In electronic devices and industrial applications, the choice of thermal interface materials plays a crucial role in heat dissipation. Mica sheets and silicone sheets are two commonly used thermal materials, each with unique physical properties and thermal conductivity performance. NFION will provide a detailed comparison of the thermal performance of these two materials, discuss their application scenarios, and highlight their advantages, helping engineers and procurement professionals make informed decisions.

Thermal Conductivity and Characteristics of Mica Sheets

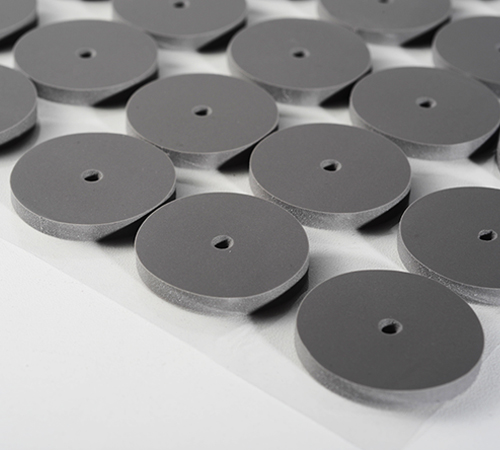

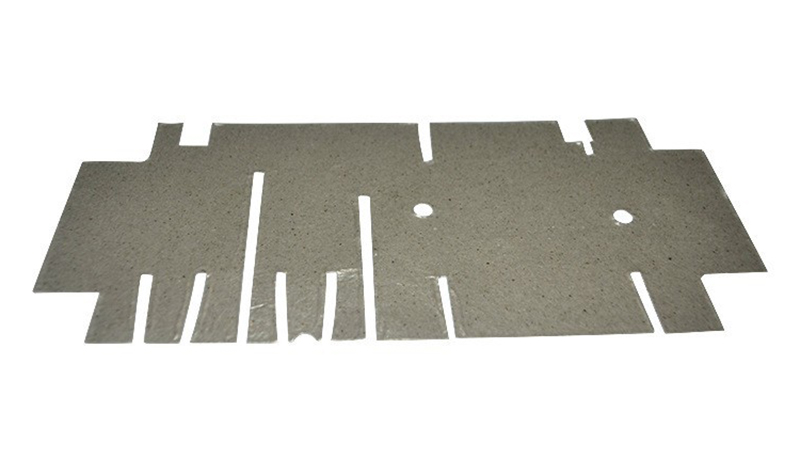

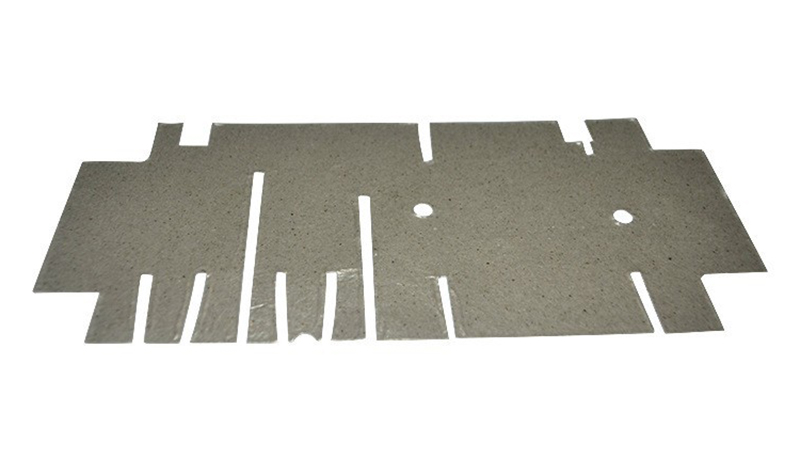

Mica sheets are a type of natural mineral material with a unique layered structure and excellent insulation properties. They are widely used in electronic and electrical equipment.

1. Thermal Conductivity

Mica sheets have relatively low thermal conductivity, typically ranging from 0.3 to 0.5 W/m·K. Although this thermal conductivity is not comparable to high-performance materials such as aluminum and copper, mica sheets can still help dissipate heat to some extent, making them suitable for applications that do not require high thermal conductivity but demand electrical insulation.

2. Insulation Properties

Mica sheets have excellent insulation properties, with voltage withstand capabilities of several thousand volts. They maintain stable insulation performance even in high-temperature environments (up to 500°C), which makes them widely used in high-voltage equipment.

3. Heat Resistance and Stability

Mica sheets are highly stable in high-temperature environments and are not prone to decomposition or aging. They are suitable for harsh operating conditions, such as electric motors, transformers, and high-temperature furnace components. Their durability under extreme conditions makes mica sheets an important choice in electrical and industrial applications.

Thermal Conductivity and Characteristics of Silicone Sheets

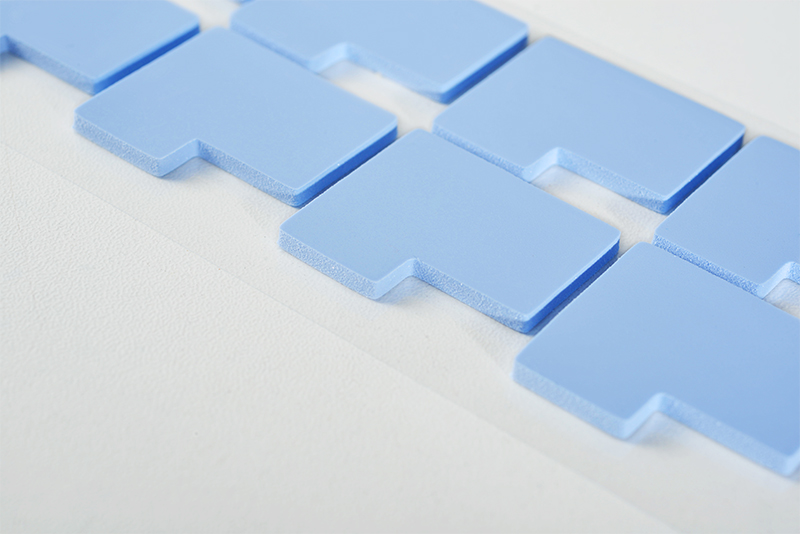

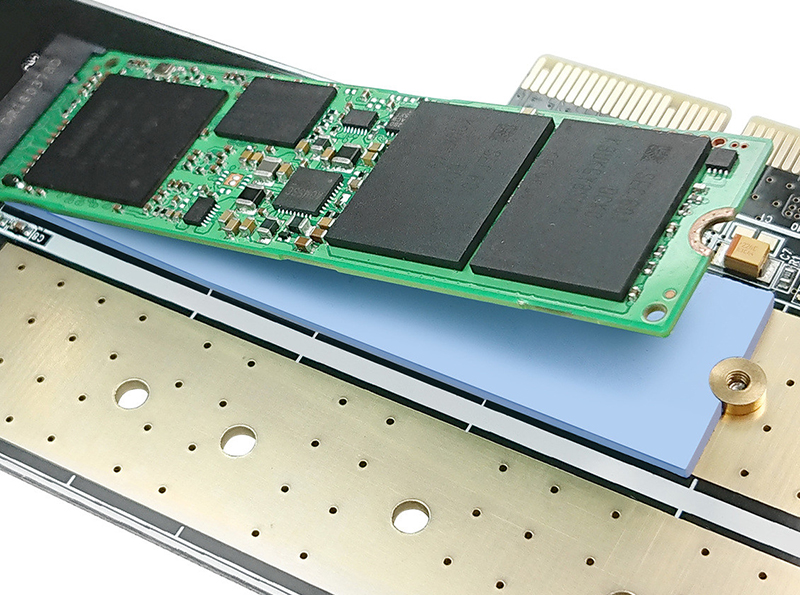

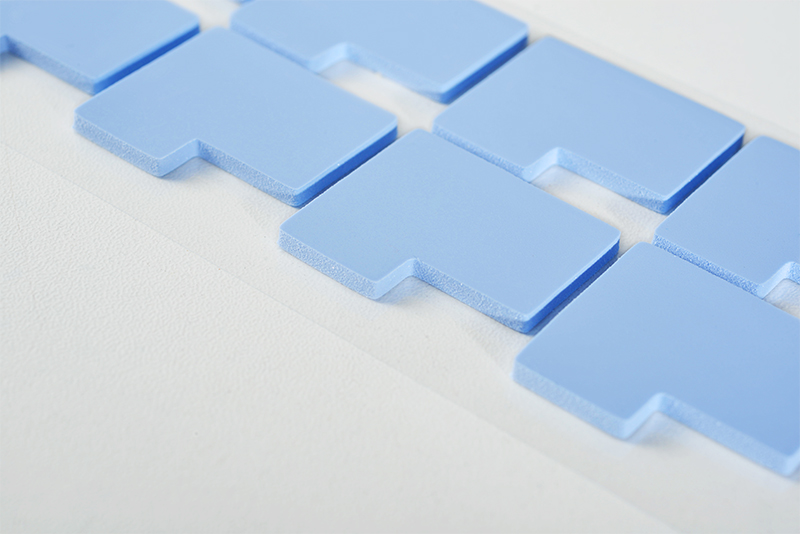

Silicone sheets are flexible thermal materials made from a silicone base and thermal conductive fillers. Due to their excellent thermal conductivity and adaptability, silicone sheets have found wide applications in both electronic and industrial fields.

1. Thermal Conductivity

The thermal conductivity of silicone sheets typically ranges from 1.0 to 10.0 W/m·K, which is significantly higher than that of mica sheets. With advancements in technology, the thermal conductivity of silicone sheets continues to improve, reaching over 12.0 W/m·K in some cases. This makes silicone sheets very popular for high-power electronic devices that require rapid heat dissipation.

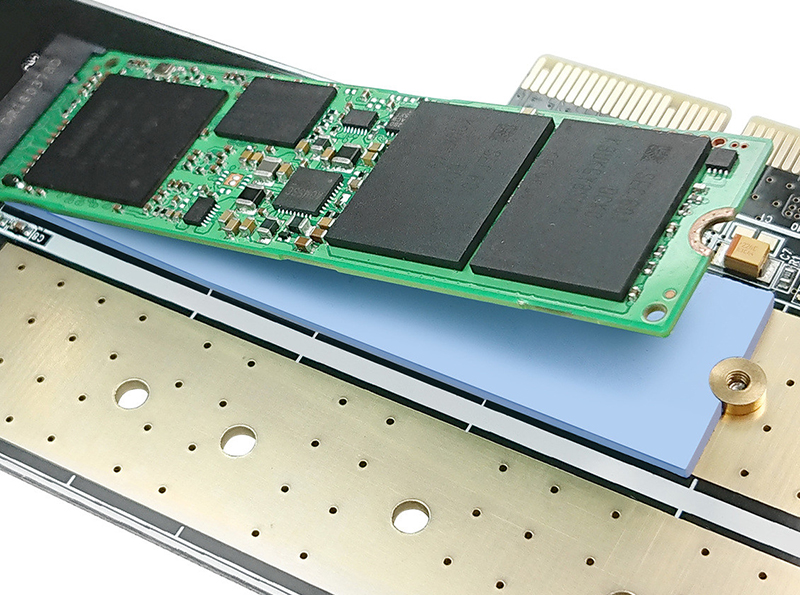

2. Flexibility and Gap-Filling Ability

Silicone sheets exhibit excellent flexibility, enabling them to adapt to complex contact surfaces, fill small gaps, and increase contact area, thereby reducing thermal resistance. This characteristic makes silicone sheets particularly useful in irregular or gap-filled structures, significantly improving heat dissipation efficiency.

3. Electrical Insulation Properties

Silicone sheets also possess good insulation properties, typically withstanding voltages ranging from hundreds to thousands of volts. They are ideal for applications that require both high thermal conductivity and electrical insulation.

4. Durability and Stability

While silicone sheets do not have the same high-temperature resistance as mica sheets, they still perform well in the common temperature range of electronic devices (-40°C to 200°C). With modern additives and optimized formulations, the durability of silicone sheets has been improved, enhancing their aging resistance and ensuring long service life even in high-temperature and harsh environments.

Application Scenarios Comparison: Mica Sheets vs Silicone Sheets

1. Typical Applications of Mica Sheets

Mica sheets are mainly used in scenarios that require high electrical insulation but not necessarily high thermal conductivity. Typical applications include high-voltage electrical equipment, motor insulation components, and transformers, where electrical insulation and stability in high-temperature environments are critical.

2. Typical Applications of Silicone Sheets

Silicone sheets are widely used in various electronic devices and power electronics modules, such as CPU and GPU heat sinks, power modules, and LED lighting. They provide efficient heat dissipation while ensuring electrical insulation, making them ideal for high-power and high-temperature applications. Silicone sheets are particularly useful in consumer electronics, such as smartphones and tablets, where efficient thermal management is essential to prolong device life and maintain performance stability.

Comprehensive Thermal Conductivity Comparison

|

Property

|

Mica Sheet

|

Silicone Sheet

|

|

Thermal Conductivity

|

0.3~0.5 W/m·K

|

1.0~10.0 W/m·K and above

|

|

Insulation

|

Excellent

|

Good

|

|

Heat Resistance

|

High (up to 500℃)

|

Moderate (-40°C to 200°C)

|

|

Gap-Filling Ability

|

Poor

|

Excellent

|

|

Application

|

High-voltage insulation

|

Electronic heat dissipation

|

Conclusion

In terms of thermal conductivity, silicone sheets clearly outperform mica sheets, making them more suitable for applications that require rapid heat dissipation and higher thermal efficiency. However, mica sheets excel in high-voltage insulation and stability in extreme conditions, making them the preferred choice for applications that do not require high thermal conductivity but demand electrical insulation. Therefore, when choosing a thermal material, it is essential to balance the specific needs of the application. If high thermal dissipation and electrical isolation are required, silicone sheets are the better choice. Conversely, if high electrical insulation is necessary without significant thermal conductivity demands, mica sheets are more suitable.

CN >

CN >