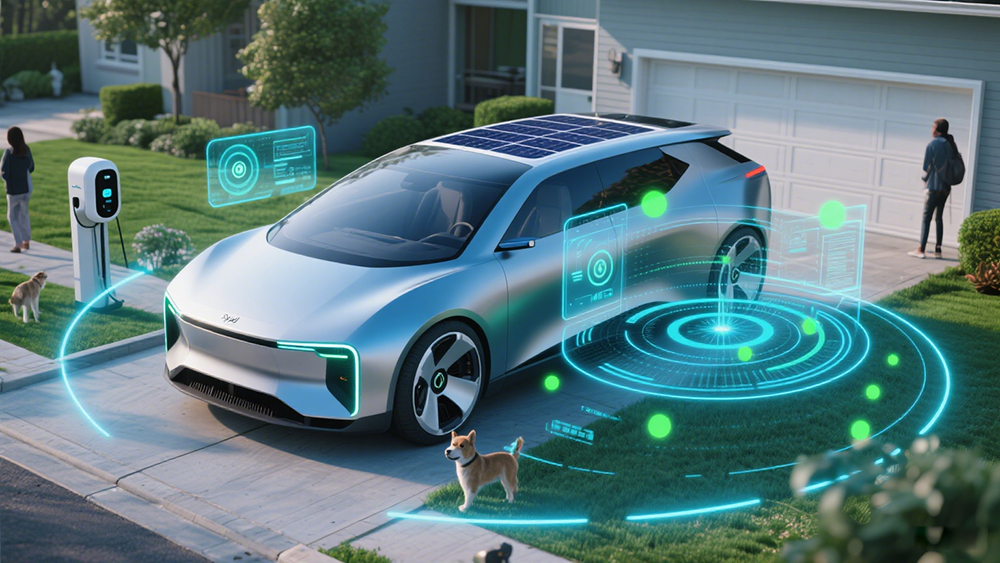

As intelligent driving technologies continue to advance rapidly, Advanced Driver Assistance Systems (ADAS) have become a key feature in modern vehicles. From adaptive cruise control to automatic emergency braking, ADAS is evolving from simple driver support to autonomous decision-making. However, behind the scenes of these highly integrated, high-performance systems lies an often-overlooked but critical component—Thermal Interface Materials (TIMs).

These materials may be inconspicuous, but they form the foundation of efficient thermal paths and are essential to ensuring system reliability.

What is ADAS and Why is Thermal Management Essential?

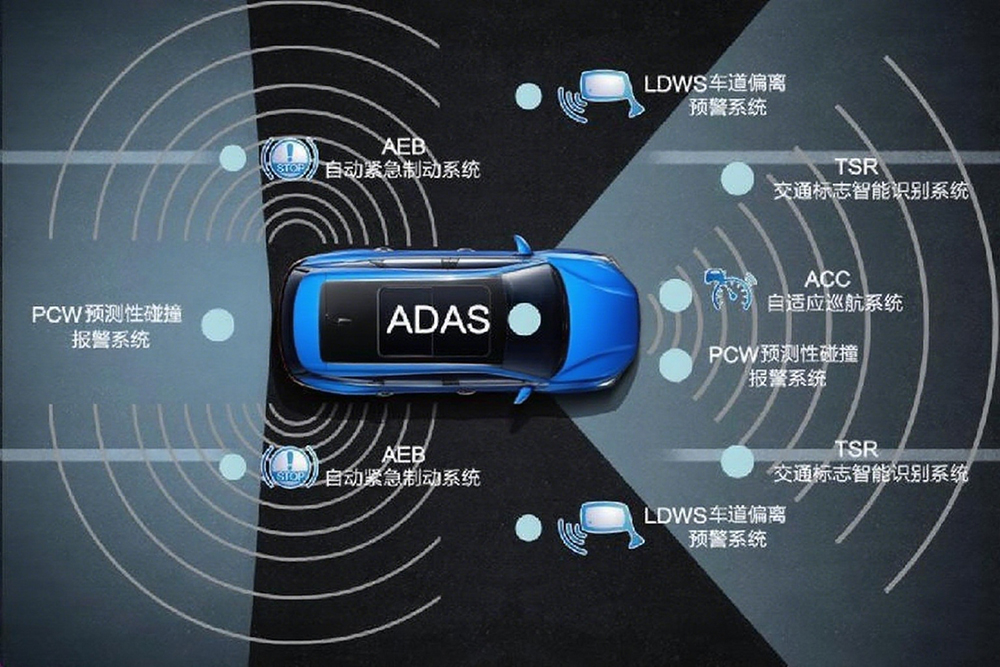

ADAS (Advanced Driver Assistance Systems) is a collection of technologies aimed at improving vehicle safety, comfort, and intelligence through the integration of sensing, computing, and control systems.

ADAS Architecture:

● Sensing Layer: Cameras, millimeter-wave radars, LiDAR, ultrasonic sensors, collecting real-time environmental data.

● Decision Layer: Domain controllers and central computing platforms processing massive sensor inputs and making real-time decisions.

● Execution Layer: Actuators such as braking, steering, and power systems executing the control commands.

Common ADAS Functions:

● Adaptive Cruise Control (ACC)

● Lane Keeping Assist (LKA)

● Automatic Emergency Braking (AEB)

● Automated Parking Assist (APA)

● Blind Spot Detection (BSD)

● Traffic Sign Recognition, Pedestrian Detection, etc.

As the industry moves toward L2+ and L3 autonomous driving, the computation load and thermal stress of ADAS systems are rising sharply.

The Hidden Heat Challenge in ADAS Systems

High-performance components in ADAS generate significant heat, such as:

● CMOS image sensors and ISP chips

● Radar and LiDAR processors

● SoCs, GPUs, and FPGAs in central computing platforms

● Power management modules

Consequences of Poor Thermal Management:

● Performance Degradation: Thermal throttling slows down computation and affects response time.

● Hardware Failures: Continuous high temperatures accelerate component aging.

● Thermal Drift: Sensor accuracy is compromised.

● System Risks: Overheating may cause ADAS malfunction, posing safety hazards.

Effective thermal design is essential not just for efficiency but also for safety.

Thermal Interface Materials: The Key to Efficient Heat Transfer

TIMs fill microscopic air gaps between heat sources and heat sinks, reducing thermal resistance and facilitating efficient heat transfer.

Common TIM Types:

|

Type |

Form |

Key Features |

Application Area |

|

Sheet |

Soft, compressible, electrically insulating |

Camera modules, radar shells |

|

|

Paste/Dispense |

High thermal conductivity, automation-friendly |

Radar control units, AI chips |

|

|

Thermal Greases |

Liquid |

Cost-effective, flexible application |

Mid-power control boards |

|

Phase Change Materials |

Solid/Semi |

Temperature-stabilizing, high heat flux |

SoC cooling channels |

|

Thermal-EMI Materials |

Sheet/Dispense |

Thermal conductivity + EMI shielding |

Radar, high-speed communication |

Typical TIM Applications in ADAS Systems

1. Camera Modules

● Heat Sources: CMOS sensors, ISP chips

● Goal: Maintain image accuracy

● Recommended: Electrically insulating thermal pads

2. Millimeter-Wave Radar

● Heat Sources: Power amplifiers, processors

● Goal: Prevent signal degradation

● Recommended: High thermal conductivity gels or EMI-absorbing TIMs

3. LiDAR

● Heat Sources: Laser emitters, control circuits

● Goal: Prevent thermal drift

● Recommended: Dispensed gel or dual-function TIMs

4. Central Computing Units

● Heat Sources: SoC/GPU, power modules

● Goal: Ensure continuous computing power

● Recommended: Gel + vapor chamber + heat sink

5. Power Modules

● Heat Sources: DC-DC converters

● Goal: Stable power supply

● Recommended: Grease or thin thermal pads

Selection Guidelines and Industry Trends

Key Selection Criteria:

|

Criteria |

Recommendations |

|

Thermal Conductivity |

≥ 3.5 W/m·K standard; ≥ 5.0 W/m·K for high-power areas |

|

Operating Temperature |

-40°C to 150°C; automotive-grade compliance |

|

Electrical Insulation |

Essential for preventing short circuits |

|

Compressibility |

Ensures close contact between uneven surfaces |

|

Process Compatibility |

Suitable for automation (dispensing, tape, lamination) |

|

Reliability Testing |

Meets AEC-Q100, ISO 16750, and other automotive certifications |

Development Trends:

1. Higher Conductivity, Thinner Form Factors: To handle denser heat loads.

2. Functional Integration: Thermal + EMI shielding in one material.

3. Manufacturing Friendliness: Gels and PCMs suited for automation.

4. Platform Customization: Modular TIM selection based on component needs.

Conclusion: TIMs—The Unsung Heroes of ADAS Reliability

As ADAS continues to grow in complexity and importance, ensuring stable thermal conditions becomes mission-critical. While processors, sensors, and algorithms steal the spotlight, thermal interface materials quietly support system reliability from behind the scenes.

These tiny materials play a crucial role in every sensor response, every millisecond of computation, and every safe maneuver. In the era of intelligent driving, TIM innovation will be a foundational force driving performance and safety forward.

CN >

CN >