Why Silicone Thermal Pads Need to Comply with ROHS Environmental Requirements?

Introduction

With the increasing global awareness of environmental protection, the environmental standards for electronic products are becoming more stringent. As an indispensable thermal management material in electronic devices, the environmental performance of silicone thermal pads has attracted significant attention. The ROHS (Restriction of Hazardous Substances) directive is an environmental regulation established by the European Union to limit the use of hazardous substances in electrical and electronic equipment. NFION Thermal will delve into why silicone thermal pads need to comply with ROHS environmental requirements, analyzing their importance and impact on the industry.

Background and Significance of the ROHS Directive

Origin of the ROHS Directive

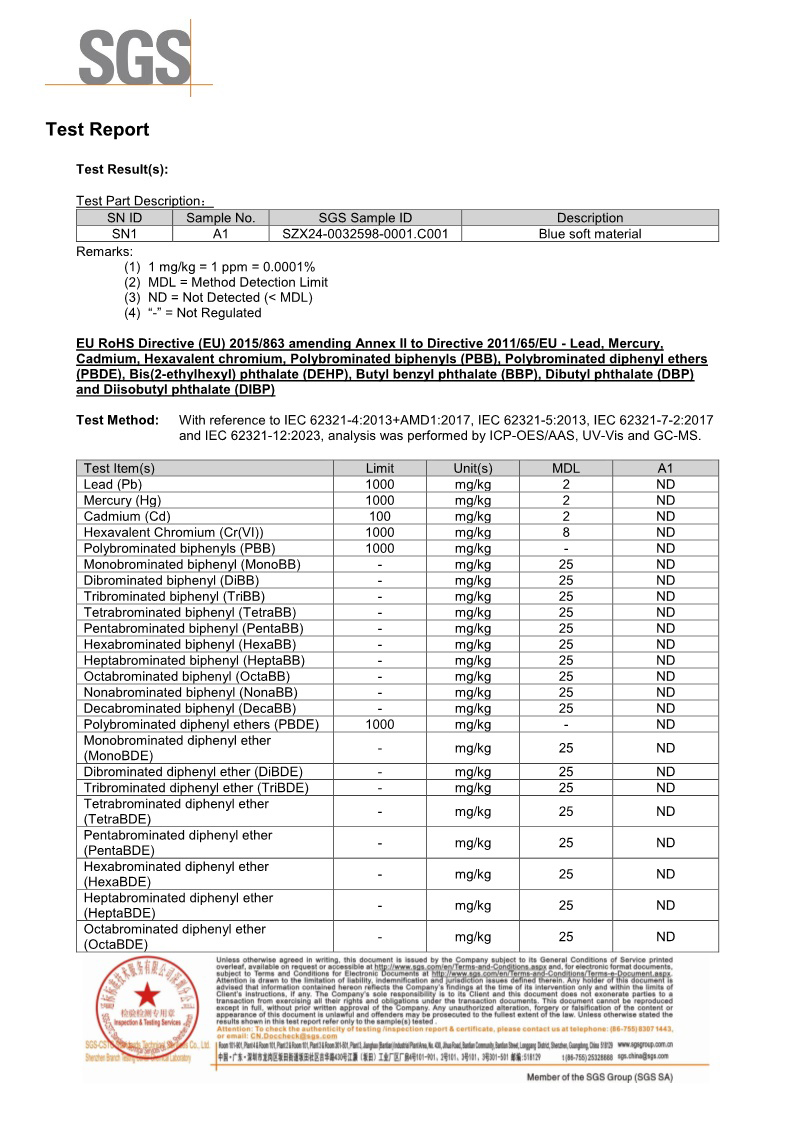

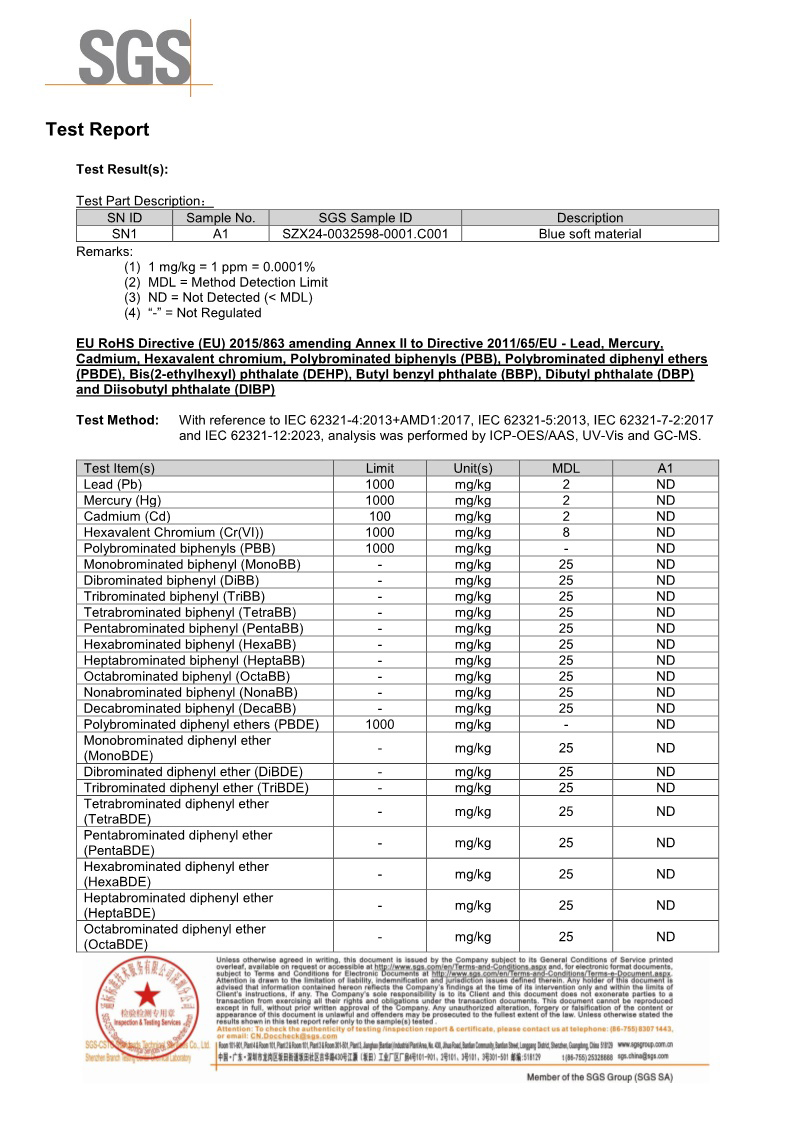

The ROHS directive was promulgated by the European Union in 2003 and officially implemented in 2006. It restricts the use of six hazardous substances in electrical and electronic equipment, including lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). These substances pose serious risks to the environment and human health, and the implementation of the ROHS directive aims to reduce the environmental pollution caused by electronic waste.

Global Impact of the ROHS Directive

Although the ROHS directive was initially implemented only within the European Union, its influence quickly expanded globally. Many countries and regions have adopted or referenced ROHS standards as the environmental benchmark for electronic products. As a result, compliance with ROHS requirements has become a necessary condition for electronic products to enter the international market.

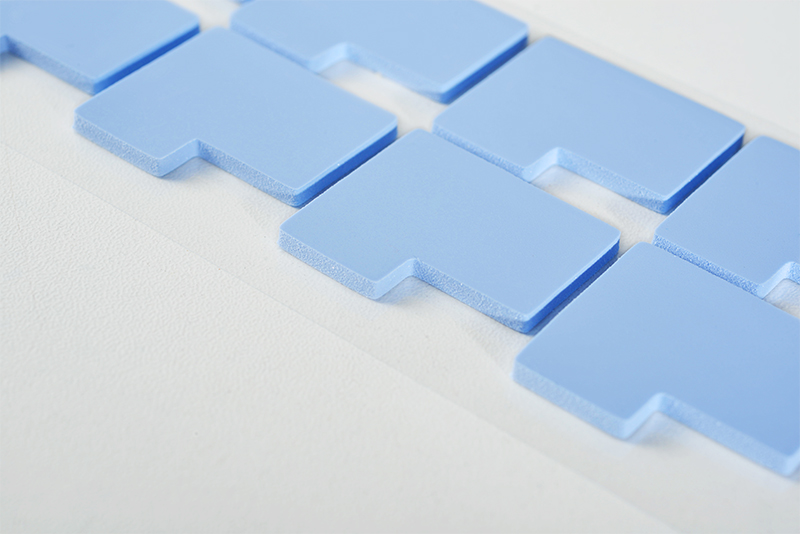

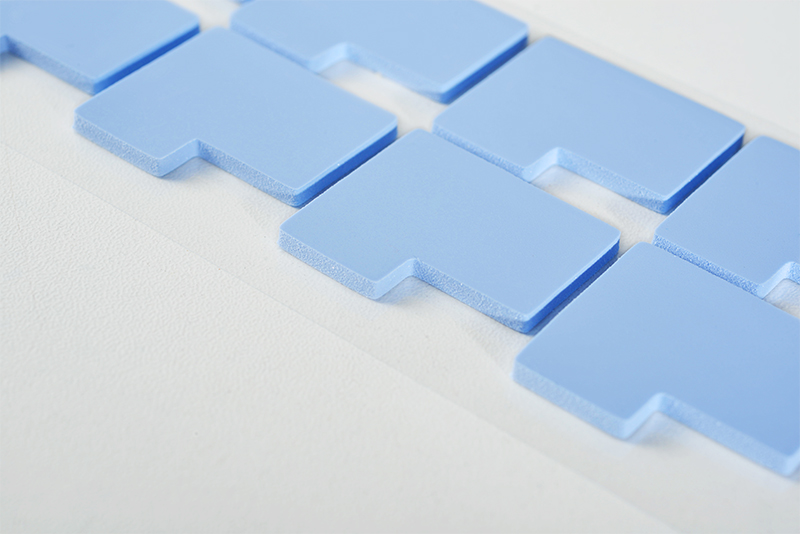

Functions and Characteristics of Silicone Thermal Pads

Functions of Silicone Thermal Pads

Silicone thermal pads are highly thermally conductive insulating materials widely used in the thermal management of electronic devices. Their main functions include:

1. Thermal Conductivity: Rapidly transferring heat generated by electronic components to heat sinks or casings to prevent device overheating.

2. Insulation: Providing electrical insulation to prevent short circuits and electrical failures.

3. Vibration Dampening: Absorbing mechanical vibrations to protect electronic components from physical damage.

Material Composition of Silicone Thermal Pads

Silicone thermal pads are typically composed of a silicone base and thermally conductive fillers. The silicone base provides flexibility and insulation, while the thermally conductive fillers (such as aluminum oxide, boron nitride, etc.) enhance thermal conductivity. However, traditional silicone thermal pads may contain hazardous substances restricted by the ROHS directive, such as lead and cadmium.

Necessity of Silicone Thermal Pads Complying with ROHS Requirements

Compliance with Environmental Regulations

Compliance with ROHS requirements is a primary condition for silicone thermal pads to enter the international market. The European Union and other regions adopting ROHS standards have strict regulations on the environmental performance of electronic products. Products that do not comply with ROHS requirements may face market access restrictions or even legal penalties. Therefore, manufacturers of silicone thermal pads must ensure their products meet ROHS standards to meet global market demands.

Environmental Protection and Sustainable Development

The core objective of the ROHS directive is to reduce environmental pollution caused by electronic waste. As an essential component of electronic devices, the environmental performance of silicone thermal pads directly affects the overall environmental performance of the product. ROHS-compliant silicone thermal pads do not contain hazardous substances, reducing pollution to soil, water, and air, and contributing to sustainable development goals.

Human Health and Safety

The hazardous substances restricted by the ROHS directive pose serious risks to human health. For example, lead and cadmium can cause neurological damage and cancer, while hexavalent chromium is highly carcinogenic. Silicone thermal pads are used in electronic devices over long periods, and if they contain these hazardous substances, they may harm human health through contact or volatilization. Therefore, ROHS-compliant silicone thermal pads not only protect the environment but also ensure consumer health and safety.

Enhanced Market Competitiveness

With increasing consumer awareness of environmental protection, environmentally friendly products are more competitive in the market. ROHS-compliant silicone thermal pads not only meet regulatory requirements but also enhance the market image and brand value of products. By providing environmentally friendly silicone thermal pads, manufacturers can gain more customer trust and support, strengthening their market competitiveness.

Challenges and Solutions for Silicone Thermal Pads Complying with ROHS Requirements

Technical Challenges

Compliance with ROHS requirements means that silicone thermal pads must not contain the six restricted hazardous substances, which imposes higher demands on material selection and manufacturing processes. For example, traditional thermally conductive fillers may contain lead or cadmium, requiring the development of environmentally friendly alternatives. Additionally, the manufacturing process must strictly control the introduction of hazardous substances to ensure the final product complies with ROHS standards.

Solutions

1. Development of Environmentally Friendly Materials: Research and develop new environmentally friendly thermally conductive fillers, such as lead-free aluminum oxide and cadmium-free boron nitride, to replace traditional hazardous materials.

2. Optimization of Manufacturing Processes: Improve production processes to reduce the use and emission of hazardous substances, ensuring products comply with ROHS requirements.

3. Strict Quality Control: Establish a comprehensive quality management system to rigorously test raw materials and finished products, ensuring compliance with ROHS standards.

Conclusion

As a critical thermal management material in electronic devices, the environmental performance of silicone thermal pads significantly impacts the overall environmental performance of the product. Compliance with ROHS requirements is not only a necessary condition for entering the international market but also a key factor in protecting the environment, ensuring human health, and enhancing market competitiveness. Facing technical challenges, manufacturers must ensure silicone thermal pads comply with ROHS standards through the development of environmentally friendly materials, optimization of manufacturing processes, and strengthened quality control, contributing to sustainable development.

Through this discussion, we have gained a deeper understanding of why silicone thermal pads need to comply with ROHS environmental requirements and recognized their importance in environmental protection, health, and market competitiveness. In the future, as environmental regulations become increasingly stringent, ROHS-compliant silicone thermal pads will become the mainstream choice in the industry, driving the electronics industry toward a more environmentally friendly and sustainable direction.

CN >

CN >