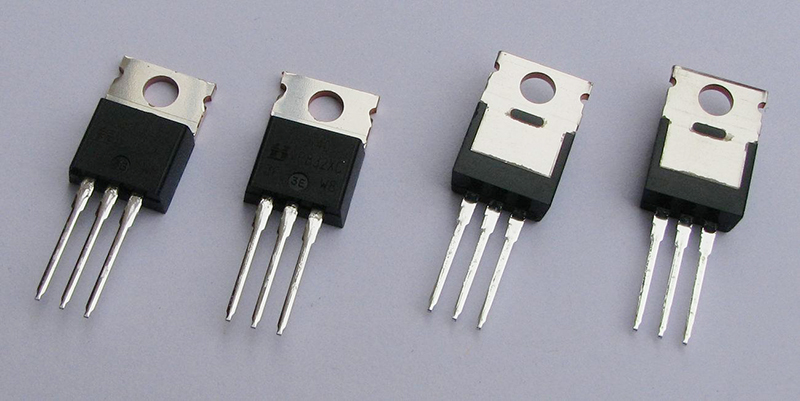

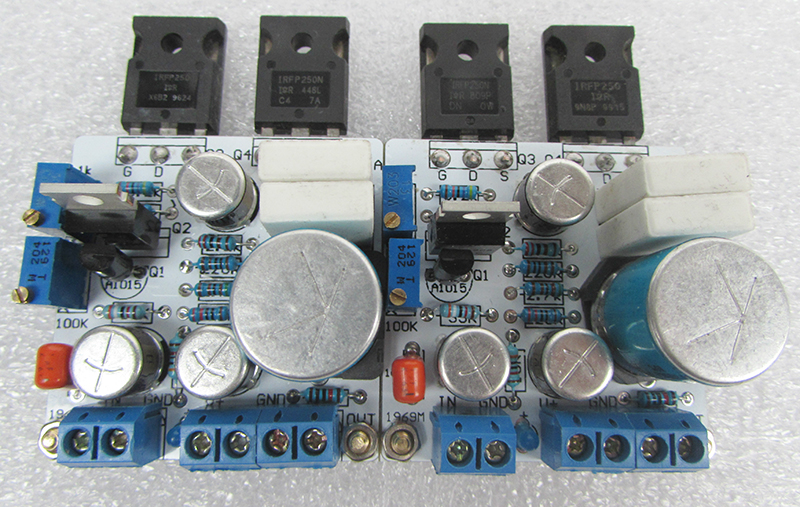

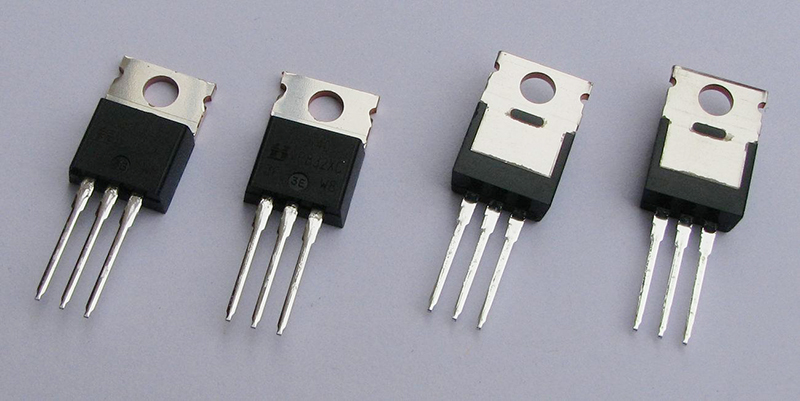

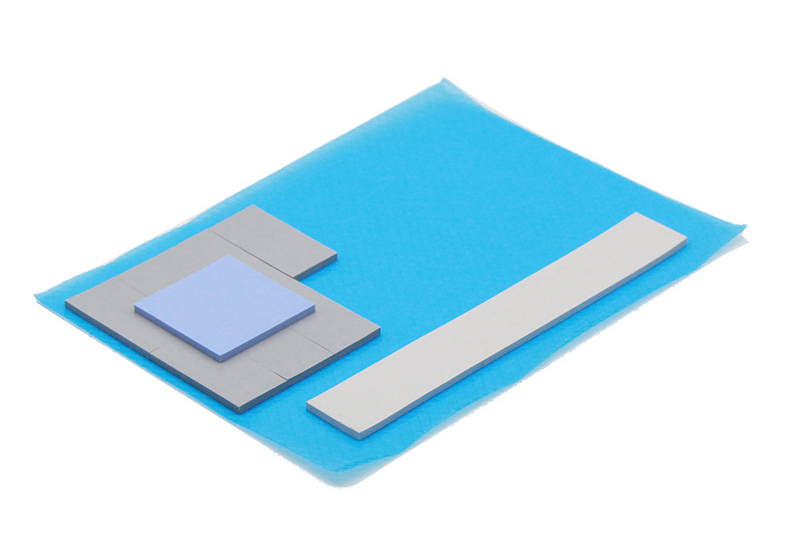

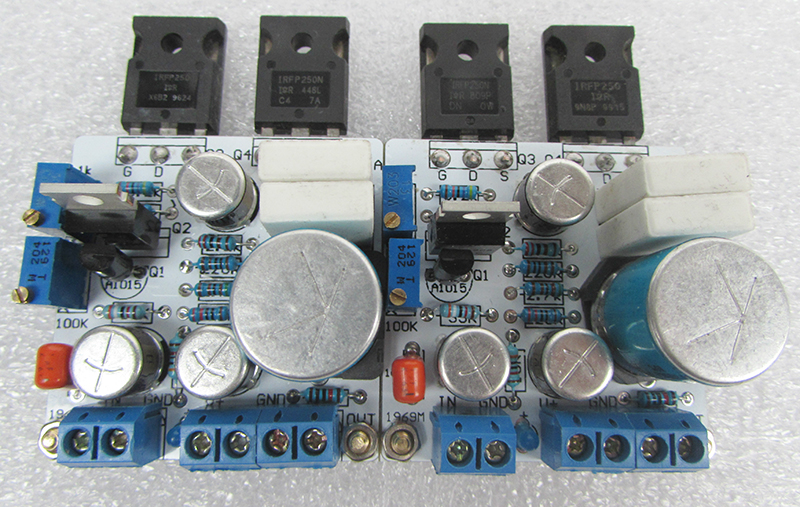

In the application of MOSFETs, thermally conductive silicone pads have undeniably demonstrated their outstanding performance. MOSFETs, as electronic components with relatively high heat generation, play a critical role in ensuring the safety and stability of the entire circuit board. Their heat dissipation efficiency is particularly crucial, especially for those outside the power main chip, where heat dissipation issues cannot be overlooked. The thermally conductive silicone pad acts like a silent guardian, providing stable and efficient cooling support to the MOSFET.

Similarly, thermal grease heat sink paste also deserves praise for its high thermal conductivity performance, which safeguards the stable operation of electronic devices. It functions akin to a nimble artisan, swiftly transferring heat to ensure that the temperature of the equipment remains within a safe range.

Thermal grease heat sink paste plays a vital role in the application of MOSFETs. A Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) is one of the widely used electronic components in modern electronic devices. However, due to the significant amount of heat generated during its operation, if this heat is not dissipated promptly and effectively, it can lead to decreased performance or even damage to the MOSFET. Hence, the application of thermal grease heat sink paste becomes highly important.

Thermal grease heat sink paste is a high-performance thermal management material with excellent thermal conductivity and electrical insulation properties. It creates an effective thermal conduction pathway between the MOSFET and the heat sink. When the MOSFET operates, the generated heat is rapidly transferred through the thermal grease heat sink paste to the heat sink, then dissipated into the surrounding environment, thus achieving effective cooling of the MOSFET.

Here, Nfion Thermal Conductive Materials elaborates on the role and usage of thermal grease heat sink paste in the application of MOSFET:

Role:

1. Filling Gaps and Improving Heat Conduction:

During operation, MOSFETs generate heat, especially in high-power applications, where heat accumulation can be substantial. Even though MOSFETs are typically mounted onto heat sinks for improved cooling, there are often microscopic air gaps between the relatively smooth surface of the MOSFET and the heat sink. These air gaps, being poor conductors of heat, significantly impede heat transfer.

Thermal grease heat sink paste, acting as a high-performance Thermal Interface Material (TIM), fills these minute gaps, eliminates the air layer, and significantly enhances the efficiency of heat transfer from the MOSFET to the heat sink.

2. Enhancing Cooling Performance:

Thermal grease heat sink paste has a low thermal resistance. When applied between the MOSFET and the heat sink, it quickly transfers the heat produced by the MOSFET to the heat sink, which then disperses the heat into the surroundings through its enlarged surface area. This helps lower the operating temperature of the MOSFET, preventing performance degradation, shortened lifespan, or damage caused by overheating.

3. Electrical Insulation and Protection:

Thermal grease heat sink paste not only possesses good thermal conductivity but also excellent electrical insulation properties, preventing accidental current flow through the heat sink that could cause short circuits or other electrical issues. Moreover, its moisture-proof, dust-proof, and corrosion-resistant qualities help protect the MOSFET and surrounding circuits from environmental factors, enhancing the stability and reliability of the device.

4. Adaptability to Temperature Changes and Mechanical Stress:

Thermal grease heat sink paste has a wide operating temperature range (e.g., -40°C to 200°C) and low oil bleeding, allowing it to maintain stable performance over a broad temperature variation without curing, hardening, or flowing. Additionally, its flexible nature absorbs and alleviates mechanical stress caused by differences in thermal expansion coefficients, protecting the interface between the MOSFET and the heat sink from mechanical damage.

Usage Methods:

1. Preparation and Cleaning:

Before use, ensure the surface of the MOSFET and the base of the heat sink are clean, free of impurities, rust, oils, or residual old thermal grease heat sink paste. Clean them using alcohol swabs or specialized cleaning agents, and allow them to dry completely before proceeding.

2. Application:

The amount of thermal grease heat sink paste applied is not "the more, the better," but rather should follow the principle of being "thin and uniform." Typically, squeeze out a small amount of grease and gently spread it evenly across the top of the MOSFET (especially the active region) to form a thin, continuous film. An excessively thick layer of grease can increase thermal resistance and negatively affect cooling efficiency.

3. Assembly and Press-Fit:

Carefully align and press-fit the MOSFET with thermal grease heat sink paste onto the heat sink. For systems with threaded fasteners or clamps, tighten according to the specified torque or pressure to ensure full contact between the MOSFET and the heat sink while avoiding excessive force that may damage the components.

4. Inspection and Maintenance:

After installation, check the application of the thermal grease heat sink paste to ensure no omissions or spills. During the device's operational cycle, periodically inspect the integrity of the cooling system. If necessary, reapply the thermal grease heat sink paste to maintain its optimal thermal management performance.

In summary, thermal grease heat sink paste plays a pivotal role in improving the heat dissipation efficiency of MOSFETs by filling gaps, enhancing heat transfer, providing electrical insulation, and adapting to temperature changes and mechanical stress. Correct selection, application, and maintenance of thermal grease heat sink paste are key steps in ensuring the efficient operation of the MOSFET cooling system, thereby guaranteeing its stability and longevity under high-power working conditions.

CN >

CN >