Although thermal silicone pads and thermal grease are common thermal conductivity interface materials, they have differences in physical forms, use methods, performance characteristics, and application scenarios. Although it can be replaced in some cases, whether it can replace it depends on specific heat dissipation requirements, assembly conditions, and equipment design requirements.

The following are some considerations of whether the thermal conduction silicone pad can replace the silicon grease:

1. Physical form and convenience:

thermal silicone grease: presented paste, easy to apply, can fill a small gap, suitable for occasions that need to be finely applied, such as CPU and GPUs such as semiconductor chips and heat sinks. It is difficult to control the thickness and may need to clean the overflow or residue.

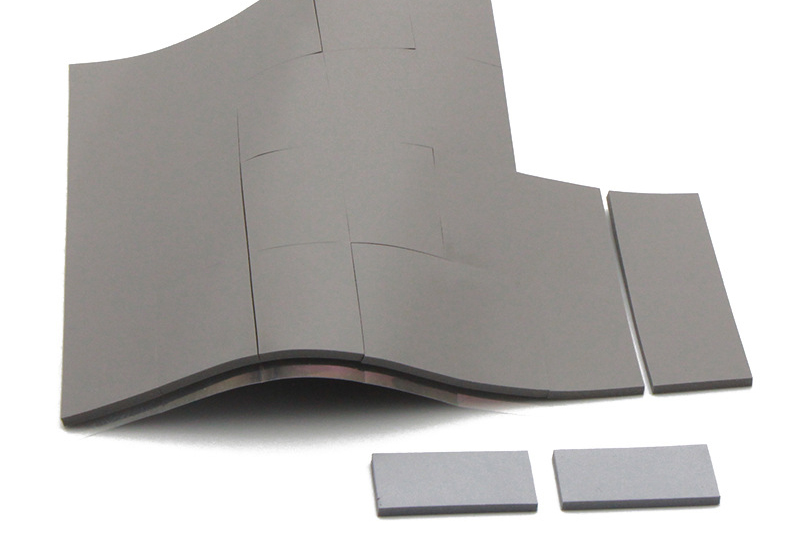

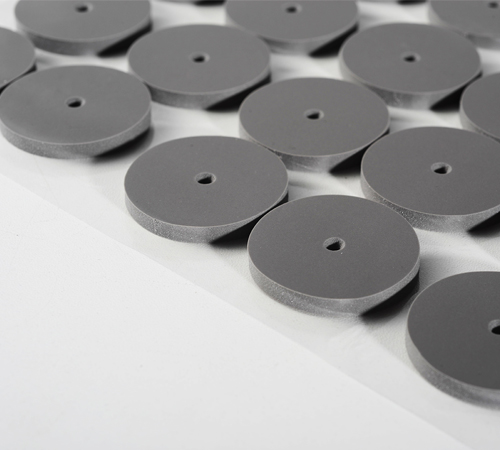

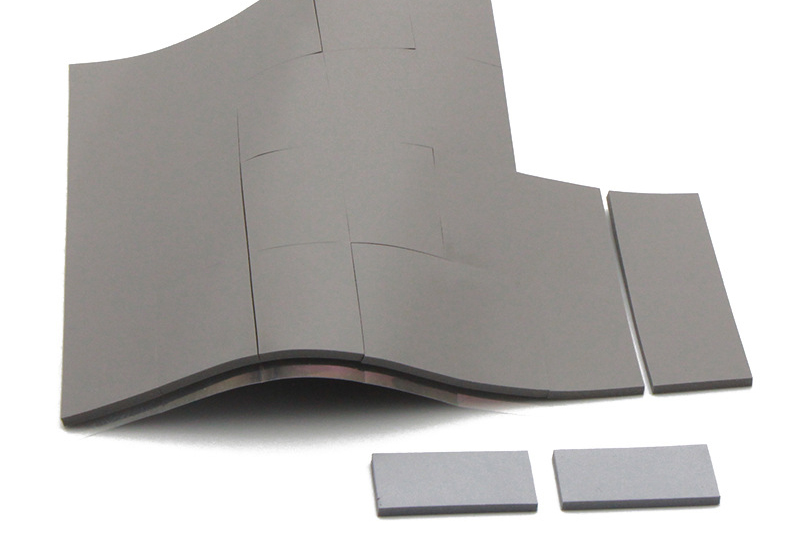

thermal silicone pad: It is a solid-state sheet and uniform thickness. It can be cut into the required shape or directly on the radiator. It is particularly suitable for occasions that are not convenient to apply silicone grease or need a large area of heat transmission. Silicon pad installation is easy, no additional cleanup is needed.

2. Thermal conductivity and adaptability:

Thermal silicone grease: It usually has a higher thermal conductivity (1.0 ~ 5.0W/m.k). It is excellent in heat dissipation. It is suitable for components that need to be disassembled and maintained frequently.

Thermal conductive pad: The range of thermal conductivity is wide (1.2 ~ 12.8 w/m.k). Although the thermal conductivity of some high-end silicone pad is comparable to silicon grease, overall, the unit area of thermal silicone grease is usually stronger. Thermal Silicon pads are more suitable for stable and uniform heat transfer, and have a certain amount of tolerance for assembly tolerance.

3. Mechanical stability and reliability:

Thermal silicon grease: Because it is a non-curing material, long-term use may cause thickness or small displacement due to thermal circulation, vibration and other factors, and need to be checked and re-applied regularly.

Thermal silicone pad: It has good mechanical stability. It will not occur significantly in long-term use, and it has a certain adhesion force. It can ensure that long-term tight contact between the radiator and the heating elements will be kept close to the heat resistance.

4. Insulation performance and application range:

Thermal silicon grease: It usually has good insulation, but some silicone grease containing metal fillers may have a certain impact on the insulation performance. It is suitable for scenes that are not particularly high in insulation requirements.

Thermal silicone pad: often has better insulation performance, and is more suitable for electronic equipment and environment that requires strict insulation requirements.

In summary, thermal silicone pad can replace silicone thermal grease in many cases, especially in applications that need to simplify the assembly process, ensure long-term stable contact, avoid uneven application or overflow, and need good insulation. However, for the occasions that require high heat dissipation efficiency, the gap between the heating source and the heat dissipation device, or the need to be disassembled and maintained frequently, thermal silicon grease may be more ideal due to its excellent thermal conductivity and flexible application characteristics, which may be more ideal choose.

Therefore, when choosing to use thermal silicon pad instead of thermal silicone grease, it is necessary to fully consider the heat dissipation requirements, assembly conditions, maintenance convenience, and requirements for insulation performance in practical applications. Sometimes, according to the specific design of the equipment, even thermal silicone grease and thermal silicon pad may be used at the same time to make full use of their respective advantages to achieve the best heat dissipation effect.

CN >

CN >