As the global shift toward clean energy accelerates, photovoltaic (PV) systems are rapidly integrating into both industrial and residential scenarios. Among their core components, the photovoltaic inverter plays a vital role in converting DC power into AC power. More importantly, it determines the overall efficiency, stability, and safety of the entire system. Yet, behind this critical component lies an often-overlooked element: the thermal interface pad, which is fundamental to ensuring effective heat dissipation and stable inverter operation.

This article explores the essential role thermal interface pads play in photovoltaic inverters, offering a comprehensive look at their technical function, application areas, and selection criteria—revealing the big impact of this seemingly small material.

Why Is Thermal Management in PV Inverters So Important?

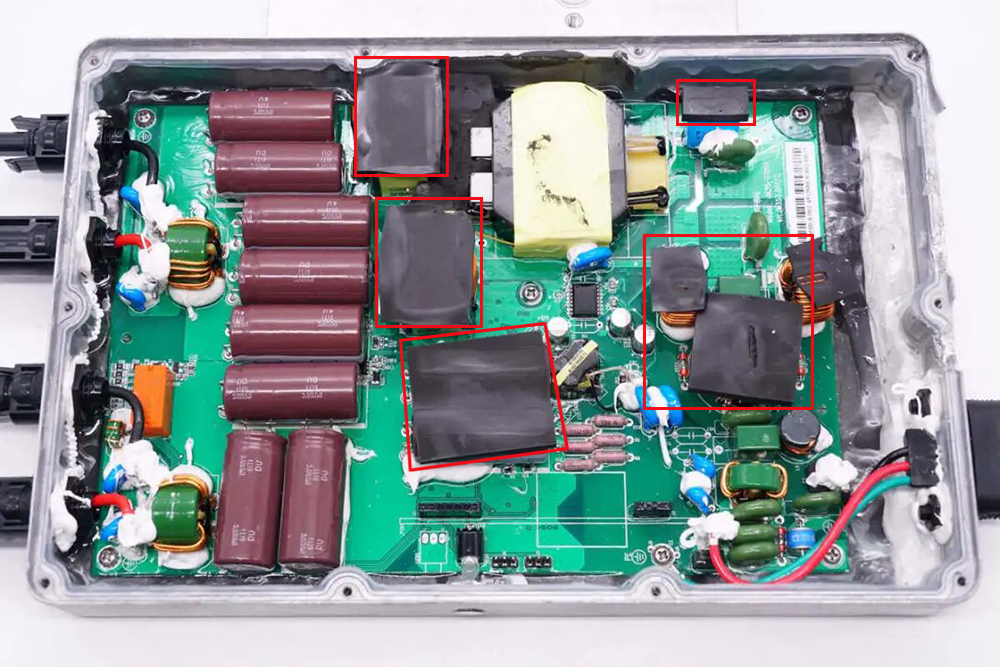

During the process of converting DC to AC, photovoltaic inverters involve numerous high-speed switching and rectifying electronic components—such as IGBTs (Insulated-Gate Bipolar Transistors), MOSFETs, driver circuits, inductors, and control chips—that generate a significant amount of heat over prolonged operation at high power levels.

If this heat is not effectively and promptly dissipated, the result may include:

● Overheating and degradation or failure of components

● Reduced conversion efficiency and higher energy loss

● Shortened product lifespan and increased maintenance costs

● Risk of thermal runaway under extreme weather, leading to safety issues

Thus, developing an efficient thermal management system is essential, and thermal interface materials (TIMs) are a critical part of the heat transfer path.

Thermal Interface Pads: The Core Interface Material for Inverter Cooling

1. What Are Thermal Interface Pads?

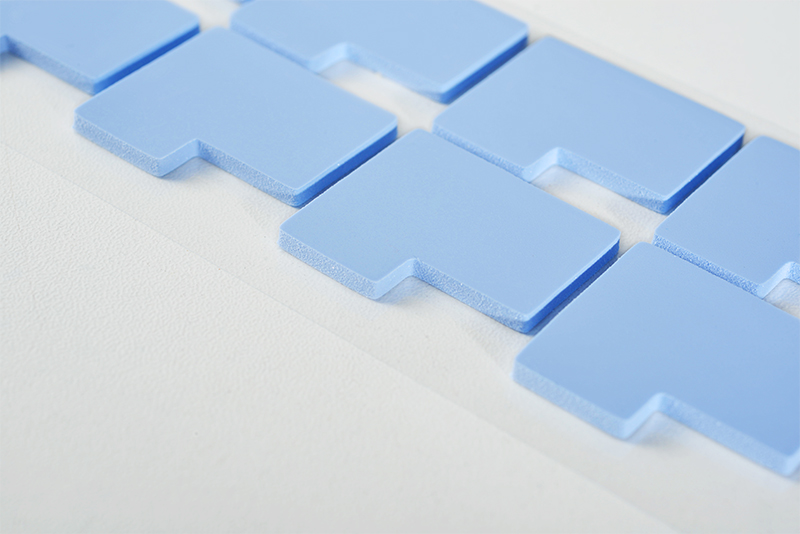

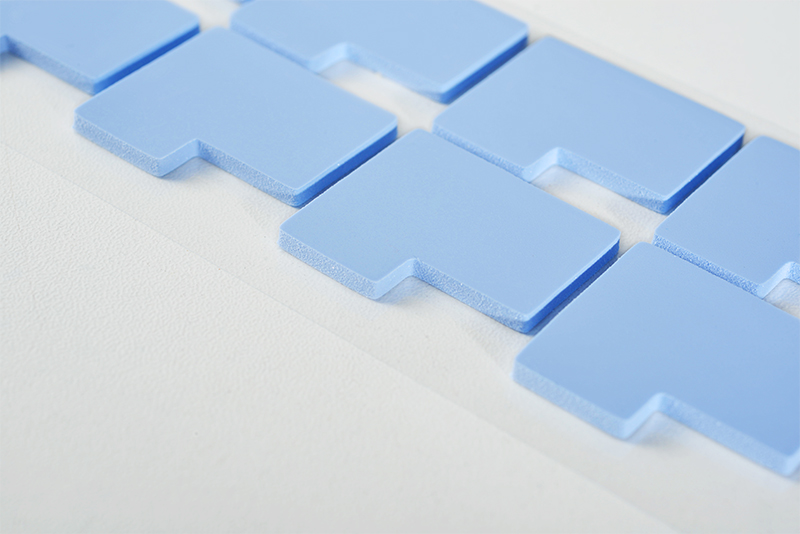

Thermal interface pads are soft, thermally conductive, and electrically insulating materials used to fill microscopic air gaps between heat-generating components and heat sinks (such as aluminum plates or cooling modules), effectively reducing thermal resistance and improving heat transfer.

Compared to traditional thermal grease, thermal pads offer several advantages:

● Easy installation without smearing

● Non-flowing, non-drying, and long-term stability

● Electrical insulation for safety

● Customizable in size and thickness for complex structures

2. Common Application Areas in PV Inverters:

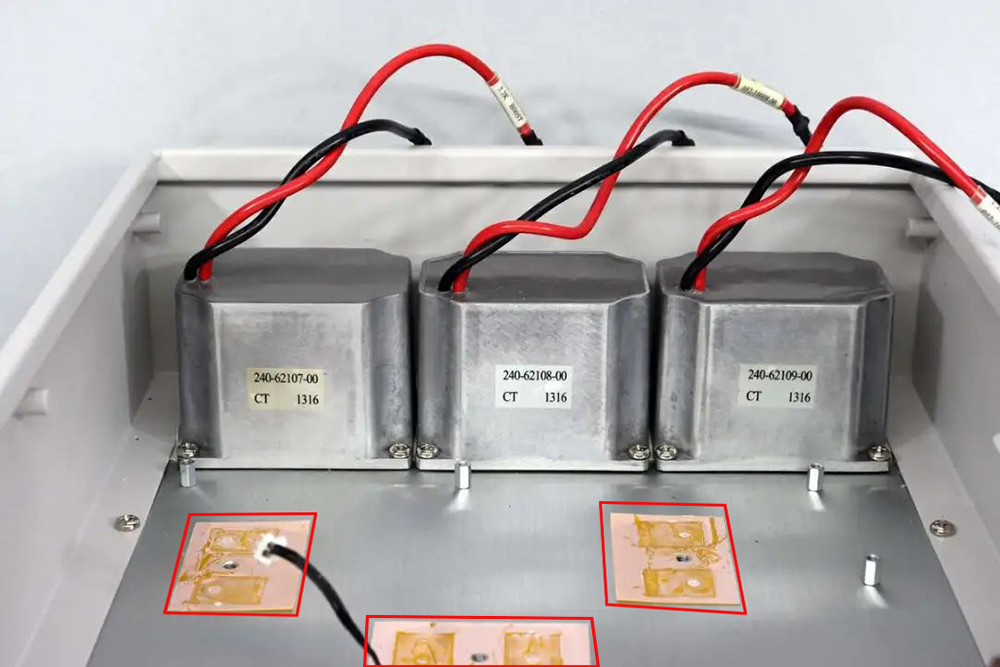

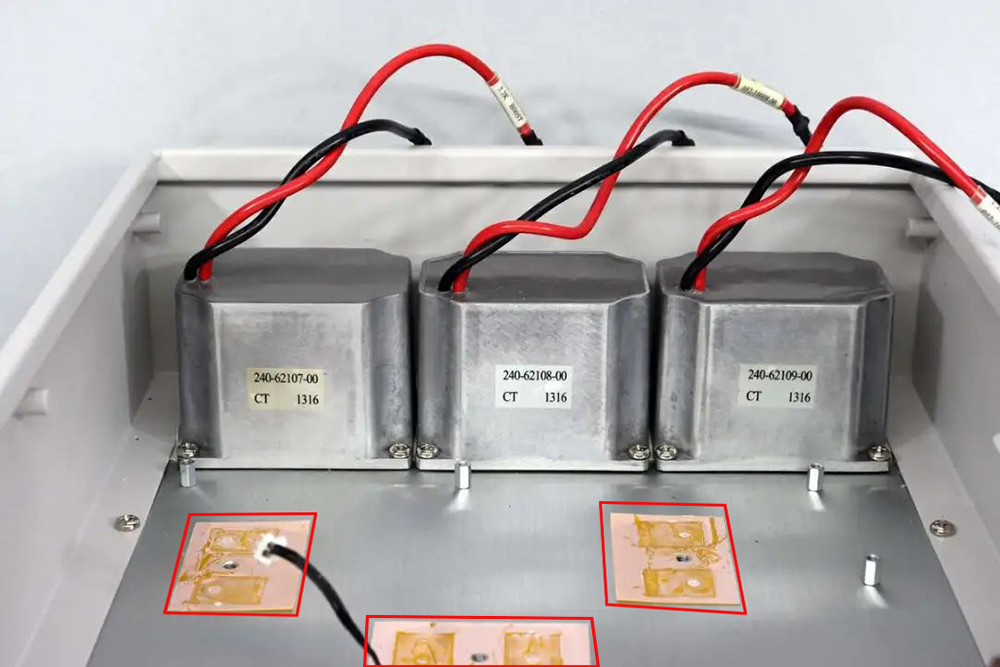

● Between IGBT modules and heat sinks: Facilitates rapid heat removal from high heat-density components

● Between inductors and aluminum casing: Fills air gaps to improve convective efficiency

● Between control chips and metal casing: Helps maintain chip temperature stability

● Between rectifiers and aluminum baseplates: Enhances consistency across thermal conduction paths

By optimizing these key thermal interfaces, thermal pads greatly improve heat control, reduce component temperatures, and extend the service life of the inverter.

Key Considerations When Choosing Thermal Interface Pads

When selecting thermal pads for inverter systems, it's not enough to focus solely on high thermal conductivity (W/m·K). A holistic evaluation is necessary, including:

1. Balancing Thermal Conductivity and Resistance

While high conductivity is important, the total thermal resistance (including pad thickness and contact quality) plays a more decisive role in actual performance.

2. Softness and Conformability

Materials must be soft enough to conform to uneven surfaces under pressure, improving contact and minimizing trapped air.

3. High-Temperature and Environmental Stability

Given that PV inverters often operate in hot, sun-exposed environments, pads must offer UV resistance, anti-aging properties, and durability under heat.

4. Electrical Insulation Performance

In high-voltage module applications, thermal pads should also deliver excellent dielectric strength and insulation reliability to prevent breakdown.

5. Certifications and Reliability Testing

Choose pads that meet UL94 V-0 flame retardancy, RoHS/REACH compliance, and have undergone tests like 85°C/85% RH aging and thermal shock cycles.

How PV Inverter Manufacturers Should Approach Thermal Pad Strategy

With the rise of high-integration, compact, high-power-density inverter designs, thermal management becomes more challenging. Manufacturers should adopt strategies such as:

● Thermal simulation and design during R&D stage

● Close collaboration with material suppliers for customized solutions

● Optimizing device layout and thermal paths from the module level

● Long-term reliability testing before mass production

Thermal pads are not just components—they embody a deeper thermal management philosophy.

Conclusion: Thermal Pads as the Inverter’s Invisible Guardian

When discussing PV inverter performance, longevity, and reliability, we often focus on circuit architecture or control algorithms. However, the quiet enabler working behind the scenes is often the thermal interface material. Thermal pads may be small, but they are essential for maintaining stable and efficient operation, especially under harsh outdoor conditions. As photovoltaic technology continues to evolve, their significance will only grow.

Choosing the right thermal material is like buying an invisible insurance policy for long-term inverter reliability.

Next time you see a photovoltaic inverter running efficiently, take a moment to appreciate the silent contribution of the thermal interface pad working faithfully inside.

For more information on thermal interface solutions in renewable energy systems, contact a professional thermal materials manufacturer for customized support and expert consultation.

CN >

CN >