How Thermal Silicone Pads Enable Precise Temperature Control in Oscilloscopes

Introduction: From Signal Accuracy to Thermal Stability

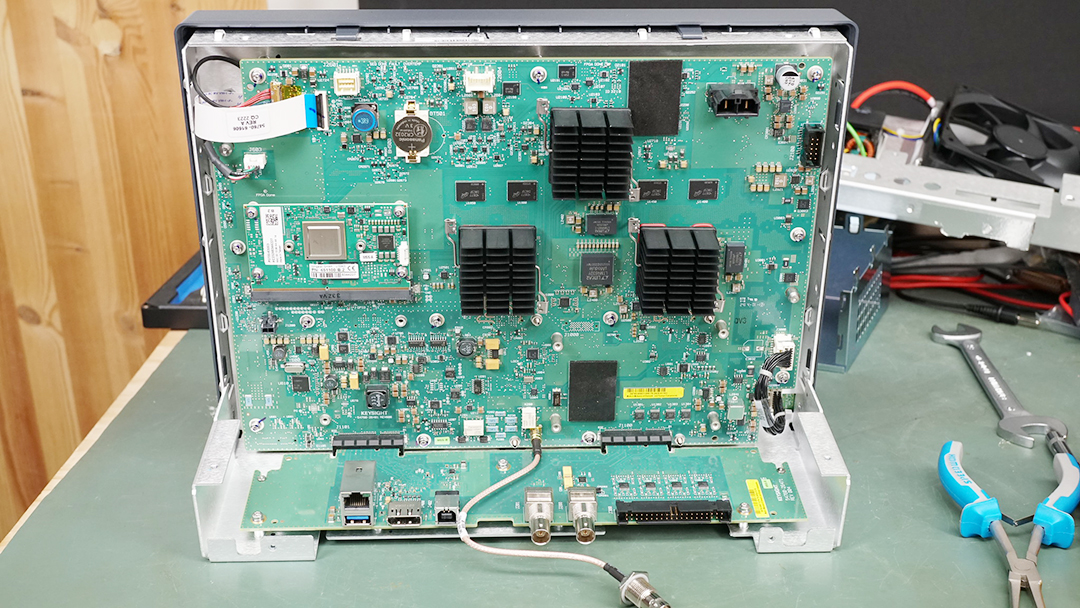

In high-frequency electronic testing equipment, oscilloscopes play a critical role in signal acquisition and waveform analysis. Their performance stability directly determines the accuracy of measurement results. As bandwidth and sampling rates continue to increase, internal components such as high-speed ADCs, signal processing modules, and power units generate significant heat. Effectively managing this heat within a compact space has become a core challenge for design engineers.

Against this backdrop, thermal silicone pads have become indispensable in oscilloscope thermal management systems, thanks to their superior thermal conductivity, electrical insulation, and flexible conformability.

Thermal Management Challenges in Oscilloscopes

Oscilloscopes face unique thermal management challenges characterized by high power density, localized heat sources, and compact internal layouts:

1. Concentrated Heat in High-Density Chips

Core components such as high-frequency amplifiers, ADC modules, and FPGAs often produce localized hotspots under continuous high-load operation, affecting accuracy and lifespan.

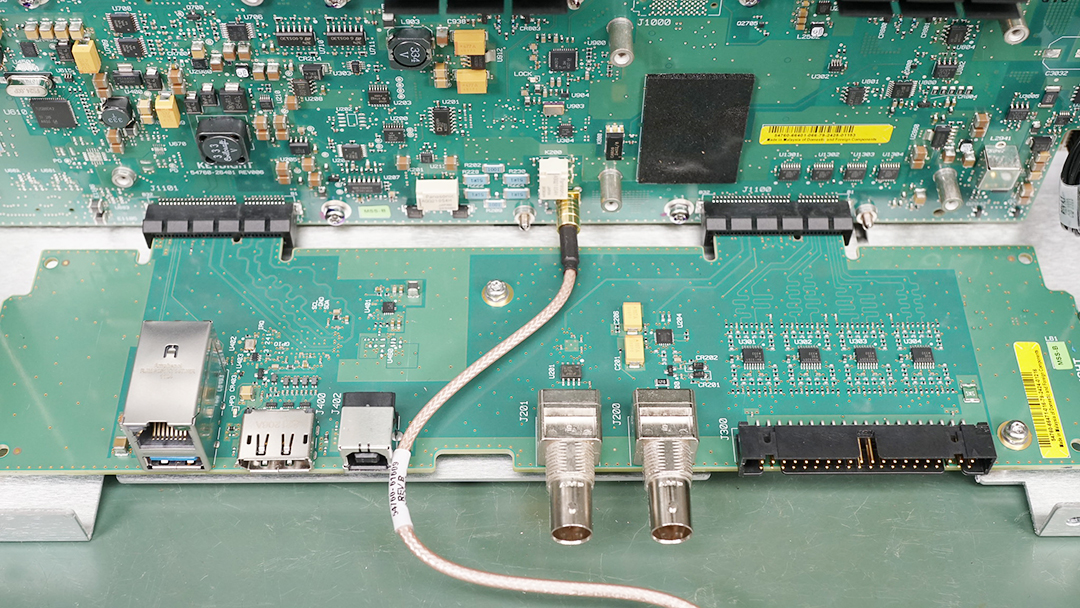

2. Limited Space and Restricted Heat Paths

The compact internal design limits airflow, making traditional air cooling insufficient for uniform heat dissipation.

3. Dual Demand for Insulation and Thermal Conductivity

High-voltage isolation and signal interference risks require materials that combine excellent dielectric strength with stable thermal performance.

4. High Reliability Under Continuous Operation

As oscilloscopes often run continuously for extended periods, thermal interface materials must exhibit superior aging resistance, compression durability, and interface stability.

Advantages and Suitability of Thermal Silicone Pads

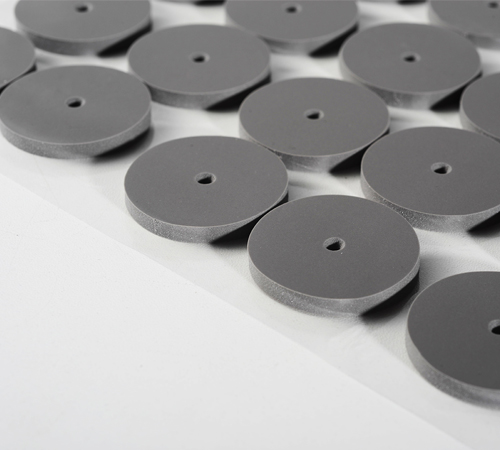

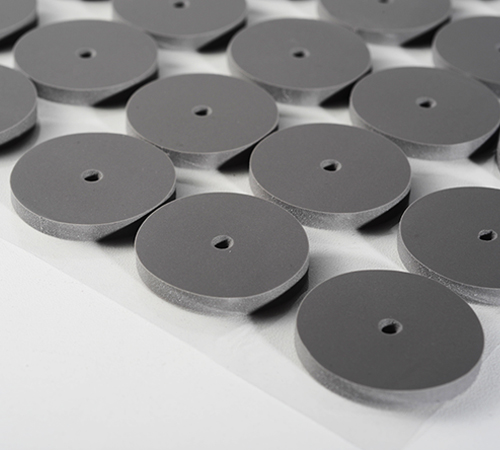

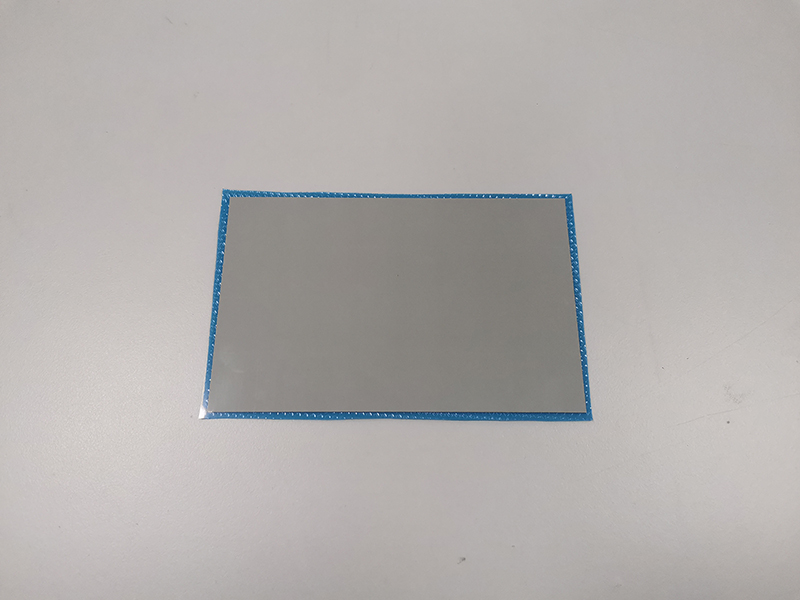

Thermal silicone pads are made by embedding high-conductivity fillers (e.g., alumina, boron nitride) into a silicone matrix, creating a material that conducts heat while providing electrical insulation. Their core advantages include:

1. High Thermal Conductivity and Low Thermal Resistance

With conductivity ranging from 1.0 to 12.0 W/m·K, they effectively reduce thermal resistance between chips and heat sinks, improving thermal transfer efficiency.

2. Excellent Flexibility and Compressibility

They conform tightly to uneven surfaces, eliminating air gaps and ensuring consistent heat transfer.

3. Electrical Insulation and Safety Protection

Their high dielectric strength ensures safe isolation between high-voltage modules and prevents signal interference or breakdown.

4. Outstanding Thermal Stability

Capable of operating reliably between -40℃ and 150℃, they meet the long-term stability demands of oscilloscope systems.

5. Ease of Assembly and Maintenance

Available in various thicknesses and hardness levels, they support automated assembly and easy replacement during servicing.

Typical Application Scenarios

Within oscilloscopes, thermal silicone pads are typically applied in the following areas:

● Between ADC Modules and Heat Sinks: Reduce thermal resistance in high-speed sampling circuits and enhance signal precision.

● On FPGA and DSP Components: Efficiently dissipate heat from high-density computational units to prevent thermal drift.

● Between Power Modules and Enclosures: Provide electrical insulation while conducting heat away from power circuitry.

● Between Input Amplifiers and Structural Frames: Balance thermal gradients and minimize temperature-induced signal deviation.

By selecting appropriate pad thickness (0.3–10mm) and hardness (Shore 00 30–70), designers can achieve optimal balance between mechanical stress and thermal efficiency.

Case Study: Performance Verification

A leading test equipment manufacturer adopted NFION NF150-500 high thermal conductivity silicone pad (5W/m·K) to replace conventional thermal pads in a high-bandwidth oscilloscope project. The results were significant:

● Core chip temperature decreased by approximately 12℃, ensuring more uniform heat distribution;

● Signal stability improved by about 8%, significantly reducing sampling error;

● System reliability extended to over 2000 hours of continuous operation without failure;

● Assembly efficiency increased by 25%, simplifying maintenance procedures.

These results clearly demonstrate the superior performance and reliability of NFION NF150-500 thermal silicone pads in oscilloscope thermal management.

Conclusion: Material Innovation Drives Measurement Accuracy

As oscilloscopes evolve toward higher frequencies and greater integration, thermal management has shifted from a secondary concern to a core factor influencing system performance and reliability.

With high thermal conductivity, excellent conformability, electrical insulation, and long-term stability, thermal silicone pads have become essential thermal interface materials in precision instruments.

In the future, as high-speed data acquisition, 5G communication, and AI-driven testing continue to expand, NFION NF150-500 will play an increasingly vital role — not only as an “invisible supporter” of heat transfer, but as a cornerstone ensuring signal accuracy and equipment longevity.

CN >

CN >