Learn the Differences Between Thermal Conductivity and Heat Transfer Coefficient

In thermodynamics and heat transfer, thermal conductivity and heat transfer coefficient are two critical concepts, often confused or thought to be the same. However, these two coefficients differ significantly in definition, application, and physical meaning. This article will delve into the differences between thermal conductivity and heat transfer coefficient, explaining their basic concepts, calculation methods, influencing factors, and practical applications to help readers fully understand these important parameters.

Thermal Conductivity

Basic Definition

Thermal conductivity (commonly denoted as ( k )) is a material property that describes the ability of a material to conduct heat under steady-state conditions. It defines the amount of heat that passes through a unit area of the material per unit time, given a unit temperature gradient. When there is a temperature difference across a material, heat transfers from the high-temperature side to the low-temperature side, and thermal conductivity measures this heat transfer capability.

Mathematical Expression

Thermal conductivity can be expressed through Fourier's Law of Heat Conduction:

q = -kdT/dx

where:

- q is the heat flux density (heat flow per unit area, unit: W/m²).

- k is the thermal conductivity (unit: W/m·K).

- dT/dx is the temperature gradient (unit: K/m).

The negative sign indicates that heat flows from the high-temperature region to the low-temperature region.

Influencing Factors

Thermal conductivity is influenced by several factors:

1. Material Properties: Different materials have different molecular structures and atomic interactions, leading to varying thermal conductivities. For example, metals like copper and aluminum have high thermal conductivities, while non-metals like wood and glass have low thermal conductivities.

2. Temperature: The thermal conductivity of most materials changes with temperature. Generally, the thermal conductivity of metals decreases with increasing temperature, while that of non-metals may increase.

3. Purity and Phase: The purity and phase (such as crystalline structure or amorphous state) of a material also affect its thermal conductivity.

Application Fields

Thermal conductivity is widely used in various engineering fields, such as:

- Building Materials: To evaluate the insulation performance of materials.

- Electronics Industry: For designing heat sinks and thermal management systems.

- Chemical and Metallurgical Industries: To analyze the thermal conduction efficiency of reactors and furnaces.

Heat Transfer Coefficient

Basic Definition

The heat transfer coefficient (commonly denoted as ( h )) describes the ability of heat transfer between a fluid and a solid surface. It not only considers the thermal conductivity of the material but also includes the effects of fluid flow and thermal convection. The heat transfer coefficient is a crucial parameter for describing the efficiency of convective heat transfer.

Mathematical Expression

The heat transfer coefficient is typically expressed through Newton's Law of Cooling:

q = h A (Ts - Tf)

where:

- q is the heat flow (unit: W).

- h is the heat transfer coefficient (unit: W/m²·K).

- A is the heat transfer area (unit: m²).

- Ts is the surface temperature of the solid (unit: K).

- Tf is the fluid temperature (unit: K).

Influencing Factors

The heat transfer coefficient is influenced by the following factors:

1. Fluid Properties: The viscosity, density, specific heat, and thermal conductivity of the fluid affect the heat transfer coefficient.

2. Flow State: The flow state of the fluid (laminar or turbulent) significantly affects heat transfer efficiency. Turbulent flow generally has a higher heat transfer coefficient.

3. Surface Characteristics: The roughness and shape of the solid surface also impact the fluid's heat transfer performance.

4. Temperature Difference: The temperature difference between the solid surface and the fluid affects the driving force for heat transfer.

Application Fields

The heat transfer coefficient is important in the following fields:

- Heat Exchanger Design: For optimizing the heat transfer efficiency of heat exchangers.

- Air Conditioning and Refrigeration: For evaluating the performance of condensers and evaporators.

- Automotive Industry: For designing engine cooling systems.

- Aerospace: For designing thermal protection systems.

Comparison of Thermal Conductivity and Heat Transfer Coefficient

Fundamental Differences

1. Nature:

- Thermal conductivity focuses on heat transfer within a single material, being an intrinsic property of the material related to its internal structure and properties.

- The heat transfer coefficient involves interface heat transfer, influenced by fluid flow and interface conditions.

2. Application Range:

- Thermal conductivity is primarily used to describe heat conduction within solids or between solids.

- The heat transfer coefficient is used to describe convective heat transfer between fluids and solid interfaces or between fluids.

3. Calculation Methods:

- Thermal conductivity is measured through experiments determining the heat flux density and temperature gradient under steady-state conditions.

- The heat transfer coefficient typically requires experiments or numerical simulations combined with actual working conditions for determination.

Case Study for Understanding

To better understand the difference between thermal conductivity and heat transfer coefficient, let's analyze the following example.

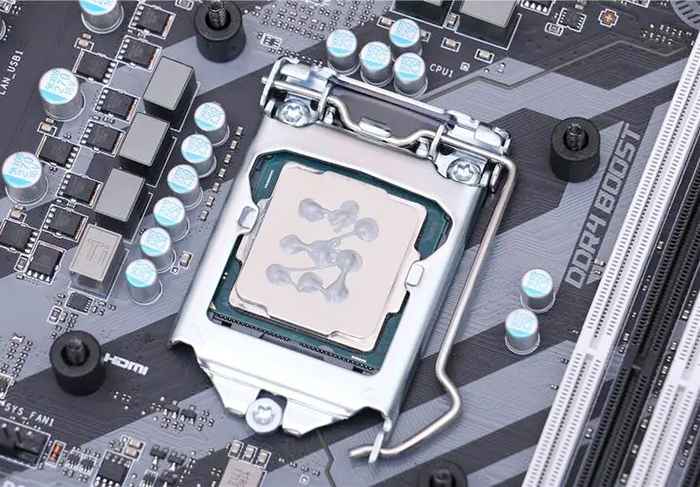

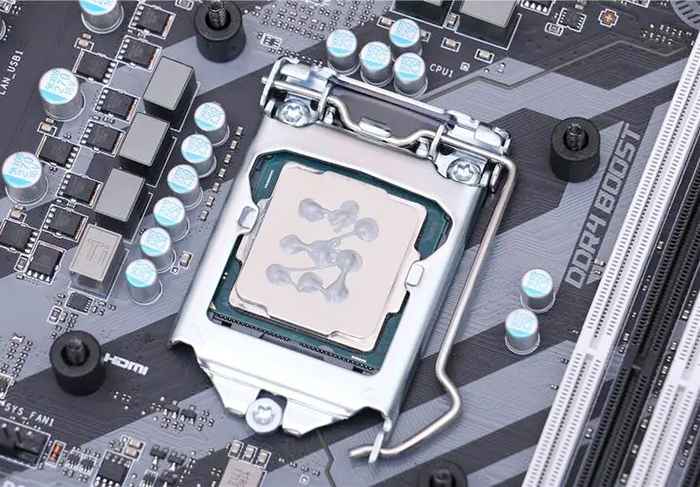

Suppose we are designing a heat sink to cool a heating electronic component. When selecting materials, we first consider the material's thermal conductivity, choosing one with a high thermal conductivity to quickly transfer heat from the component to the heat sink surface. However, considering only thermal conductivity is not enough; we must also consider the heat exchange between the heat sink and the surrounding air, involving the heat transfer coefficient. If the heat sink's surface design is unreasonable or air flow is inadequate, even a material with high thermal conductivity may not effectively dissipate heat, causing the component to overheat.

In heat exchangers, both thermal conductivity and heat transfer coefficient play roles. For instance, in a shell-and-tube heat exchanger, the tube wall material's thermal conductivity affects the efficiency of heat conduction between the internal and external fluids, while the heat transfer coefficient of the internal and external fluids determines the heat exchange capacity between the fluids and the tube wall. High thermal conductivity materials (like copper) improve heat conduction efficiency, and optimizing fluid flow (e.g., increasing turbulence) can significantly enhance the heat transfer coefficient.

Conclusion

Thermal conductivity and heat transfer coefficient are two distinct yet important concepts in heat transfer. Thermal conductivity reflects a material's inherent ability to conduct heat, while the heat transfer coefficient reflects the efficiency of heat transfer between a fluid and a solid interface. Understanding and distinguishing these two coefficients is crucial for engineering design and thermal management. In practical applications, engineers need to consider both material properties and fluid flow conditions to achieve optimal heat transfer. A thorough understanding of these concepts enables better design and optimization of thermal management systems, improving energy efficiency and equipment performance.

CN >

CN >