Overview of UL Certification

UL (Underwriters Laboratories) is a globally recognized safety certification organization that primarily evaluates product safety, electrical performance, and flame resistance. UL certification is widely applied in industries such as electronics, electrical appliances, and mechanical equipment, especially for materials requiring electrical safety and flame-retardant properties.

For thermal conductive pads, whether UL certification is mandatory depends on their application fields, regulatory requirements, and customer demands. NFION Thermal will explore the significance of UL certification for thermal conductive pads and whether it is a compulsory requirement.

Major Application Fields of Thermal Conductive Pads

Thermal conductive pads, a type of high-polymer thermal interface material, are widely used in the electronics, power, telecommunications, automotive, and LED industries. They are primarily applied in the following scenarios:

1. Electronics Cooling: Used between processors, power modules, graphics cards, and storage devices to enhance heat dissipation efficiency and reduce operating temperatures.

2. New Energy Batteries: Applied between battery packs and heat dissipation structures to improve thermal management, ensuring safety and longevity.

3. Telecommunication Equipment: Used in base stations, servers, and high-performance devices to optimize heat conduction and prevent overheating.

4. LED Lighting: Applied in LED lamps to enhance heat dissipation, improve light efficiency, and extend lifespan.

5. Automotive Electronics: Essential in new energy vehicle control systems and IGBT modules, where stringent thermal management is required.

Different application scenarios impose varying performance requirements on thermal conductive pads. Safety concerns in these applications determine whether UL certification is necessary.

Importance of UL Certification for Thermal Conductive Pads

UL certification impacts thermal conductive pads in the following aspects:

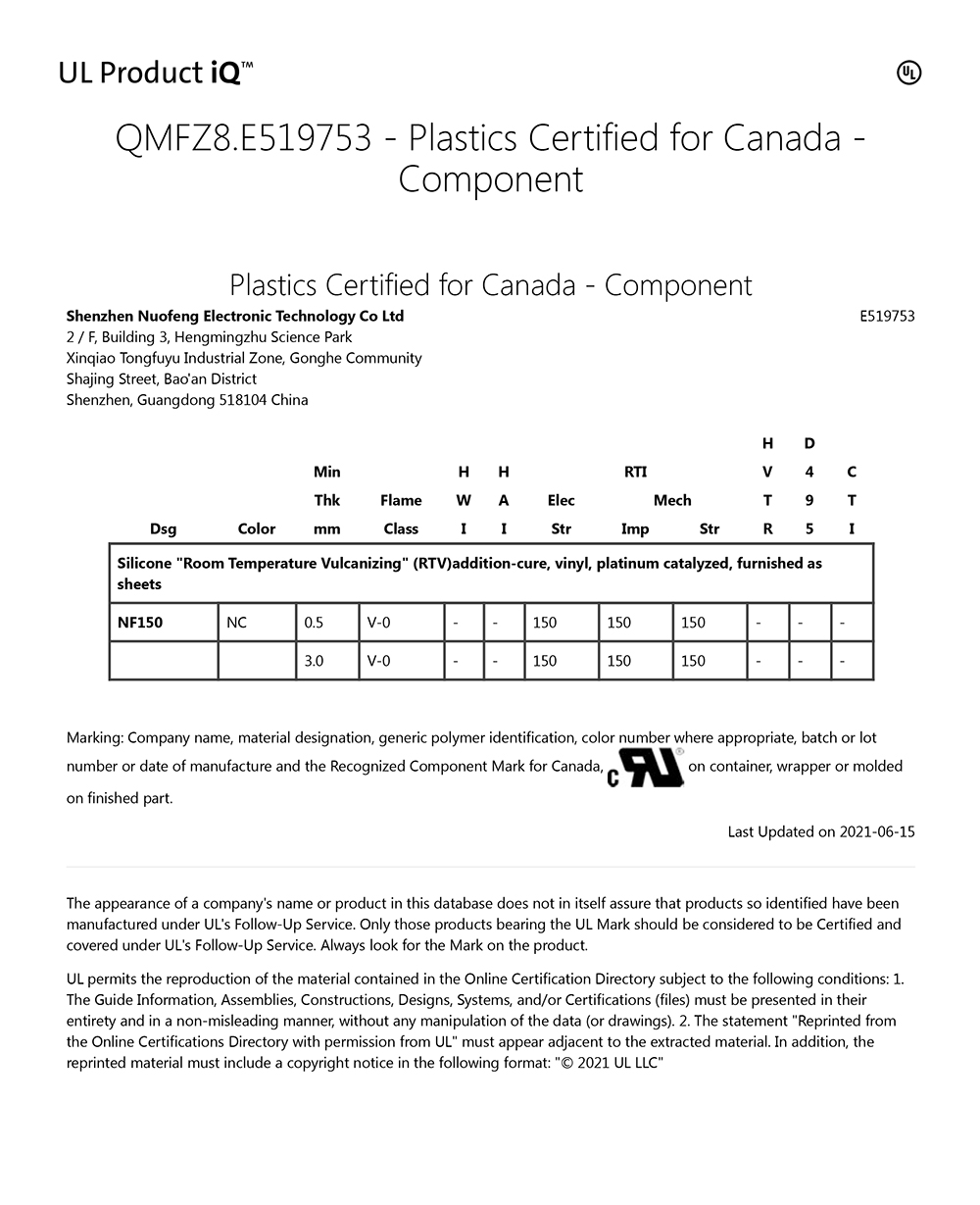

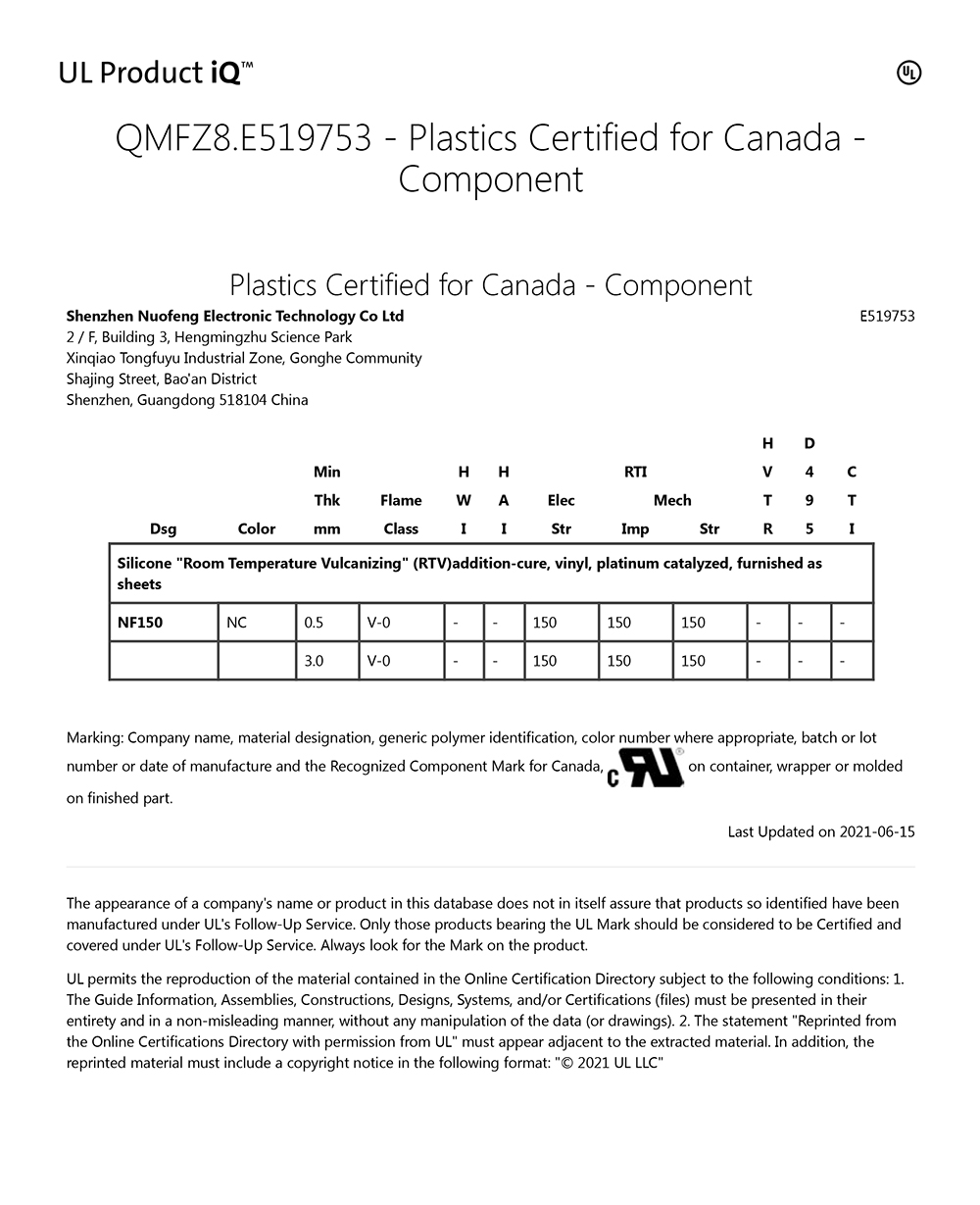

1. Flame Retardancy Requirements (UL 94 Standard)

Industries such as electronics, automotive, and telecommunications impose strict flame-retardant requirements. UL 94 is a commonly used standard for evaluating the flame resistance of plastic materials:

● UL 94 V-0: The highest flame retardant level; the material self-extinguishes quickly without dripping. Suitable for high-safety applications.

● UL 94 V-1/V-2: Slightly lower flame resistance than V-0, applicable to less critical environments.

● UL 94 HB: The lowest horizontal burning rating, used in non-safety-critical applications.

If a thermal conductive pad is used in high-safety environments such as servers, automotive electronics, or medical devices, it typically needs to comply with UL 94 V-0 to ensure fire safety under high temperatures or electrical failure.

2. Electrical Safety and Dielectric Strength (UL 746 Standard)

UL 746 assesses the electrical properties and safety of polymer materials, including dielectric strength and insulation performance. If thermal conductive pads are used in high-voltage applications (such as power electronics and transformers), they may need to comply with UL 746 to prevent electrical breakdown or short-circuit risks.

3. Market Access Requirements

● North American Market: UL certification is highly recognized, and many device manufacturers require thermal conductive pads to be UL-certified.

● European Market: The EU does not strictly mandate UL certification, but compliance with RoHS and REACH environmental regulations is essential.

● Chinese Market: UL certification is not legally required but is often obtained to enhance product competitiveness.

4. Customer and Industry Standards

Some customers (such as well-known electronics brands and automotive manufacturers) may require UL-certified thermal conductive pads as a procurement standard, especially for high-safety products like power supplies, automotive electronics, and servers.

Is UL Certification Mandatory for Thermal Conductive Pads?

1. Is It Mandatory?

UL certification is not a globally mandatory certification; it is more of an industry-recommended standard. Whether a thermal conductive pad requires UL certification depends on:

● Regulatory Requirements: Some industries or regions (e.g., North America) may indirectly require UL certification, such as compliance with UL 94 V-0 for electrical and electronic applications.

● Product Application: If the thermal conductive pad is used in safety-critical products (e.g., power supplies, automotive electronics, servers), UL certification is often required.

● Customer Requirements: If a client specifies UL certification, the supplier usually needs to provide certified materials to meet procurement standards.

2. When Is UL Certification Not Required?

If a thermal conductive pad is used in applications with low flame resistance and electrical safety requirements, such as general consumer electronics and standard LED lighting, UL certification may not be necessary. However, manufacturers may still choose to obtain certification to enhance product marketability.

Process for Obtaining UL Certification for Thermal Conductive Pads

If a manufacturer decides to apply for UL certification, the process generally includes the following steps:

1. Determine the Certification Category

Select the appropriate UL standard based on the product application, such as UL 94 (flame resistance), UL 746 (electrical safety), and UL 157 (sealing materials).

2. Sample Testing

Submit samples to a UL-accredited laboratory for flame resistance, electrical safety, and other performance evaluations.

3. Factory Inspection

UL conducts an on-site audit of the manufacturing facility to ensure product consistency.

4. Certification Approval

Upon passing the tests, UL issues a certification, allowing the product to bear the UL mark.

5. Regular Inspections

UL performs periodic factory audits to ensure continued compliance with certification standards.

Conclusion

Whether a thermal conductive pad requires UL certification primarily depends on its application field and customer requirements. For industries such as electronics, power, and automotive, compliance with UL 94 V-0 or similar standards is often necessary to ensure flame retardancy and market access. However, UL certification is not a universal legal requirement, and some consumer electronics products may not require it.

Companies should carefully evaluate regulatory compliance, market demands, and customer specifications when deciding whether to pursue UL certification, ensuring their products meet industry standards and enhance competitiveness.

CN >

CN >