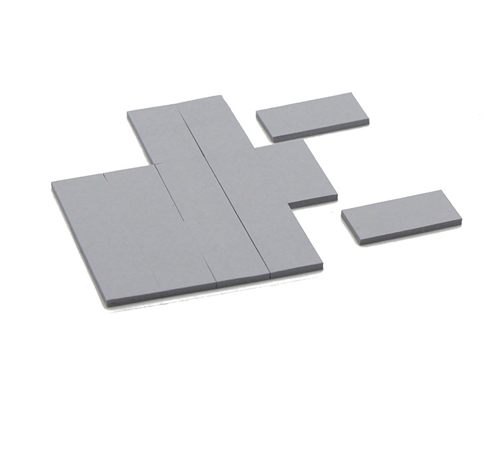

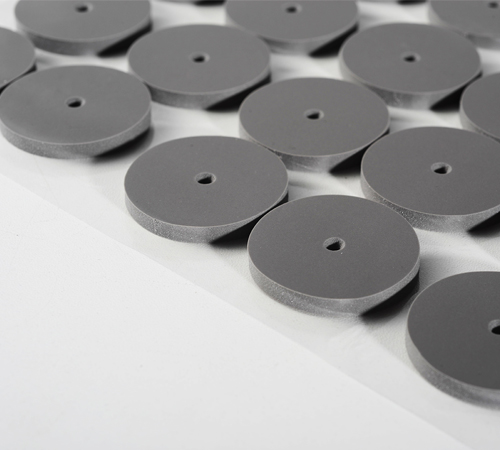

Thermal conductive pads are a prevalent thermal management material, widely used in electronics, electrical engineering, and heat dissipation applications. Their exceptional thermal conductivity paired with electrical insulation properties secures their pivotal role in thermal management systems. Among its thermal physical parameters, specific heat capacity significantly influences the thermal performance of these pads. This article delves into the specifics of the specific heat capacity of thermal conductive pads, elucidating its importance and impacting factors in practical applications.

Definition and Significance of Specific Heat Capacity

Specific heat capacity (also known as specific heat) refers to the amount of heat energy required to raise the temperature of one unit mass of a substance by one degree Celsius. It signifies a material's ability to store thermal energy. In thermal management applications, specific heat capacity is a crucial parameter for assessing material thermal properties. For thermal conductive pads, specific heat capacity governs their effectiveness in absorbing and releasing heat during thermal conduction, thereby ensuring stable operation of electronic devices.

Characteristics of Specific Heat Capacity in Thermal Conductive Pads

Thermal conductive pads primarily consist of silicone rubber and thermally conductive fillers. Silicone rubber typically has a specific heat capacity ranging from 1.1 to 1.5 J/(g·°C), whereas different fillers such as aluminum oxide, boron nitride, or carbon nanotubes each possess distinct specific heat capacities. The addition of these fillers enhances thermal conductivity but also alters the specific heat capacity.

Factors Affecting Specific Heat Capacity of Thermal Conductive Pads

1. Material Composition: The ratio of silicone rubber to thermally conductive filler directly impacts specific heat capacity. Generally, higher filler content, which typically has a lower specific heat capacity, reduces the overall specific heat of the silicone sheet.

2. Filler Type: Different fillers exhibit varying specific heat capacities. For instance, aluminum oxide has a lower specific heat compared to boron nitride. Selecting the right filler can thus modulate the specific heat capacity of the silicone sheet.

3. Density and Structure: The density and microstructure of the thermal conductive silicone sheet also influence its specific heat capacity. High-density pads with evenly dispersed fillers improve thermal conductivity and affect the specific heat.

Impact of Specific Heat Capacity on Application Performance

In practical applications, specific heat capacity significantly affects the thermal management efficacy of pads. Materials with high specific heat excel in environments with significant temperature fluctuations, effectively absorbing and releasing heat to maintain device temperature stability. Conversely, low specific heat materials are suited for rapid heat transfer, preventing localized overheating.

Case Studies in Specific Applications

1. Electronic Device Cooling: In high-power electronics like CPUs and GPUs, thermal conductive pads serve as thermal interface materials, where their specific heat capacity is vital for effective heat management and preventing thermal damage.

2. Electric Vehicle Battery Management: EV batteries generate substantial heat during operation, necessitating thermal conductive pads in their thermal management systems with appropriate specific heat capacity to ensure temperature stability under varying conditions.

3. LED Lighting: In LED lighting, where heat generation during operation is a concern, thermal conductive pads are employed in heat dissipation, with their specific heat capacity influencing LED thermal stability and lifespan.

Conclusion

The specific heat capacity of thermal conductive pads is a critical thermal performance indicator, directly impacting their effectiveness in thermal management systems. By comprehending its definition and influence on the material’s properties, engineers can better select and design thermal materials tailored to specific applications, addressing the escalating demand for efficient cooling and safeguarding long-term, stable operation and energy efficiency of electronic devices.

CN >

CN >