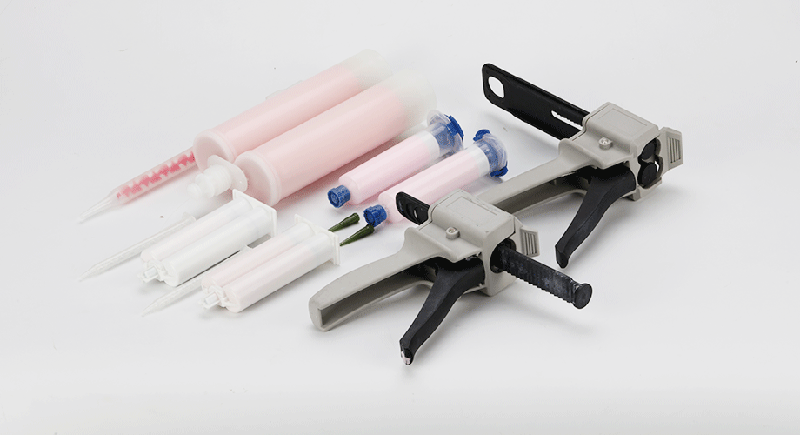

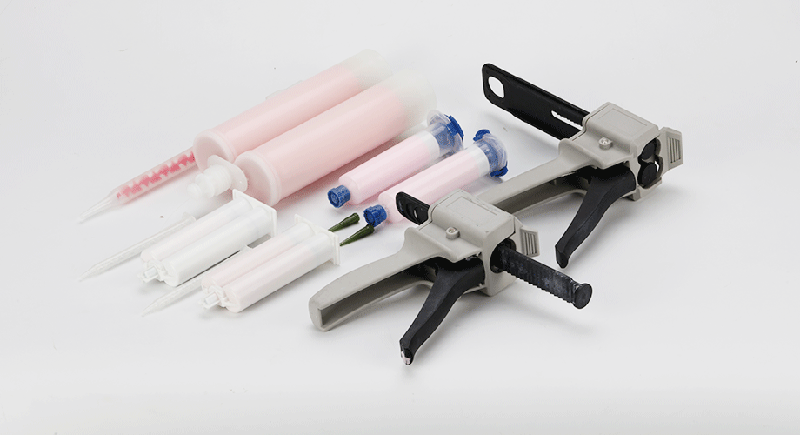

Thermal conductive gel, also known as thermal paste or thermal silicone, is a highly thermally conductive viscous substance widely used in thermal management systems of electronic devices. The primary function of thermal conductive gel is to fill the gaps between heat sinks and heat sources, improving thermal conductivity, ensuring stable temperature during device operation, enhancing performance, and extending lifespan.

Composition and Working Principle of Thermal Conductive Gel

Thermal conductive gel typically consists of three parts: thermally conductive fillers, matrix materials, and additives. Common thermally conductive fillers include aluminum oxide, boron nitride, and carbon fiber, which have high thermal conductivity. Matrix materials are usually silicone oil or organic silicon resin, known for their stability and adhesiveness. Additives adjust the gel’s viscosity, fluidity, and stability.

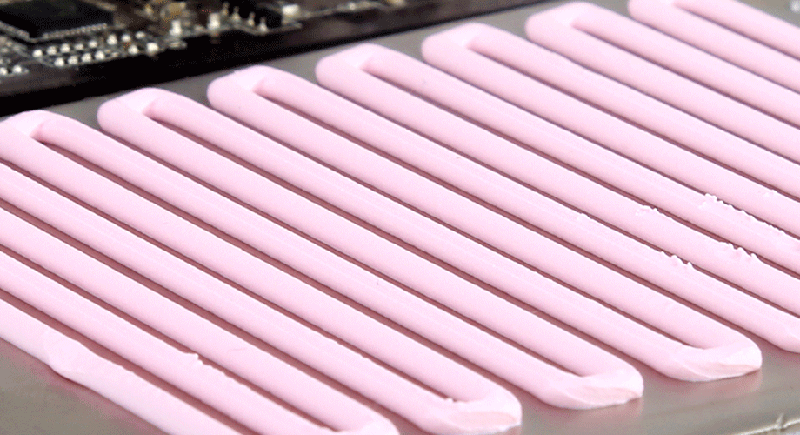

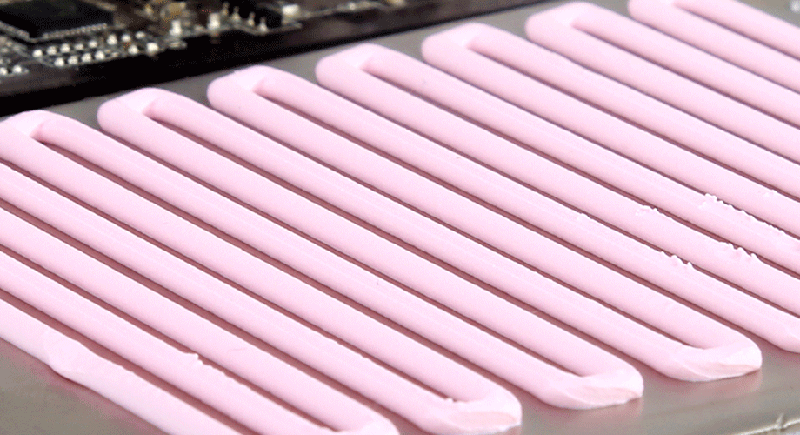

The working principle of thermal conductive gel is to fill the microscopic gaps between electronic components and heat sinks, expelling air, which is a poor thermal conductor. This creates a continuous thermal pathway, significantly enhancing the efficiency of heat transfer from the heat source to the heat sink. Due to its viscous nature, the gel can effectively fill irregular surfaces, maximizing heat conduction.

Main Functions of Thermal Conductive Gel

Enhancing Thermal Conductivity

The primary function of thermal conductive gel is to enhance thermal conductivity. Electronic devices generate substantial heat during operation, which, if not dissipated promptly, can lead to overheating, affecting performance and causing damage. Thermal conductive gel efficiently transfers heat to the heat sink, effectively reducing component temperature and ensuring normal device operation.

Enhancing Device Stability and Reliability

Electronic components are highly sensitive to temperature variations. Excessive heat can lead to short circuits and component aging. Using thermal conductive gel ensures that components operate in a relatively stable temperature environment, preventing heat-induced failures, thereby enhancing device stability and reliability.

Extending Lifespan of Electronic Devices

Electronic devices exposed to high temperatures for extended periods have significantly shorter lifespans. By using thermal conductive gel, operating temperature can be effectively reduced, minimizing thermal stress on components, extending device lifespan, and reducing maintenance and replacement costs.

Reducing Noise

In some high-performance electronic devices, traditional air cooling methods can generate considerable noise. The application of thermal conductive gel improves heat dissipation efficiency, allowing for lower fan speeds while maintaining effective cooling, thus reducing operational noise.

Applications of Thermal Conductive Gel

Thermal conductive gel is widely used in various electronic devices requiring efficient heat dissipation. Here are some main application areas:

Computers and Servers

In computers and servers, high-performance components like processors and graphics cards generate substantial heat. Thermal conductive gel is extensively used in their cooling systems to ensure stable operation under high loads.

Communication Equipment

With the advancement of communication technology, the power consumption of base stations and other communication equipment continues to increase. Thermal conductive gel is increasingly important in these devices to improve heat dissipation efficiency and ensure reliability.

LED Lighting

LED lights generate heat during operation, which, if not dissipated, can affect brightness and lifespan. Thermal conductive gel can effectively enhance the heat dissipation performance of LED lights, extending their lifespan.

Automotive Electronics

Modern automobiles integrate numerous electronic components, such as onboard computers, sensors, and entertainment systems, which generate heat during operation. The application of thermal conductive gel in automotive electronics can enhance heat dissipation, ensuring stable operation in various environments.

Medical Electronics

Medical devices like CT machines, ultrasound equipment, and portable monitors require precise temperature control. Stable operating temperatures improve diagnostic accuracy and device lifespan. Thermal conductive gel can effectively improve heat dissipation in these devices, ensuring long-term stable operation.

Household Appliances

Household appliances such as air conditioners, refrigerators, and washing machines generate heat during operation. Using thermal conductive gel can enhance the heat dissipation efficiency of these appliances, improving performance and durability while reducing energy consumption.

Instruments and Meters

Precision instruments and measurement devices are highly sensitive to temperature changes. Using thermal conductive gel ensures these devices operate in a stable temperature environment, enhancing measurement accuracy and device stability.

Electrical and Electrical Equipment

Transformers, power supplies, charging stations, and other electrical and electrical equipment generate substantial heat during operation. The application of thermal conductive gel can effectively enhance heat dissipation, ensuring the safety and stability of the equipment.

New Energy

Solar cells, wind turbines, and other new energy equipment need to maintain efficient operation under various environmental conditions. The application of thermal conductive gel can enhance the heat dissipation performance of these devices, extending their lifespan and improving energy utilization efficiency.

Security Equipment

Surveillance cameras, alarms, and other security equipment need stable operating temperatures for long-term operation. Thermal conductive gel can effectively enhance the heat dissipation of these devices, ensuring their reliability and stability in various environments.

Consumer Electronics

High-performance consumer electronics such as smartphones, tablets, and gaming consoles generate substantial heat during operation. The use of thermal conductive gel can enhance the heat dissipation efficiency of these products, improving performance and user experience.

Conclusion

As an efficient thermal material, thermal conductive gel plays a crucial role in modern electronic devices. It not only enhances thermal conductivity, ensuring device stability and reliability, but also extends device lifespan and reduces noise. With the continuous improvement in electronic device performance, the application of thermal conductive gel will become increasingly widespread, and its importance will become more prominent. When choosing and using thermal conductive gel, appropriate thermal materials and formulations should be selected based on specific application needs to achieve optimal cooling effects.

CN >

CN >