In the modern kitchen, induction cookers have become a commonly used cooking tool in many households due to their high efficiency, convenience, and safety. However, as induction cookers are used for a long time, the heat dissipation problem gradually emerges, and thermal grease plays an important role in solving this key problem.

However, relying solely on heat sinks and fans is not enough to completely solve the heat dissipation problem, because there is an air gap between the heating element and the heat sink, and the thermal conductivity of air is poor, which will hinder the effective transfer of heat.

Specifically, thermal grease has the following important functions:

1. Improved thermal conductivity: The thermal conductivity of thermal grease is usually much higher than that of air, which can greatly reduce heat loss during the transfer process and allow heat to be transferred from the heating element to the heat sink more quickly.

2. Reduced thermal resistance: Thermal resistance is an indicator of the difficulty of heat transfer. The use of thermal grease can reduce the thermal resistance between the heating element and the heat sink, thereby further improving the heat dissipation effect.

3. Filled gaps: As mentioned earlier, there are inevitable gaps between the heating element and the heat sink. Thermal grease can fill these gaps well to ensure that heat is transferred evenly.

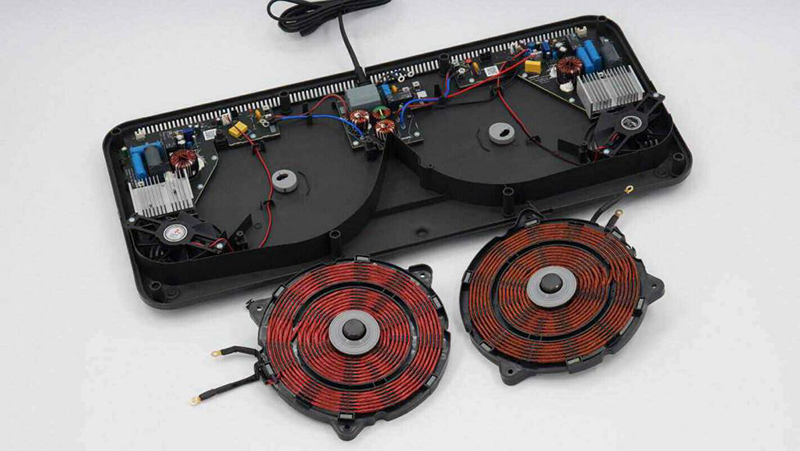

The heat dissipation design of induction cookers usually involves multiple aspects, including heat dissipation treatment of key heating components such as coil pans and IGBT (Insulated Gate Bipolar Transistor). The application of thermal grease mainly focuses on the following areas:

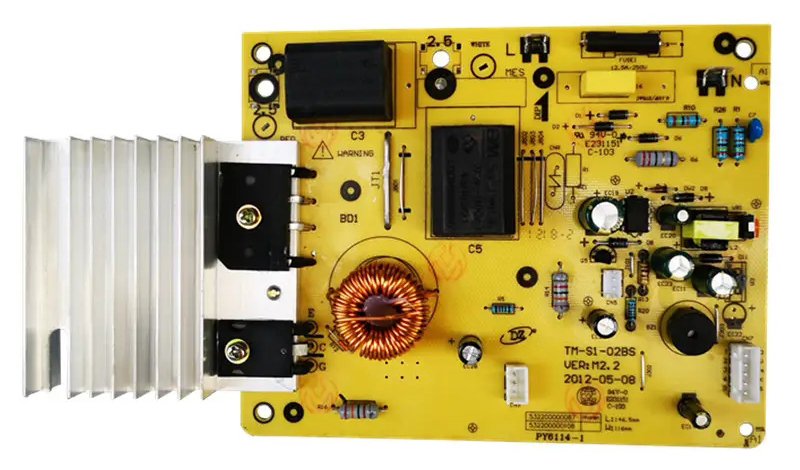

1. IGBT module heat dissipation: As the core device for power conversion in induction cookers, the IGBT's heat dissipation is crucial. By applying thermal grease between the IGBT and the heat sink, the temperature rise during operation can be effectively reduced, improving the overall system stability and lifespan.

2. Heat dissipation at the bottom of the coil pan: Although the coil pan is in direct contact with air, the part where it contacts the circuit board at the bottom is also a heat accumulation area. Appropriate thermal grease can improve the heat conduction efficiency of this part and accelerate heat dissipation.

3. Heat dissipation of the control circuit board: The control circuit board of the induction cooker also requires good heat dissipation measures. Thermal grease can be applied to the contact surface between the circuit board and the shell or a dedicated heat sink to ensure that electronic components operate within an appropriate temperature range.

There are various types and brands of thermal grease on the market, and choosing the right one is crucial for the heat dissipation effect of induction cookers. The following are some factors to consider when selecting thermal grease:

1. Thermal conductivity: Thermal conductivity is a key indicator of the thermal conductivity of thermal grease. Generally, the higher the thermal conductivity, the better the heat dissipation effect. However, it should be noted that thermal grease with too high a thermal conductivity may be more expensive, and in some cases, it may affect its other properties, such as fluidity and viscosity.

2. Fluidity: The fluidity of thermal grease will affect its filling effect between the heating element and the heat sink. Thermal grease that is too fluid may flow out during use, while thermal grease that is too viscous may not be able to fill the gap evenly.

3. Viscosity: Appropriate viscosity of thermal grease can better adhere to the heating element and the heat sink, avoiding detachment during use. However, thermal grease with too high viscosity may cause difficulties in installation and removal.

To ensure the heat dissipation effect of induction cookers, it is recommended to choose NFION thermal grease with a thermal conductivity of 3W/m.k. The advantages of this thermal grease are as follows:

1. Excellent thermal conductivity: The thermal conductivity of 3W/m.k means that this thermal grease has excellent thermal conductivity, which can effectively transfer heat from the heating element to the heat sink, thereby improving the heat dissipation efficiency.

2. Good fluidity and viscosity: This thermal grease has good fluidity and viscosity, which can evenly fill the gap between the heating element and the heat sink, ensuring even heat transfer and high efficiency.

3. Outstanding durability: NFION thermal grease has undergone strict testing and verification and has excellent durability and stability. It can maintain its performance over a long period of time without deterioration or drying out.

4. Wide application range: This thermal grease is suitable for various types and powers of induction cookers, including household induction cookers and commercial induction cookers. It can exhibit excellent heat dissipation effects in both high-temperature and normal environments.

Proper use of thermal grease is also an important part in ensuring the heat dissipation effect of induction cookers. The following are the general steps for using thermal grease:

1. Clean the surface: Before applying the thermal grease, clean the surfaces of the heating element and the heat sink to remove dust, oil, and other impurities to ensure good adhesion of the thermal grease.

2. Apply the thermal grease: Squeeze an appropriate amount of thermal grease onto the surface of the heating element or the heat sink, and then use a scraper or other tool to spread it evenly to ensure that the entire contact area is covered.

3. Install the heat sink: Place the heating element coated with thermal grease in close contact with the heat sink, and fix them together using screws or other fasteners.

When replacing the thermal grease, follow the above application method to reapply and reinstall. During the disassembly and installation process, be careful not to damage the electronic components.

In addition to thermal grease, there are other factors that can affect the heat dissipation effect of induction cookers:

1. Design and material of the heat sink: The surface area, shape, and material of the heat sink all affect its heat dissipation performance. A high-quality heat sink should have a large surface area, a reasonable shape, and good thermal conductivity.

2. Performance of the fan: The speed, air volume, and noise of the fan are also important factors affecting the heat dissipation effect. A high-performance fan can effectively improve the heat dissipation efficiency while maintaining a low noise level.

With the continuous progress of technology, thermal grease is also constantly evolving and innovating. In the future, we can expect the following development trends:

1. Higher thermal conductivity: Developing thermal grease with higher thermal conductivity to further improve the heat dissipation effect of induction cookers.

2. Better durability: Developing thermal grease with better durability to extend its service life and reduce the frequency of replacement.

CN >

CN >