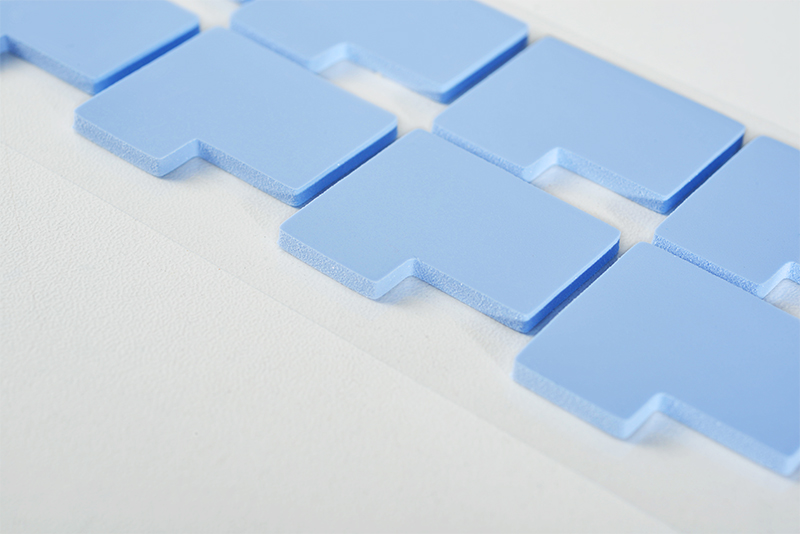

The Role of Silicone Thermal Conductive Pads — The Key Material That Keeps Devices “Cool and Stable”

In modern electronic devices, the more powerful the performance, the more severe the heat problem becomes. Whether it’s high-speed chips, power modules, or automotive control units, all require efficient and reliable thermal management solutions. Among many thermal interface materials, silicone thermal conductive pads stand out for their excellent thermal conductivity, flexibility, and stable electrical insulation properties — serving as a critical bridge between heat sources and heat sinks.

Core Functions of Silicone Thermal Conductive Pads

A silicone thermal conductive pad is a polymer-based thermal interface material (TIM) made from silicone filled with thermally conductive particles.

Its main functions can be summarized as follows:

1. Enhancing Heat Transfer Efficiency

Surfaces between electronic components and heat sinks are never perfectly smooth — microscopic air gaps exist, and air is a poor thermal conductor. The soft and compressible nature of silicone thermal conductive pads allows them to fill these gaps, significantly reducing thermal resistance and enabling efficient heat transfer.

2. Providing Electrical Insulation

In many applications, components not only need heat dissipation but also electrical isolation. Silicone thermal conductive pads feature excellent dielectric strength, preventing short circuits and leakage, ensuring system safety.

3. Cushioning and Vibration Damping

The inherent elasticity of silicone materials provides mechanical cushioning, minimizing stress caused by thermal cycling or vibration, thereby extending the component’s lifespan.

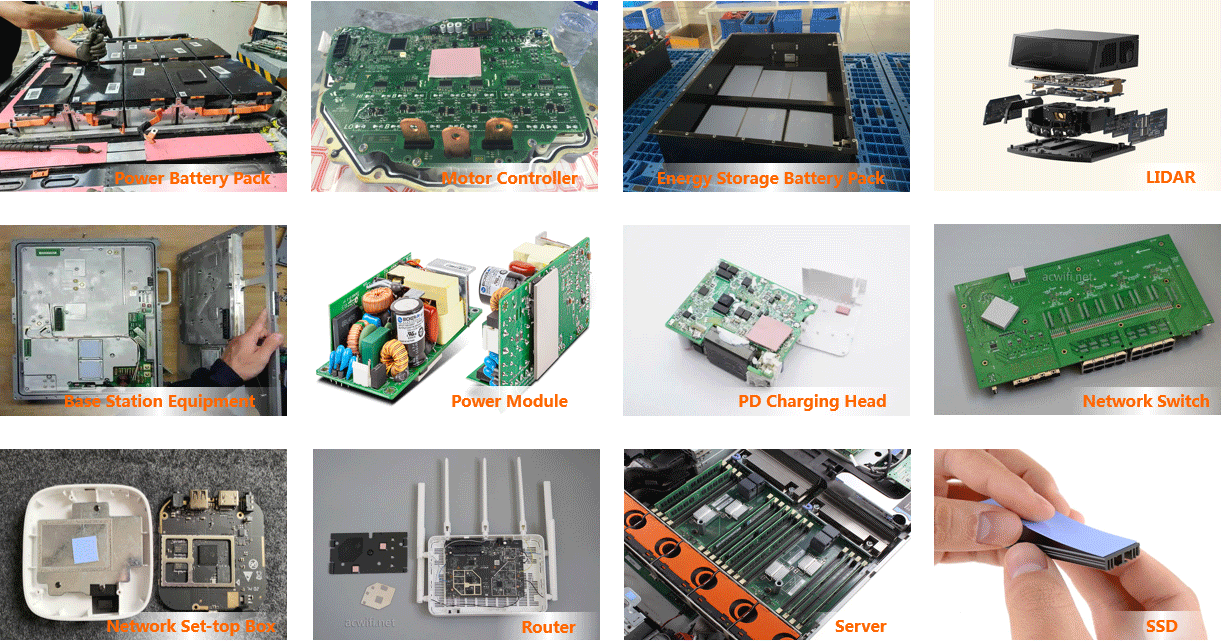

Application Fields of Silicone Thermal Conductive Pads

As device integration and power density continue to increase, silicone thermal conductive pads have become indispensable across various industries:

● Consumer Electronics: Laptops, tablets, smartphones, gaming consoles.

● Automotive Electronics: Battery systems, BMS, LED headlights, radar, ECU.

● Telecommunications: 5G base stations, optical modules, servers, power amplifiers.

● Industrial Equipment: Inverters, power supplies, control boards.

● Security & Surveillance: Cameras, infrared imaging systems.

In these scenarios, silicone thermal conductive pads are favored for their consistent conductivity, ease of assembly, dielectric insulation, and environmental durability — making them a reliable choice for demanding applications.

Key Factors Affecting Performance

Several factors determine the overall performance of a silicone thermal conductive pad:

1. Thermal Conductivity

Measured in W/m·K, higher values indicate better heat transfer. Depending on application, the range can vary from 1.0 to 15.0 W/m·K.

2. Hardness and Compressibility

Softer pads conform better to uneven surfaces, reducing thermal resistance; harder materials are suitable where structural support is needed.

3. Thickness and Compression Pressure

Proper selection of thickness and assembly force is critical. Pads that are too thick increase resistance, while those too thin may fail to fill gaps completely.

4. Reliability and Environmental Resistance

High-quality pads must exhibit excellent thermal stability, aging resistance, and UL94 V-0 flame retardancy for long-term reliability.

The Value of Silicone Thermal Conductive Pads in Heat Management Systems

In thermal design, a silicone thermal conductive pad is far from a “minor accessory.” It is a key component that determines overall heat management reliability.

When correctly selected and applied, it delivers multiple benefits:

● Enhanced System Stability and Performance

Maintaining optimal operating temperatures improves device efficiency and prevents thermal throttling.

● Extended Service Life

Effective heat dissipation reduces thermal fatigue and material degradation, improving reliability.

● Optimized Structure and Cost Efficiency

Proper thermal design allows smaller heat sinks or reduced fan power, achieving compactness and energy savings.

Conclusion: Let Heat Flow in Order, Let Devices Stay Cool

In thermal management, the importance of a silicone thermal conductive pad is often underestimated — yet it serves as the bridge that connects heat sources to cooling components, ensuring efficient heat transfer and stable operation.

As power electronics and intelligent devices evolve, silicone thermal conductive pads will continue to play a vital role in next-generation systems, providing stable, safe, and efficient “cooling power” for the modern electronic world.

CN >

CN >