit the material's surface, the magnetic domains or electric dipoles within the absorbing fillers polarize or magnetize under the action of the electromagnetic field, thereby converting electromagnetic energy into heat or other forms of energy for dissipation, achieving the effect of absorbing electromagnetic waves.

Heat Conduction: At the same time, the thermal conductive fillers in the material build an efficient thermal conduction network, rapidly transferring the heat generated by electromagnetic wave absorption and the heat generated by the device itself, preventing localized overheating.

Toxicity Considerations for Thermal Conductive Absorbing Materials: Angel or Devil?

Back to the core question: Are thermal conductive absorbing materials toxic? The answer is not a simple "yes" or "no"; it depends on the specific material composition, production process, application environment, and exposure method.

Potential "Hidden Dangers": High-Risk Component Analysis

Although many thermal conductive absorbing materials are non-toxic or low-toxic, some components do pose potential health risks:

Heavy Metals and Their Compounds: Some absorbing fillers, such as nickel (Ni), cobalt (Co) and their oxides, as well as some heavy metal salts, may be sensitizing, carcinogenic, or reproductive toxicants under specific conditions. For example, nickel is a common allergen, and long-term or high-concentration contact can cause dermatitis.

Nanomaterials: Nanoscale absorbing fillers such as carbon nanotubes, graphene, and nanometal oxides, due to their extremely small size, may more easily enter human cells, causing inflammatory reactions, lung damage, etc. Although research on the long-term effects of nanomaterials on the human body is still ongoing, potential risks cannot be ignored.

Volatile Organic Compounds (VOCs): During the production, processing, or aging of materials, the matrix polymer or additives may release small amounts of VOCs, such as formaldehyde, benzene series, etc. These VOCs may cause irritation or damage to the respiratory tract, skin, and nervous system.

Inhalable Dust: During the preparation and processing of materials, if protective measures are inadequate, fine dust from absorbing fillers or thermal conductive fillers may be inhaled into the respiratory tract, leading to pneumoconiosis or other respiratory diseases.

Safety "Guarantee": Low-Risk Components and Encapsulated Applications

Fortunately, most commercially available thermal conductive absorbing materials are designed and produced with full consideration for safety. Many common material components themselves have low toxicity, and effective protective measures are taken in practical applications:

Non-toxic or Low-toxic Components: Many high-performance thermal conductive absorbing materials use aluminum oxide, boron nitride, silicone rubber, and other intrinsically low-toxicity materials as main components, greatly reducing potential risks.

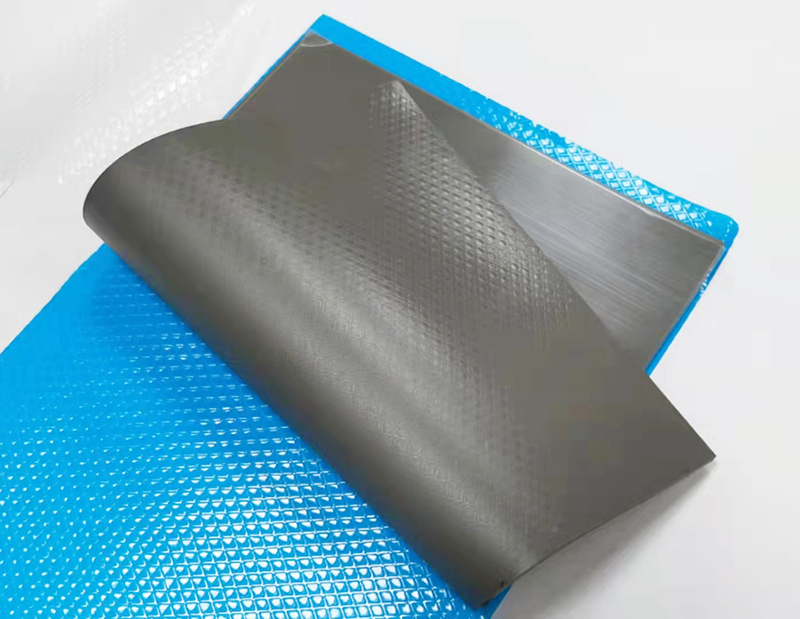

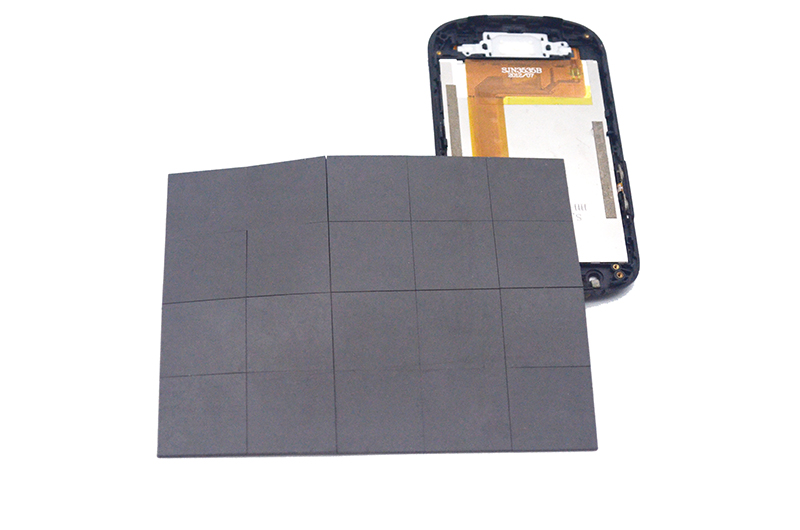

Solid Encapsulation: Thermal conductive absorbing materials are usually applied in electronic devices in solid form (e.g., sheets, gels, coatings), which means that the active components are firmly encapsulated by the matrix material and are not easily leaked or volatilized. Under normal use conditions, consumers will hardly directly contact these internal materials.

Professional Treatment and Protection: For enterprises that produce and process thermal conductive absorbing materials, national and industry standards have strict safety production regulations. Workers need to wear professional protective equipment (such as masks, gloves, protective clothing) and operate in well-ventilated environments to minimize exposure risks.

Compliance with Regulatory Standards: Compliant thermal conductive absorbing material products need to meet international environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which have strict limits on the content of harmful substances in materials.

Conclusion and Outlook: Safe Use, Technology for Good

In summary, whether thermal conductive absorbing materials themselves are toxic is a complex question with no blanket answer. Some components, especially heavy metals and nanomaterials, do pose potential health risks. However, at the same time, the research and development trend of modern thermal conductive absorbing materials is to use more environmentally friendly and safer components, and in practical applications, the materials are usually effectively encapsulated in solid form, greatly reducing the possibility of ordinary users coming into contact with harmful substances.

For consumers, there is no need to panic about the term "thermal conductive absorbing materials." As long as you purchase products from reputable brands that comply with industry standards and use them correctly according to the instructions, their safety can be guaranteed. The real concerns lie in the production process and waste disposal of these materials, which require joint efforts from the industry and regulatory bodies to ensure compliance with environmental and safety regulations from source to end.

In the future, with the continuous advancement of technology, we expect thermal conductive absorbing materials to continue to develop towards "higher efficiency, thinner, more environmentally friendly, and safer" directions. Researchers will constantly explore new non-toxic and harmless absorbing and thermal conductive components, and optimize preparation processes, striving to achieve excellent performance while minimizing potential impacts on the environment and human health, truly allowing technology to better serve human life.

CN >

CN >