In today's highly electronic era, electromagnetic compatibility (EMC) and thermal management are two major challenges in electronic device design. Thermally conductive electromagnetic wave absorbing materials, as an innovative solution, are gaining increasing attention. They can not only effectively absorb electromagnetic waves, reducing electromagnetic interference (EMI), but also efficiently conduct heat, solving device cooling problems. So, what exactly are thermally conductive electromagnetic wave absorbing materials? How do they work, what are their unique properties, and where are they applied?

The "Dual Mission" of Thermally Conductive Electromagnetic Wave Absorbing Materials: Unveiling the Principles

Thermally conductive electromagnetic wave absorbing materials, as the name suggests, are composite materials that integrate both electromagnetic wave absorption and heat conduction functions. Their "dual mission" is primarily achieved through the special components within the material and their synergistic effects.

Wave Absorption Principle: The "Black Hole" of Electromagnetic Energy

The core of wave absorption lies in the material's ability to dissipate electromagnetic wave energy. This is typically achieved through the following mechanisms:

▪ Dielectric Loss: Polar molecules or defects within the material polarize under the action of an electromagnetic field and continuously reorient with the alternating electromagnetic field. The friction and relaxation processes between molecules convert electromagnetic energy into heat.

▪ Magnetic Loss: Magnetic particles (such as ferrites, carbonyl iron powder, etc.) introduced into the material experience hysteresis loss, eddy current loss, and resonance loss under the action of an electromagnetic field, also converting electromagnetic energy into heat.

▪ Structural Loss: Through the design of the material's microscopic structure, such as porous structures, gradient structures, or chiral structures, the propagation path of electromagnetic waves within the material can be extended, increasing their interaction time with the material, thereby improving absorption efficiency.

Through these mechanisms, the electromagnetic wave energy entering the material is effectively "captured" and converted into heat, thus achieving the goal of absorbing electromagnetic waves.

Heat Conduction Principle: The Efficient Heat "Transporter"

Heat conduction, on the other hand, primarily relies on the construction of highly thermally conductive components within the material. These components typically include:

▪ Thermally Conductive Fillers: Such as boron nitride (BN), aluminum oxide (Al2O3), silicon nitride (Si3N4), and carbon-based materials (graphite, graphene, carbon nanotubes, etc.). These materials themselves have excellent thermal conductivity, and by forming a thermally conductive network within the matrix material, they can significantly increase the overall thermal conductivity of the composite material.

▪ Continuous Phase Matrix: Such as silicone rubber, epoxy resin, and other polymer materials, which serve as a continuous phase connecting the thermally conductive fillers and providing necessary mechanical properties.

Heat is rapidly transferred from the heat source to the heat sink through direct contact between filler particles, phonon transport between fillers and the matrix, and the matrix's own thermal conductivity.

Unique Advantages: The "Hardcore" Properties of Thermally Conductive Electromagnetic Wave Absorbing Materials

Thermally conductive electromagnetic wave absorbing materials are highly favored due to their series of unique and excellent properties:

▪ Multifunctional Integration: This is their most significant advantage, combining wave absorption and heat conduction functions, simplifying the integration scheme of electronic devices, and reducing the number of components and space occupation.

▪ Excellent Electromagnetic Compatibility: They can effectively suppress electromagnetic radiation generated by electronic devices, reduce electromagnetic interference, and improve device stability and reliability. This is particularly important in high-frequency communication fields such as 5G and IoT.

▪ Efficient Thermal Management Capability: Even when electromagnetic waves are absorbed and converted into heat, they can quickly conduct this heat away, preventing localized overheating and protecting sensitive electronic components.

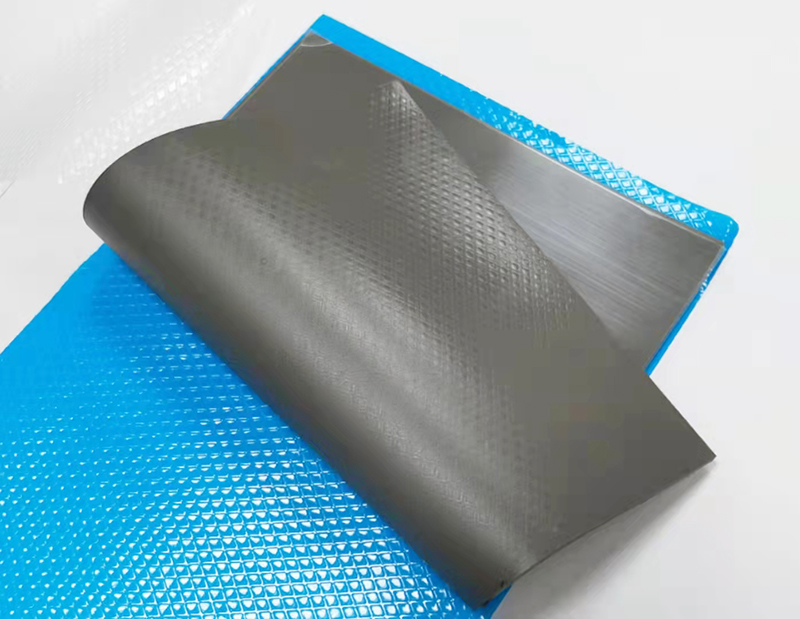

▪ Thin and Lightweight Design: Compared to traditional absorbing materials and cooling solutions, thermally conductive electromagnetic wave absorbing materials often achieve thinner and lighter designs, meeting the demands for miniaturization and portability in modern electronic products.

▪ Strong Designability: By adjusting the material's composition, structure, and preparation process, its absorption frequency, absorption efficiency, and thermal conductivity can be flexibly controlled to meet the specific requirements of different application scenarios.

▪ Good Environmental Resistance: Most thermally conductive electromagnetic wave absorbing materials have good resistance to high temperatures, heat and humidity, and corrosion, adapting to complex and harsh working environments.

Broad Prospects: Innovative Applications of Thermally Conductive Electromagnetic Wave Absorbing Materials

With their unique combination of properties, thermally conductive electromagnetic wave absorbing materials demonstrate immense application potential across numerous fields.

▪ Communication Electronic Devices: In smartphones, tablets, base stations, routers, and other products, thermally conductive electromagnetic wave absorbing materials can be used to shield electromagnetic radiation generated by high-frequency components such as processors and RF modules, while simultaneously solving their heat dissipation problems, ensuring stable device operation and compliance with EMC standards. Especially in the 5G era, the application of high-frequency bands makes electromagnetic interference and heat dissipation issues more prominent, where thermally conductive electromagnetic wave absorbing materials will play a crucial role.

▪ Automotive Electronics: With the development of autonomous driving, in-car infotainment systems, and other technologies, the number of electronic devices inside cars has increased dramatically, making electromagnetic interference and heat dissipation new challenges. Thermally conductive electromagnetic wave absorbing materials can be used in automotive radar, sensors, controllers, and other modules to improve system reliability.

▪ Aerospace: High-precision electronic equipment inside aircraft requires extremely high electromagnetic compatibility. Thermally conductive electromagnetic wave absorbing materials can provide efficient electromagnetic protection and thermal management for radomes, antennas, and communication systems, enhancing the overall performance and safety of aircraft.

▪ Wearable Devices and Medical Devices: These devices are usually compact and highly integrated, with strict requirements for heat dissipation and electromagnetic compatibility. Thermally conductive electromagnetic wave absorbing materials can be applied to smartwatches, hearing aids, implantable medical devices, etc., ensuring their normal operation and reducing electromagnetic effects on the human body.

▪ Military and Defense: In fields such as stealth technology, radar countermeasures, and electronic warfare, the application of thermally conductive electromagnetic wave absorbing materials can effectively reduce the detectability of equipment, improving the survivability and combat effectiveness of weapons and equipment.

▪ Data Centers and Servers: Large-scale data centers generate enormous amounts of heat and electromagnetic radiation. Thermally conductive electromagnetic wave absorbing materials can be used in server chassis, PCB boards, etc., to improve heat dissipation efficiency and reduce electromagnetic crosstalk between devices.

Conclusion: Material Science for the Future

Thermally conductive electromagnetic wave absorbing materials represent an important development direction in material science and engineering. With their unique "absorption + conduction" integrated function, they offer an innovative solution to the dual challenges of electromagnetic compatibility and thermal management faced by modern electronic devices. As technology continues to advance, and material performance requirements become increasingly stringent, we have reason to believe that thermally conductive electromagnetic wave absorbing materials will play an increasingly vital role in future high-tech fields such as electronics, communication, automotive, and aerospace, contributing to our intelligent lives and national security.

What are your expectations for the future development of thermally conductive electromagnetic wave absorbing materials? Or do you think they will have breakthrough applications in new areas?

CN >

CN >