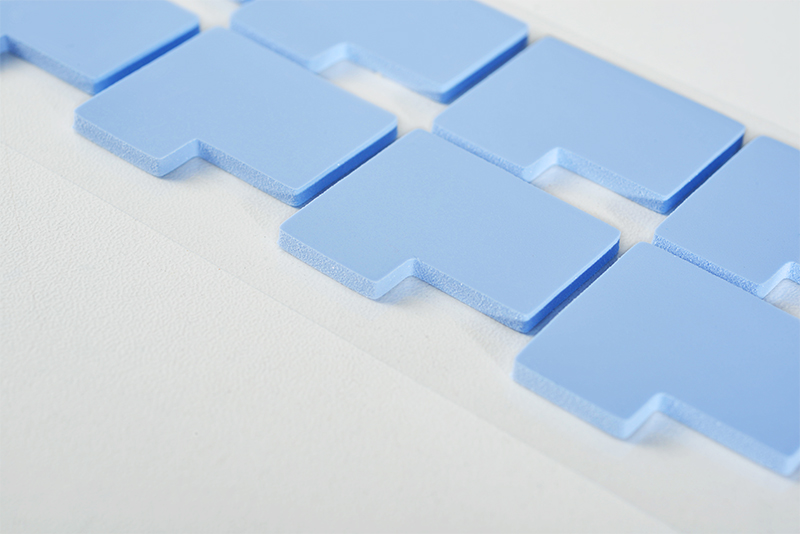

Thermal silicone pads are widely used in electronic devices for thermal management. The effectiveness of their thermal performance directly impacts the stability and lifespan of the equipment. Among the key factors considered when selecting materials, thermal conductivity stands out as a crucial metric for evaluating a material's heat transfer capability. So, is a higher thermal conductivity always better for thermal silicone pads? NFION will explore this question from multiple perspectives to provide scientific guidance for thermal management engineers.

The Core Significance of Thermal Conductivity

Thermal conductivity is a key parameter that measures a material's ability to conduct heat, directly influencing the rate at which heat is transferred from the heat source to the heat sink. In theory, a higher thermal conductivity means faster heat transfer, which is critical for maintaining the efficient operation of devices. However, in practical applications, we must consider the functions that thermal silicone pads need to perform within the thermal management system and their compatibility with other components.

Importance of Thermal Conductivity in Thermal Silicone Pads

Advantages of High Thermal Conductivity:

1. Efficient Heat Dissipation: High thermal conductivity silicone pads can quickly transfer heat from the heat source to the heat sink, helping electronic components maintain lower operating temperatures and thereby enhancing the reliability and lifespan of the equipment.

2. Reduced Thermal Resistance: Lower thermal resistance in the heat path means higher heat transfer efficiency. High thermal conductivity materials can significantly reduce thermal interface resistance, improving the overall efficiency of the cooling system.

3. Superior Thermal Management Performance: In high power density applications, such as high-performance computers, servers, and electric vehicles, high thermal conductivity silicone pads can greatly enhance overall thermal management, preventing local overheating issues.

4. Adaptability to Harsh Environments: Applications in high-temperature environments, such as industrial control equipment and avionics, require high thermal conductivity materials to ensure stable operation.

Advantages of Low Thermal Conductivity:

1. Cost-Effectiveness: Low thermal conductivity silicone pads are usually cheaper, which can effectively reduce material costs for applications with low thermal management requirements.

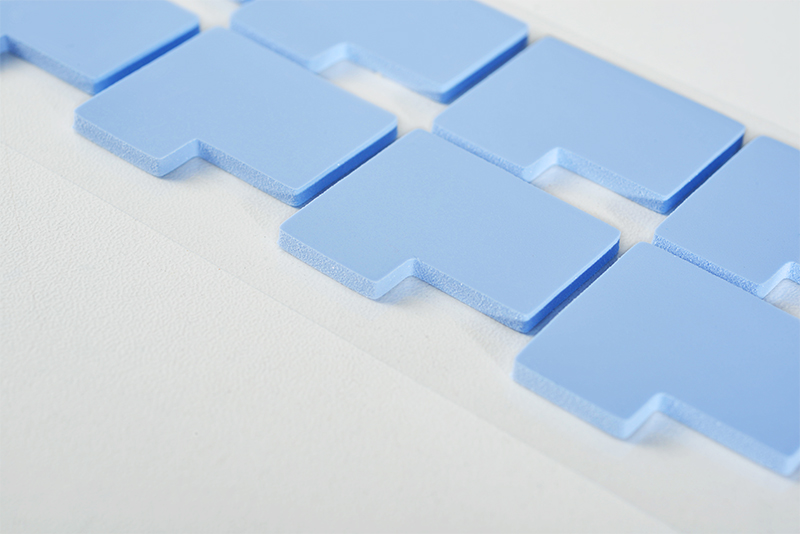

2. Design Flexibility: Lower thermal conductivity silicone pads often have better flexibility and compressibility, facilitating installation in complex or compact spaces. This can improve production efficiency, especially in large-scale manufacturing.

3. Suitable for Low-Power Applications: For low-power, low-heat electronic devices, such as small sensors or low-power chips, low thermal conductivity silicone pads can adequately meet the heat dissipation needs.

Coexisting Challenges

High thermal conductivity materials tend to be more expensive and may compromise on flexibility and compressibility, posing challenges for installation and long-term stability of the pads. Additionally, if other parts of the cooling system (like heat sinks or fans) cannot match the high-efficiency heat transfer rate, the advantages of high thermal conductivity will not be fully realized. Conversely, if the thermal conductivity is too low, heat may not be transferred efficiently, causing the temperature of the heat-generating components to rise and affecting the stable operation of the equipment.

Application Scenario Analysis

High Power Density Equipment:

In high power density devices, such as high-performance computing equipment, 5G communication base stations, and electric vehicle battery management systems, rapid heat conduction and dissipation are crucial. These devices generate significant heat and require high thermal conductivity silicone pads to effectively manage heat and ensure stable operation.

Low Power Electronic Devices:

For low-power electronic devices, such as small sensors and low-power chips in consumer electronics, the thermal management requirements are relatively low. In these cases, low thermal conductivity silicone pads can meet the heat dissipation needs while also reducing costs.

Industrial Control Equipment:

Industrial control equipment often operates in high-temperature and harsh environments, requiring reliable thermal management. Depending on the specific heat generation and operating environment, the appropriate thermal conductivity of silicone pads should be chosen to balance performance and cost.

Comprehensive Strategy for Selecting Thermal Conductivity

When selecting thermal silicone pads for practical applications, the following factors should be considered:

- Application Environment: Determine the minimum required thermal conductivity based on the operating temperature range and power density of the equipment.

- System Compatibility: Assess the capability of the entire thermal management system to ensure the thermal conductivity of the silicone pads matches other components.

- Cost-Effectiveness: Balance material costs, production costs, and long-term maintenance costs while meeting performance requirements.

Conclusion

The choice of thermal conductivity for thermal silicone pads should be balanced based on specific application scenarios and thermal management needs. High thermal conductivity materials are suitable for high power density and high thermal demand devices, while low thermal conductivity materials are ideal for low power and cost-sensitive applications. A rational selection of thermal conductivity can optimize thermal management performance and strike the best balance between performance and cost.

In summary, the thermal conductivity of thermal silicone pads is neither inherently better when higher nor worse when lower; it should be selected according to the specific application needs. Understanding and leveraging the role of thermal conductivity can help us make better material choices and thermal management designs, ensuring electronic devices operate stably and efficiently in various environments.

CN >

CN >