Thermally Conductive Silicone Pads Enhance NEV Heat Dissipation Efficiency

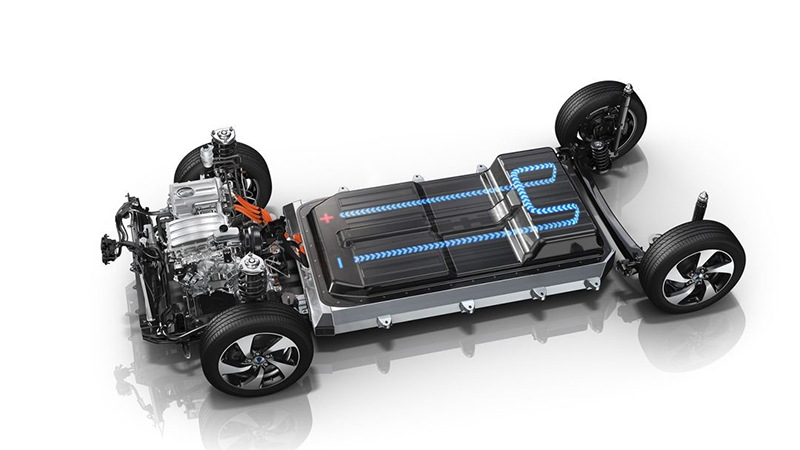

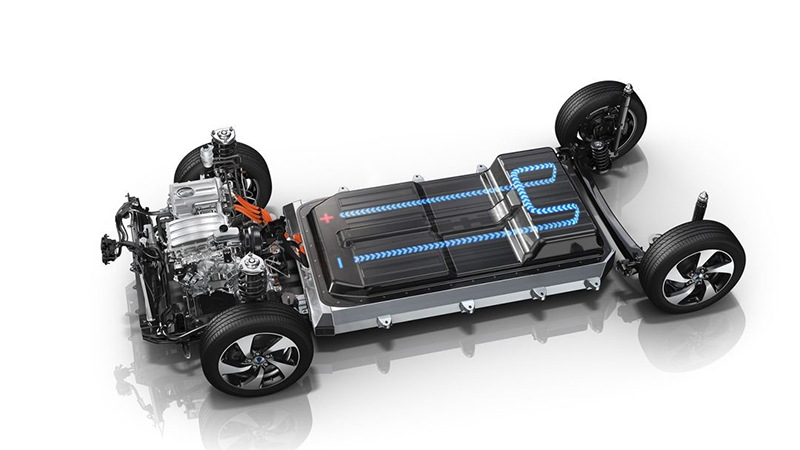

Amidst the increasingly prominent global energy crisis and environmental pollution issues, new energy vehicles (NEVs), as a green and environmentally friendly mode of transportation, are gradually receiving widespread attention and support from all sectors of society. With continuous technological advancements and deeper application, NEVs have made significant progress in power performance, driving range, and intelligence levels. However, the heat dissipation issue in NEV electronic control systems has become a major bottleneck affecting their performance and reliability. Thermally conductive silicone pads, as a new type of heat dissipation material, provide an effective solution to this problem due to their excellent thermal conductivity and flexible application methods.

The Heat Dissipation Challenge in NEV Electronic Control Systems

Causes of Heat Dissipation Issues

The heat dissipation challenges in NEV electronic control systems mainly stem from the following aspects:

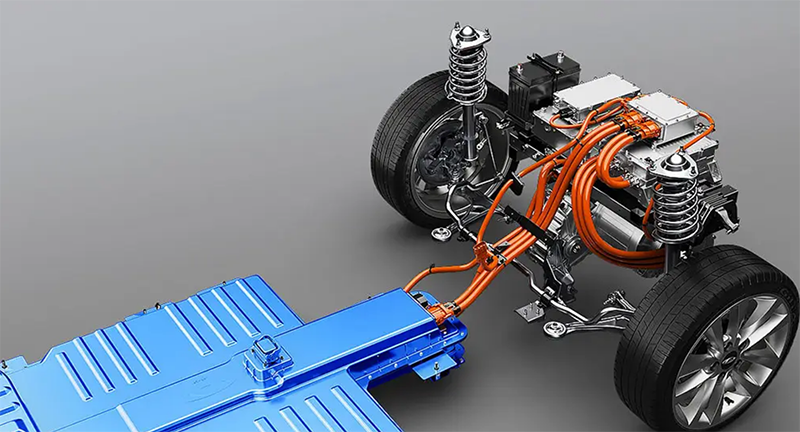

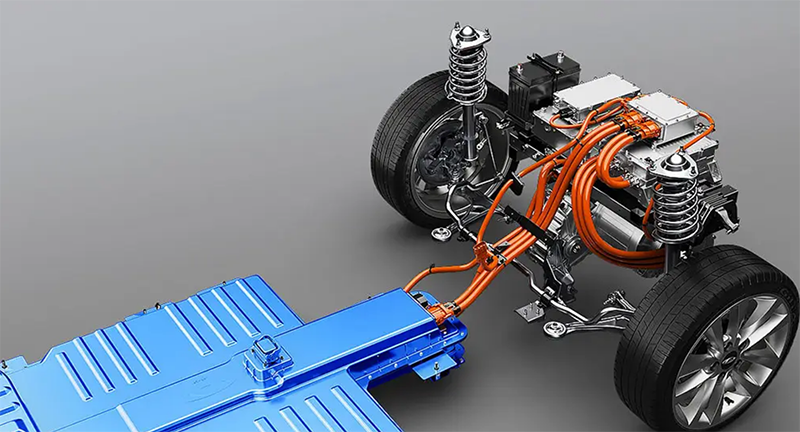

1. High Power Density: Power electronic devices in NEV electronic control systems, such as motor controllers, inverters, and battery management systems, have high power density, generating concentrated heat that can easily lead to localized overheating.

2. Compact Packaging: To reduce size and weight, the design of electronic control systems tends towards high integration and compact packaging, which increases the difficulty of heat conduction and dissipation.

3. Wide Range of Ambient Temperature Changes: During driving, NEVs experience significant changes in external ambient temperature, imposing higher demands on the heat dissipation design of the electronic control systems.

Impact of Heat Dissipation Issues

Poor heat dissipation in electronic control systems can lead to a series of problems, including:

1. Performance Degradation: Excessive temperatures can affect the performance of power electronic devices, leading to reduced system efficiency.

2. Shortened Lifespan: Prolonged operation at high temperatures accelerates the aging of electronic components, shortening their service life.

3. Safety Hazards: Severe overheating may cause electronic control system failures and even lead to safety incidents such as fires.

Basic Characteristics of Thermally Conductive Silicone Pads

1. Thermal Conductivity: Thermally conductive silicone pads have good thermal conductivity, effectively transferring heat from the heat source to the heat sink or other heat dissipation components. Their thermal conductivity typically ranges from 1.0 to 10.0 W/mK, achieved by filling the silicone matrix with highly thermally conductive ceramic particles such as alumina and boron nitride.

2. Insulating Properties: In addition to excellent thermal conductivity, thermally conductive silicone pads possess outstanding electrical insulation properties, preventing electrical short circuits while conducting heat, thereby ensuring the safety of the electronic control system. This makes them particularly suitable for thermal management of power electronic devices.

3. Flexibility and Compressibility: Thermally conductive silicone pads are highly flexible and compressible, allowing them to closely conform to the heat source and heat sink under pressure, eliminating air gaps at the interface, reducing thermal resistance, and enhancing heat dissipation efficiency. Their flexibility also makes installation and maintenance more convenient, accommodating complex system structures.

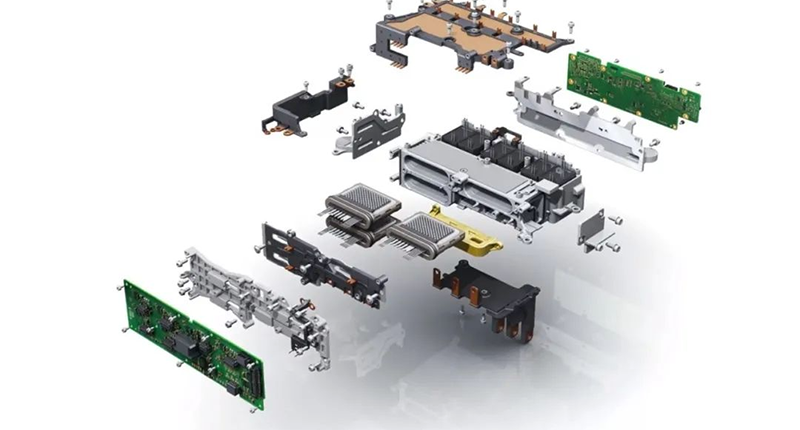

Applications of Thermally Conductive Silicone Pads in NEV Electronic Control Systems

Thermally conductive silicone pads are applied in the heat dissipation of NEV electronic control systems in several key areas:

1. Battery Management System (BMS) Heat Dissipation: The BMS is a core component of the NEV electronic control system, directly affecting the safety and stability of the battery pack. Attaching thermally conductive silicone pads to the BMS surface can quickly transfer generated heat to the heat sink, enhancing heat dissipation efficiency and ensuring normal BMS operation.

2. Motor Controller (MCU) Heat Dissipation: The MCU is a crucial part of the NEV motor control system, with its heat dissipation performance directly impacting motor efficiency and lifespan. Thermally conductive silicone pads can closely adhere to the MCU surface, filling gaps and effectively reducing thermal resistance, thereby improving heat dissipation efficiency.

3. Electronic Control Unit (ECU) Heat Dissipation: The ECU is the core component of the NEV body control system, responsible for controlling various vehicle functions and parameters. By attaching thermally conductive silicone pads to the ECU surface, heat can be rapidly conducted to the heat sink, ensuring the ECU's normal operation.

Advantages and Challenges of Thermally Conductive Silicone Pads

Advantages:

1. High Thermal Efficiency: Thermally conductive silicone pads achieve efficient heat transfer, significantly reducing the operating temperature of the system, and improving its reliability and performance.

2. Electrical Insulation: Their excellent electrical insulation properties ensure the safety of the electronic control system by preventing electrical short circuits.

3. Ease of Installation: The good flexibility and strong compressibility of thermally conductive silicone pads make installation and maintenance convenient, fitting heat sources of various shapes and structures.

4. Environmental Adaptability: Thermally conductive silicone pads are high-temperature resistant and anti-aging, capable of stable long-term operation in harsh environments.

Challenges:

1. Cost Considerations: High-quality thermally conductive silicone pads are relatively expensive, necessitating economic considerations for large-scale applications.

2. Reliability Testing: In practical applications, thermally conductive silicone pads require rigorous reliability testing to ensure stable performance under various working conditions.

3. Optimized Design: Optimized designs are needed for different application scenarios to achieve the best heat dissipation results.

Future Development Directions

1. Material Innovation: With continuous advancements in material science, the composition and production process of thermally conductive silicone pads are also being optimized. The application of new thermal fillers and modified silicone matrices is expected to further enhance thermal and mechanical properties, reduce costs, and expand application scope.

2. Multifunctional Integration: Future thermally conductive silicone pads may integrate additional functions such as electromagnetic interference resistance and environmental monitoring, improving the overall performance of the system.

3. Application Expansion: As NEV technology continues to develop, the application scenarios for thermally conductive silicone pads will expand. Besides electronic control systems, they can play significant roles in onboard chargers, battery packs, and other electronic devices, further enhancing the overall performance and reliability of NEVs.

Conclusion

With excellent thermal conductivity, good electrical insulation, flexibility, and compressibility, thermally conductive silicone pads offer an effective solution to the heat dissipation challenges in NEV electronic control systems. Despite facing challenges in cost, reliability testing, and optimized design, continuous technological advancements and deeper applications point to a promising future for thermally conductive silicone pads in the NEV industry. In the future, through material innovation and multifunctional development, thermally conductive silicone pads will further enhance their overall performance, providing robust support for the sustainable development of NEVs.

As NEVs become a crucial direction for future transportation development, the performance and reliability of their electronic control systems are vital to the vehicle's safety and efficiency. The successful application of thermally conductive silicone pads in this field not only provides an effective solution to the heat dissipation problem but also significantly contributes to the overall technological advancement of NEVs. With continuous technological evolution and widespread application, thermally conductive silicone pads are poised to play an increasingly important role in the NEV industry.

CN >

CN >