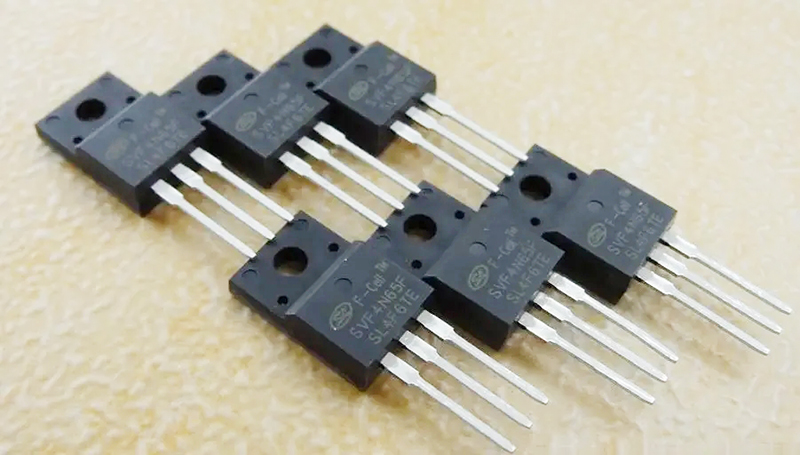

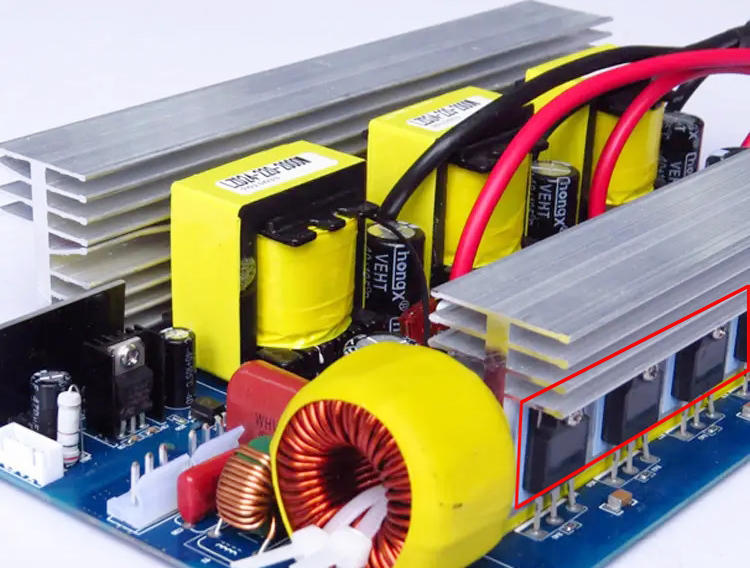

The Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET), a crucial component in modern electronic devices, is an essential element that controls the output current by regulating the input voltage or current, thereby realizing functions such as switching, amplification, and voltage stabilization in electronic devices. However, MOSFETs generate substantial heat during operation; failure to dissipate this heat promptly can lead to reduced device performance or even damage. Therefore, an effective cooling solution is vital for the stable functioning of MOSFETs.

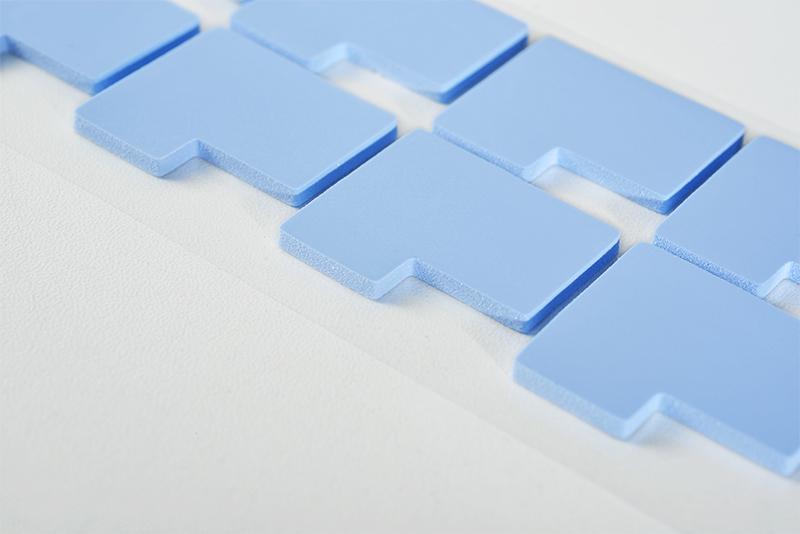

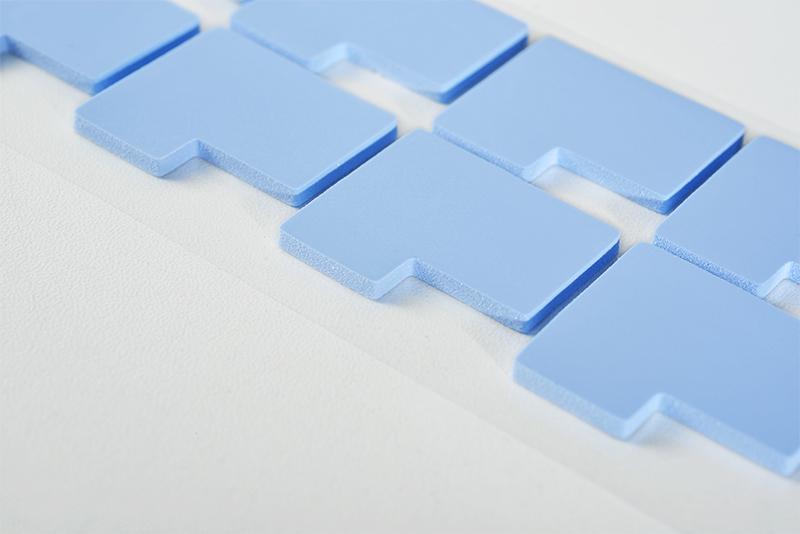

Thermal conductive silicone pads, as an efficient thermal conduction interfece material, have increasingly gained attention in recent years for their application in MOSFET cooling solutions. These pads feature excellent thermal conductivity, electrical insulation, aging resistance, and corrosion resistance, efficiently transferring the heat generated by MOSFETs away and ensuring normal device operation.

1. Heat Dissipation Function

As a power semiconductor device, MOSFETs are commonly used as power switching elements in power supplies, motor drives, inverters, and other power electronic equipment. Under high-frequency and high-current operating conditions, MOSFETs incur significant power losses, primarily converted into heat. If this heat is not dissipated effectively and promptly, it can cause the internal junction temperature of the MOSFET to rise, impacting its performance (e.g., increased on-resistance, decreased switching speed) and potentially triggering overheat protection mechanisms, shortening the device's lifespan, or even causing permanent damage.

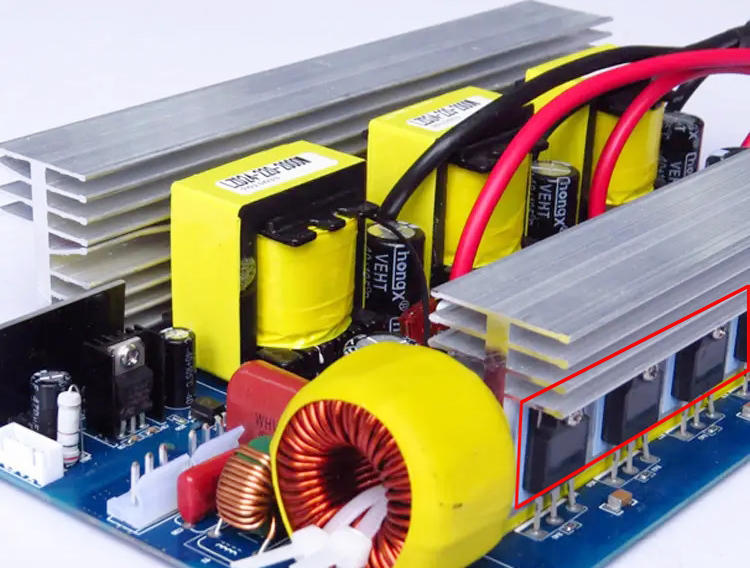

A thermal conductive silicone pad, being a high-performance elastic material with superior thermal conductivity, fills the gap between the MOSFET and the heat sink (such as a heatsink or heat spreader), effectively transmitting and spreading the heat generated by the MOSFET, reducing its junction temperature, and ensuring that the device operates within a safe temperature range, thereby enhancing overall system reliability and stability.

2. Insulation Role

MOSFETs typically require electrical isolation from heat sinks to prevent short circuits or leakage. Thermal conductive silicone pads not only exhibit excellent thermal conductivity but also offer outstanding insulation properties, allowing for heat transfer while preventing direct contact between different potentials, thus providing necessary electrical isolation. This dual functionality makes thermal conductive silicone pads an ideal thermal management solution, particularly suitable for high-voltage and high-power applications.

3. Adaptability and Convenience

Thermal conductive silicone pads possess several characteristics that contribute to their good adaptability and convenience when applied to MOSFETs:

Flexibility and Compressibility: The silicone pads can easily accommodate minor surface irregularities between the MOSFET and the heat sink, filling molecular gaps through deformation under pressure to create an effective thermal contact surface, lowering interface thermal resistance. Even under vibration or varying coefficients of thermal expansion, they maintain a strong bond, avoiding increased thermal resistance due to poor contact.

Self-adhesion or Weak Adhesion: Many thermal conductive silicone pads come with inherent adhesion, allowing them to be firmly fixed between the MOSFET and the heat sink without requiring additional adhesives, simplifying assembly and making removal or replacement easy if needed.

Anti-aging and Reliability: High-quality thermal conductive silicone pads usually have excellent high-temperature, low-temperature, and anti-aging properties, maintaining stable thermal and insulation performance over time, regardless of environmental factors (such as humidity and temperature changes).

Environmental Friendliness and Certification: Many thermal conductive silicone pad products meet environmental and safety standards like RoHS and UL, making them suitable for various applications with strict environmental and safety requirements.

4. Customization Options

For specific MOSFET application needs, thermal conductive silicone pads can be customized with different thicknesses, hardness, thermal conductivity, voltage withstand levels, and color parameters, catering to diverse power ratings, cooling demands, space constraints, and aesthetic coordination requirements.

In summary, thermal conductive silicone pads play a critical role in thermal management for MOSFET applications. By providing efficient heat dissipation, insulation protection, and exhibiting good adaptability and convenience, they ensure that MOSFETs operate stably, efficiently, and safely under complex working conditions.

CN >

CN >