With the continuous development of modern architecture and the acceleration of urbanization, elevators have become an indispensable vertical transportation means in people's daily life and work. The safety, reliability, and efficiency of elevator operation are crucial for ensuring the transport of personnel and goods. Within the elevator system, the drive module is a core component responsible for providing the power that enables smooth elevator operation. However, during operation, this module generates a significant amount of heat. If effective thermal management is not implemented, it can lead to performance degradation, failures, or even damage to the module, thus affecting the normal functioning of the elevator. Therefore, exploring the necessity of thermal management for elevator drive modules holds significant practical importance.

Working Principles and Heat Generation Causes of Elevator Drive Modules

(1) Working Principles

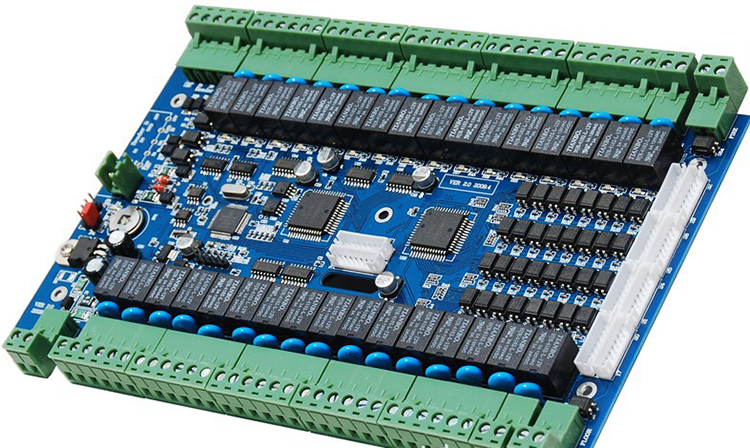

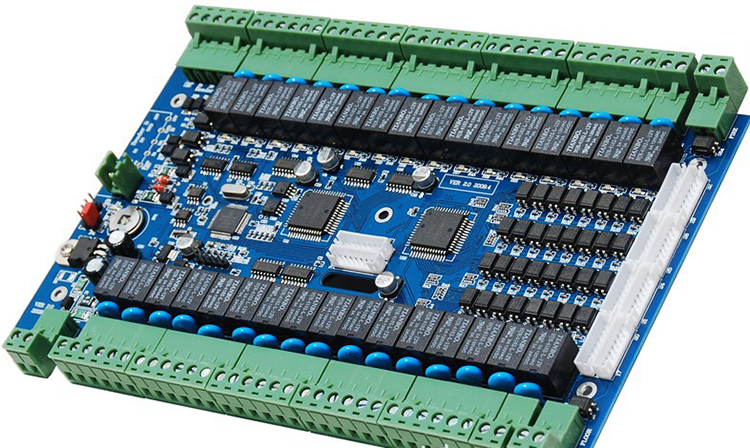

Elevator drive modules typically consist of electric motors, variable frequency drives (VFDs), control systems, etc. The electric motor, as the core component, converts electrical energy into mechanical energy to power the elevator's movement. VFDs regulate the motor's speed and torque, enabling smooth starting, acceleration, deceleration, and stopping of the elevator. The control system oversees the entire drive module's operation, including motor start/stop, speed and torque adjustments, fault diagnosis, among others.

(2) Causes of Heat Generation

The primary reasons for heat generation during the operation of elevator drive modules are:

Motor Losses: Electric motors generate copper losses, iron losses, and mechanical losses during operation, all of which convert into heat.

VFD Losses: Variable frequency drives also incur losses during operation, such as switching losses and conduction losses, which likewise transform into heat.

Control System Losses: Electronic components within the control system generate heat during their operation.

Importance of Thermal Management for Elevator Drive Modules

(1) Enhancing Module Performance

Temperature significantly affects the performance of electronic components. Increased temperature leads to increased resistance, reducing current flow and thereby impacting module performance. Effective thermal management can lower temperatures, enhance component performance, and ensure the normal operation of the drive module.

(2) Extending Module Lifespan

High temperatures accelerate the aging and failure of electronic components, shortening the module's lifespan. By effectively managing temperature, the aging process slows down, prolonging the module's life.

(3) Improving System Reliability

Excessive heat in the drive module can cause malfunctions or damage, affecting elevator operations. Efficient thermal management reduces temperatures, enhancing system reliability and ensuring safe elevator operations.

Thermal Management Methods for Elevator Drive Modules

(1) Heat Dissipation Design

Heat sinks are commonly installed in drive modules to increase the surface area for heat dissipation, improving efficiency.

Fans facilitate airflow to remove heat. Selection should consider factors like airflow volume, pressure, and noise.

Heat pipes are high-efficiency heat transfer components that rapidly move heat from the source to heat sinks.

(2) Cooling Design

Air cooling relies on airflow to dissipate heat. Design considerations include air volume, velocity, and pressure.

Liquid cooling uses circulating coolant to remove heat, offering high efficiency and uniform temperature distribution but at a higher cost.

(3) Thermal Interface Materials

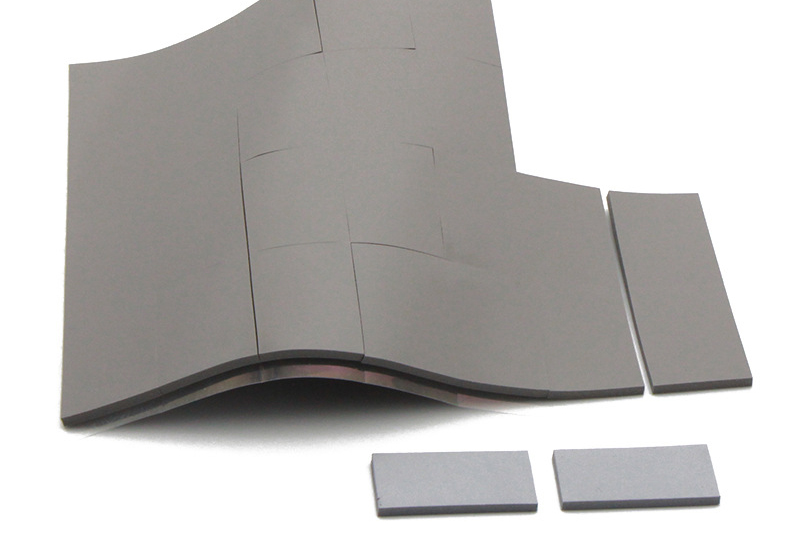

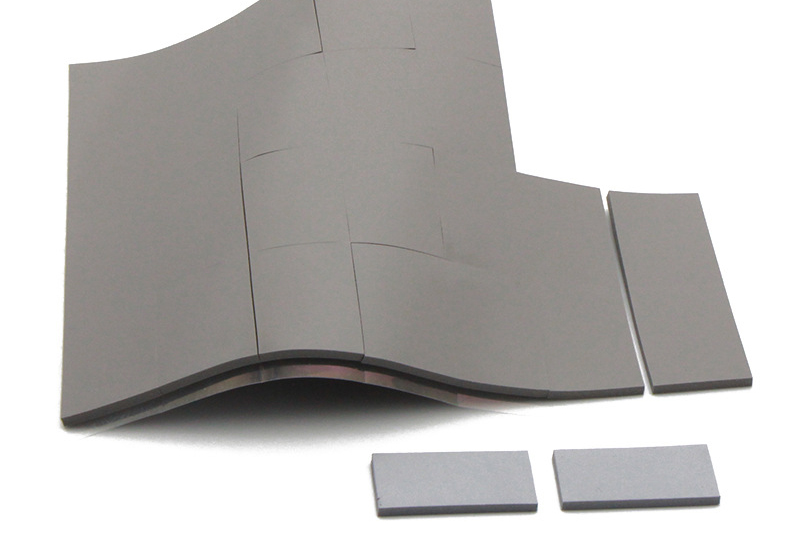

These materials fill gaps between heat sources and heat sinks, reducing thermal resistance and improving heat dissipation. Common examples include thermal silicone, thermal grease, and thermal pads.

(4) Temperature Monitoring and Control

To ensure safe temperatures, modules require monitoring through temperature sensors and control via fan speed adjustment or coolant flow regulation.

Challenges and Solutions in Elevator Drive Module Thermal Management

(1) Space Constraints

Limited space in elevator machine rooms necessitates consideration of spatial limitations when designing thermal management systems, selecting appropriate cooling and dissipation methods.

(2) Noise Issues

Heat dissipation devices like fans can be noisy. Low-noise options or noise reduction measures must be considered.

(3) Cost Considerations

Thermal management systems can be costly, potentially increasing overall elevator costs. Designs must balance cost and performance to select the right solution.

(4) Reliability Concerns

The thermal management system itself must be highly reliable to ensure elevator safety. High-quality, rigorously tested components are essential.

Conclusion

In conclusion, thermal management of elevator drive modules is imperative. It enhances performance, prolongs lifespan, and ensures system reliability for safe elevator operation. Design considerations encompass heat dissipation, cooling, interface materials, and temperature controls, addressing challenges like space constraints, noise, cost, and reliability. As elevator technology progresses, demands for advanced thermal management will escalate. Continuous innovation in thermal management techniques is vital to meet industry needs. Recognizing that thermal management spans design, manufacturing, installation, and maintenance, collaboration among elevator manufacturers, installers, and maintenance providers is crucial to achieve effective thermal management, ensuring safe, reliable, and efficient elevator operations.

CN >

CN >