Are Thermal Silicone Pads Insulating? How to Improve Electrical Isolation

Thermal silicone pads, as a common thermal management material, are widely used in electronic devices, LED lighting, computers, automotive electronics, and other fields. Their primary function is to transfer heat from the heat source to the heat sink through thermal conduction, helping to maintain the proper operating temperature of the device. However, in addition to thermal conductivity, the insulation properties of thermal silicone pads are also a crucial characteristic in many applications. So, are thermal silicone pads inherently insulating? And if their insulation strength is insufficient, how can we improve it?

NFION will delve into the insulation properties of thermal silicone pads and discuss several effective methods to enhance their insulation strength.

Basic Composition and Properties of Thermal Silicone Pads

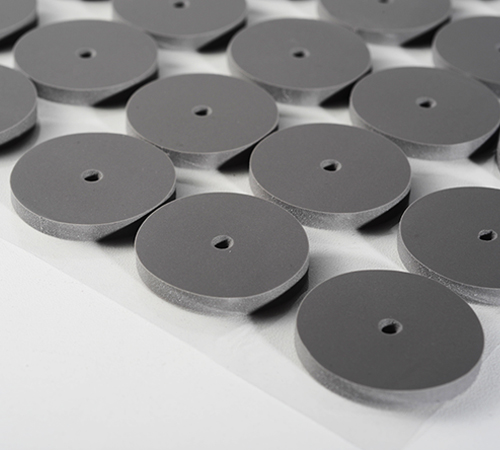

Thermal silicone pads are generally composed of a silicone base material and thermal conductive fillers (such as aluminum silicate, aluminum oxide, boron nitride, etc.). The silicone base material provides good flexibility and insulation properties, while the fillers enhance the thermal conductivity. Therefore, thermal silicone pads need to provide high thermal conductivity while ensuring electrical insulation to prevent electrical shorts and device failure.

The insulation properties of thermal silicone pads are typically manifested in their dielectric strength and electrical insulation characteristics. Dielectric strength refers to the maximum voltage a material can withstand without breaking down under specific conditions. The electrical insulation properties of thermal silicone pads primarily depend on the chemical structure of the silicone base material and the insulating properties of the fillers.

Electrical Insulation Properties of Thermal Silicone Pads

In most cases, thermal silicone pads possess a certain level of insulation in normal applications, but this property is not guaranteed under all conditions. In high-voltage, high-frequency, or special working environments, the insulation performance of thermal silicone pads may degrade due to material inhomogeneity or environmental factors (such as temperature and humidity).

Electrical Insulation of Thermal Silicone Pads

The electrical insulation of thermal silicone pads is influenced by multiple factors. First, the silicone rubber base material itself has good insulating properties, but if the thermal conductive filler is improperly chosen, it could affect the electrical isolation. For instance, using certain metal oxides or metal powders as fillers may reduce the insulation strength of thermal silicone pads. Therefore, the choice of fillers is an important factor affecting the electrical insulation of thermal silicone pads.

Impact of Temperature and Environmental Conditions

The insulation properties of thermal silicone pads can also be significantly affected by temperature and environmental conditions. At high temperatures, the insulating properties of the silicone base material may degrade due to thermal aging, especially with long-term exposure to elevated temperatures. Therefore, good thermal stability is crucial for maintaining the insulation performance of thermal silicone pads.

How to Improve the Insulation Strength of Thermal Silicone Pads?

Improving the insulation strength of thermal silicone pads is key to ensuring reliable operation in high-voltage, high-temperature, or complex electrical environments. The following methods can effectively improve the electrical insulation properties of thermal silicone pads.

Optimize the Choice of Fillers

Fillers directly influence both the thermal conductivity and insulation properties of thermal silicone pads. To enhance insulation strength, fillers with good electrical insulation properties, such as boron nitride and aluminum oxide, should be used. These materials not only have excellent thermal conductivity but also provide high electrical insulation. Avoiding fillers that contain conductive components, such as metal powders or graphite, can significantly improve the insulation strength of the silicone pad.

Use High-Quality Silicone Base Materials

The quality of the silicone base material determines the fundamental electrical insulation performance of the thermal silicone pad. Choosing high-purity, low-volatility, and thermally stable silicones can reduce the degradation of insulation properties caused by material aging or contamination. Additionally, the thickness of the silicone base material also affects its insulation performance; appropriately increasing the base material thickness can further enhance insulation strength.

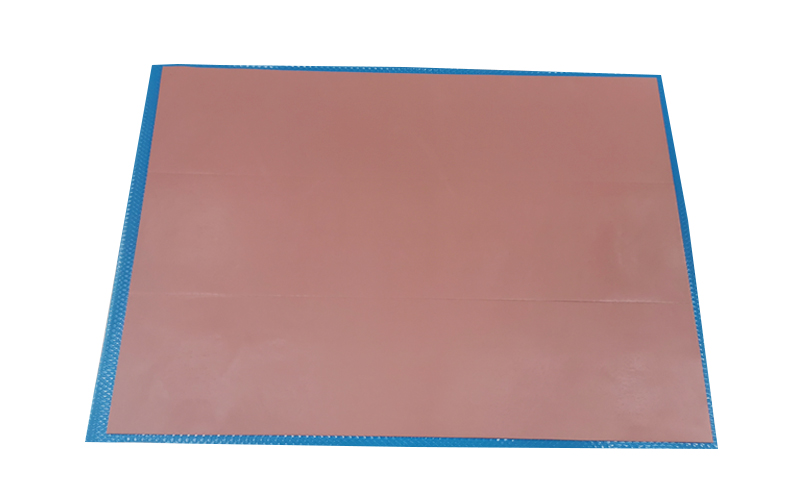

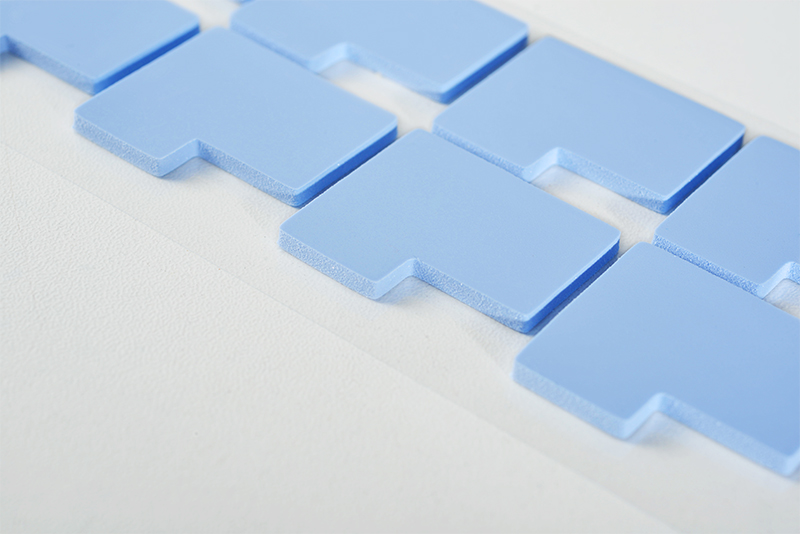

In addition to silicone itself, fiberglass cloth is often used as a reinforcing material in thermal silicone pads. Fiberglass cloth offers excellent mechanical strength, thermal stability, and inherent electrical insulation properties. When combined with silicone, fiberglass can effectively improve the pad's compressive strength, high-temperature resistance, and aging resistance. Moreover, the addition of fiberglass cloth enhances the material's structural stability, especially in high-temperature environments, preventing deformation or performance degradation due to thermal expansion.

One of the key advantages of fiberglass cloth as a substrate is its high dielectric strength and resistance to electrical breakdown, providing stronger electrical isolation. As a result, thermal silicone pads with fiberglass cloth as the base material exhibit enhanced stability and reliability, especially in high-voltage environments.

Control the Moisture Content During Production

Moisture is a significant factor that can reduce insulation performance. During the production of thermal silicone pads, controlling the moisture content is critical. Moisture can decrease the breakdown strength of the silicone pad, potentially causing electrical shorts. Therefore, maintaining a dry production environment and employing low-humidity processes can significantly improve the insulation performance of the thermal silicone pads.

Improve Surface Treatment Technology

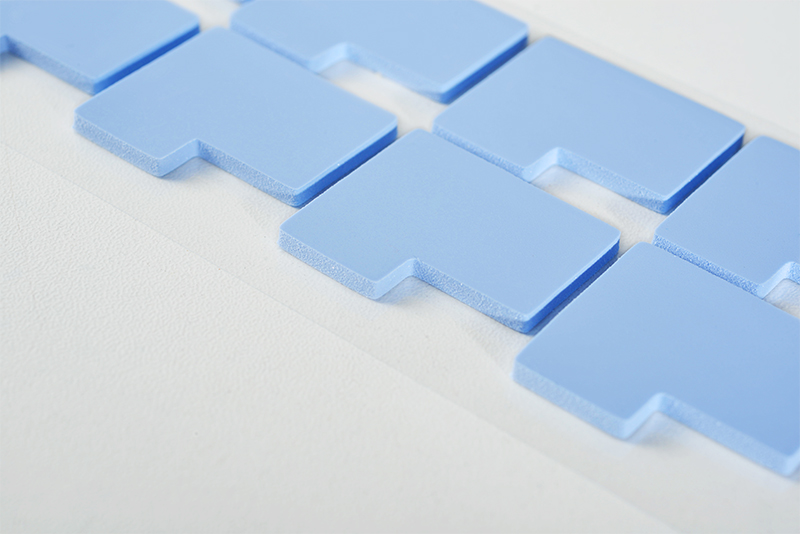

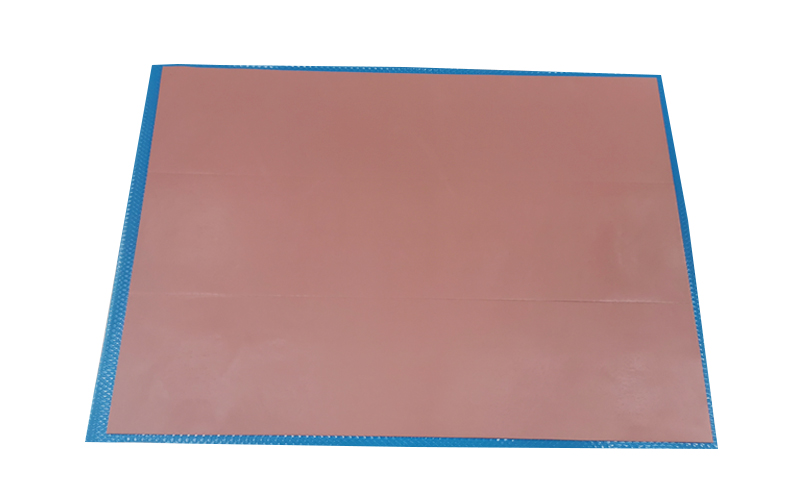

The surface treatment process of thermal silicone pads also plays an essential role in their insulation properties. By optimizing the smoothness and uniformity of the silicone surface and reducing surface irregularities, local high-voltage concentrations can be avoided, reducing the risk of breakdown. In addition, applying surface coatings or additional insulation layers, such as laminated insulation sheets and polyimide (PI) films, can significantly improve electrical isolation.

Laminated insulation sheets, typically made from materials like polyimide films and PET films, can be directly applied to the surface of thermal silicone pads, providing an additional insulating barrier. This layer not only enhances the electrical isolation but also improves the temperature resistance and mechanical strength, making it especially suitable for applications that require both excellent thermal conductivity and high insulation performance.

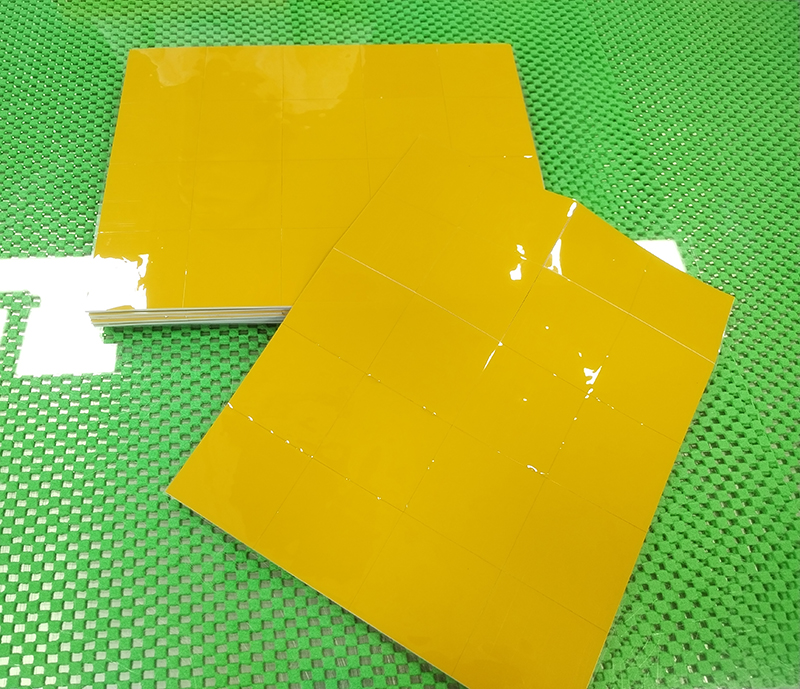

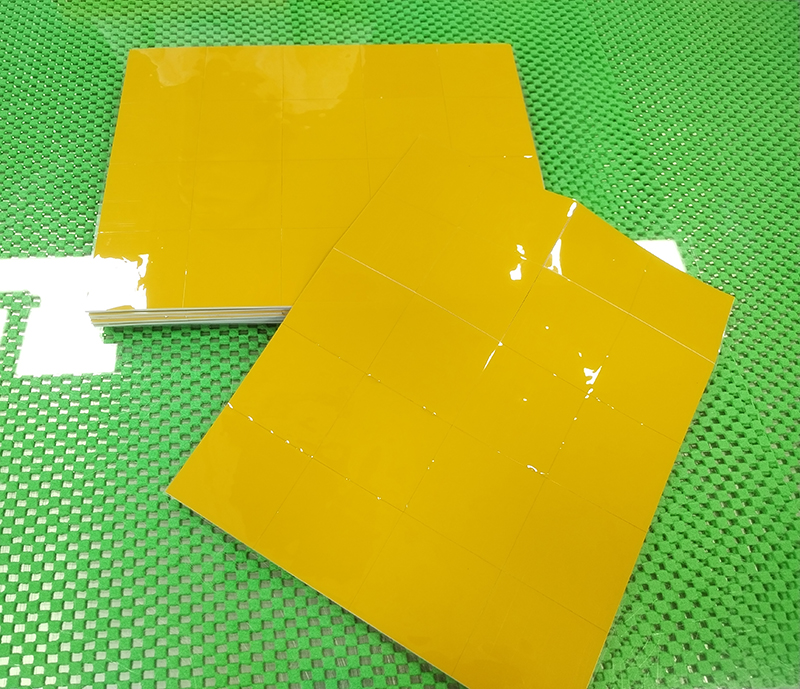

Polyimide (PI) film, known for its excellent electrical insulation, high-temperature resistance, and chemical stability, can be used as a cover or interlayer in thermal silicone pads to further improve insulation strength. The high thermal stability of PI film makes it ideal for long-term use in electronic devices, as it does not easily degrade or lose performance. Adding PI film to the surface of thermal silicone pads effectively enhances insulation performance in high-voltage and high-temperature environments, ensuring the safety and stability of the device.

Improve Thermal Stability

Thermal stability is closely related to insulation performance. At high temperatures, material thermal aging and oxidation reactions can degrade insulation properties. Therefore, selecting raw materials with high-temperature stability and adopting appropriate crosslinking processes can improve the thermal stability of thermal silicone pads, thereby enhancing their insulation performance.

Conclusion

Thermal silicone pads are essential thermal management materials, and their insulation properties are equally critical in many applications. Although thermal silicone pads inherently possess a certain level of electrical insulation, their performance may degrade under specific conditions, especially in high-temperature and high-voltage environments. By optimizing the choice of fillers, improving production processes, and enhancing thermal stability, the insulation strength of thermal silicone pads can be significantly improved, ensuring reliable thermal management and electrical isolation in complex working environments.

CN >

CN >