Thermal pads are crucial components in managing heat dissipation within electronic devices. With their ability to bridge the gap between heat-generating components and heat sinks, thermal pads ensure the efficient transfer of heat, preventing damage to sensitive components. Understanding the maximum temperature tolerance of thermal pads is essential for selecting the right pad for specific applications, especially in high-performance environments. NFION Thermal delves deeply into the factors influencing the maximum temperature of thermal pads, offering a thorough examination of the topic.

The Role of Thermal Pads in Heat Management

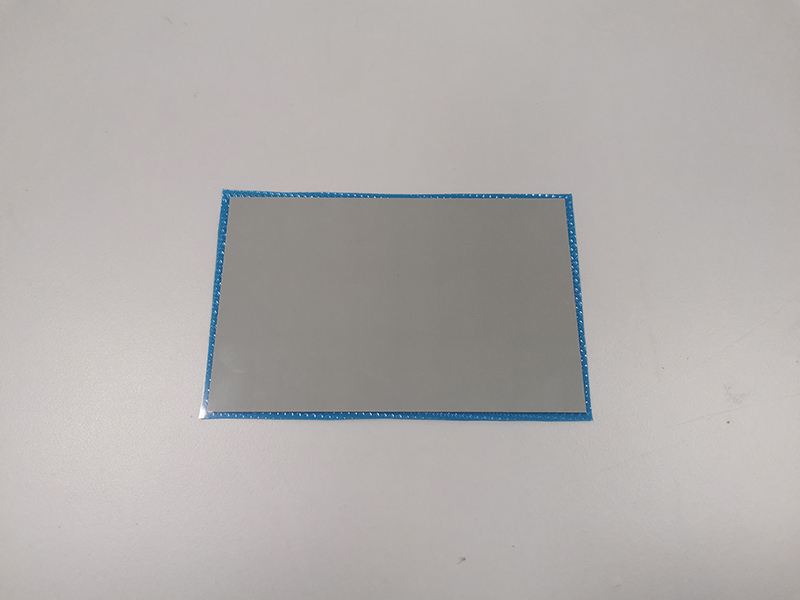

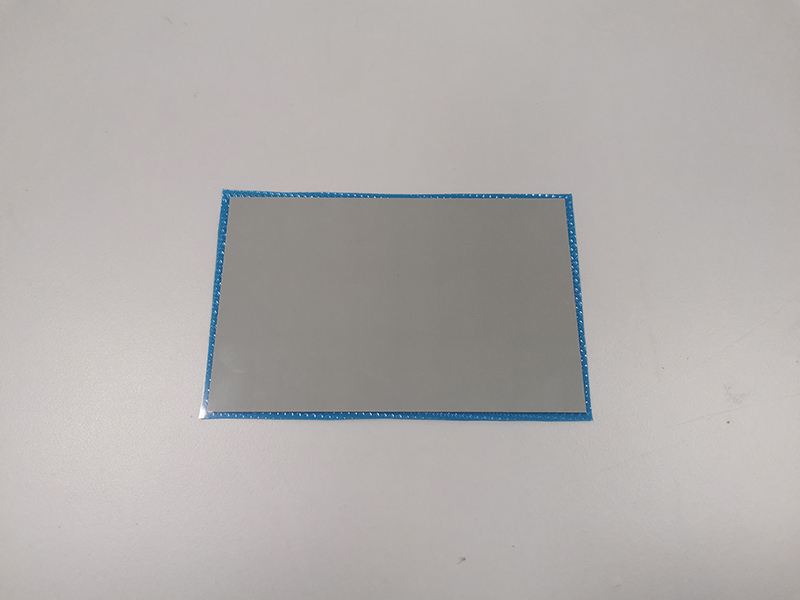

Thermal pads are commonly used in a wide variety of electronic devices, including computers, power supplies, automotive electronics, and LED lighting systems. Their primary function is to fill the thermal gap between heat-producing components, such as processors or power transistors, and heat dissipation structures like heat sinks. By improving thermal contact and enhancing heat transfer, thermal pads contribute to overall system stability, preventing overheating and prolonging the lifespan of the device.

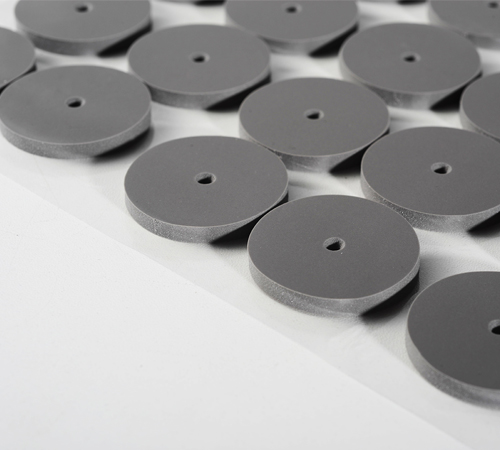

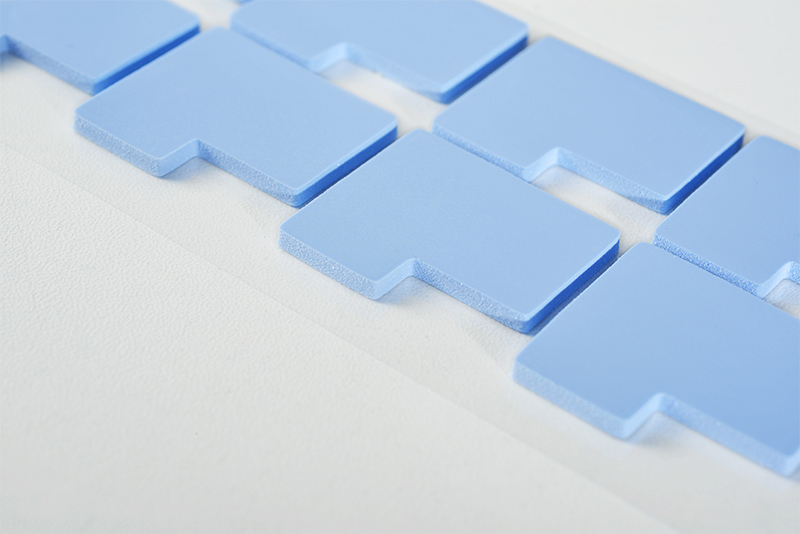

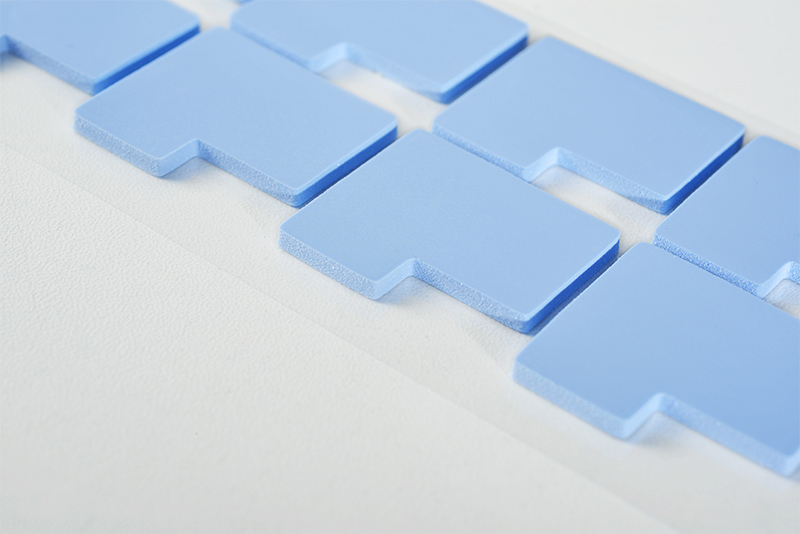

There are different types of thermal pads, with variations in composition and design. These differences affect not only the pad's thermal conductivity but also its ability to withstand high temperatures.

What Determines the Maximum Temperature of a Thermal Pad?

The maximum temperature tolerance of a thermal pad depends on several factors, each contributing to its performance under heat stress. These factors include:

1. Material Composition

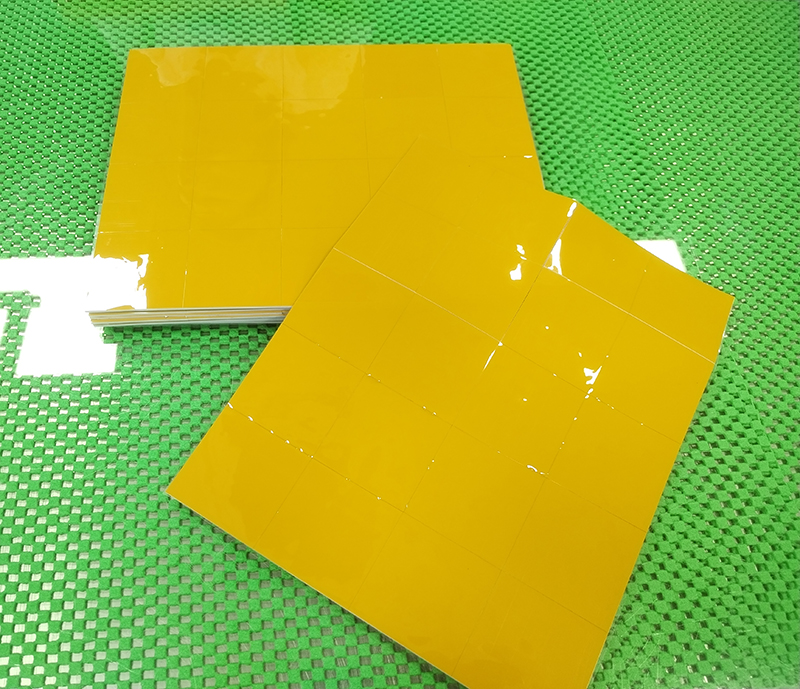

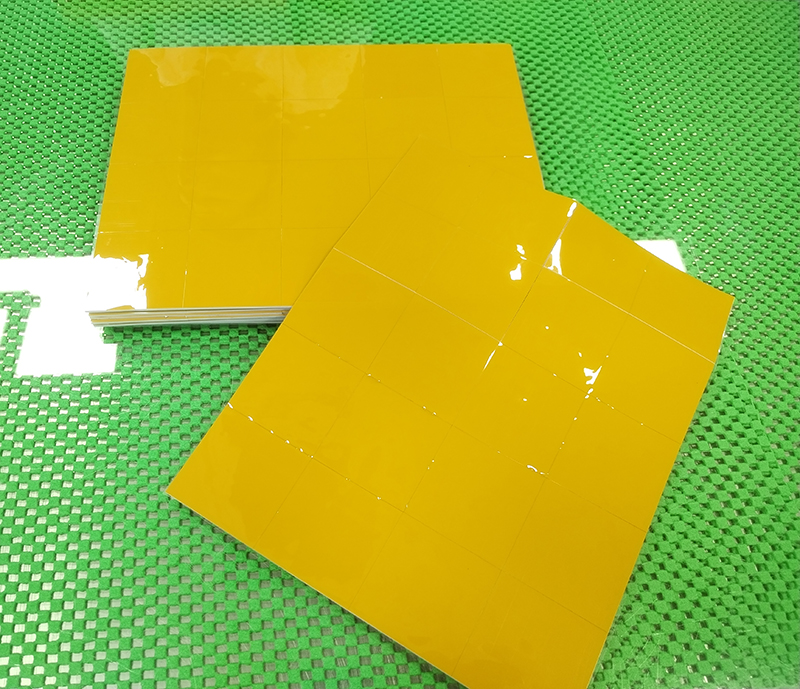

Thermal pads are made from various materials, including silicone, graphite, and polymer-based compounds. Each material has different thermal properties, including thermal conductivity and heat resistance. For example:

● Silicone-based thermal pads are commonly used due to their flexibility and ease of application. They typically have a maximum operating temperature range of 150°C to 200°C.

● Graphite thermal pads can withstand higher temperatures, often in the range of 250°C to 350°C, due to their excellent thermal conductivity and stability at high temperatures.

● Polymer-based pads may have lower temperature limits, generally around 120°C to 150°C, depending on the type of polymer used.

The materials chosen directly impact how well the thermal pad can resist heat and maintain its performance over time.

2. Pad Thickness

The thickness of the thermal pad also plays a role in its temperature tolerance. Thicker pads may be able to absorb more heat, but they also increase the thermal resistance, which could reduce the efficiency of heat dissipation. This becomes especially critical in high-temperature environments, where excessive thermal resistance can lead to overheating.

3. Environmental Factors

The operational environment in which the thermal pad is used will affect its maximum temperature. For example, in a sealed environment with limited airflow, such as within compact electronic devices, thermal pads may experience higher temperatures than in open systems with good ventilation. In these environments, the thermal pad may need to handle a broader range of temperatures while maintaining performance.

Typical Maximum Temperature Ranges for Different Thermal Pads

Understanding the maximum temperature range for various thermal pads is critical for selecting the right pad for a particular application. The following provides a general overview of typical maximum temperature tolerances:

● Low-Temperature Pads (Up to 100°C): These pads are suitable for applications where the temperature does not exceed 100°C, such as in basic consumer electronics.

● Medium-Temperature Pads (100°C to 150°C): Used in moderate applications like power electronics or general-purpose computing devices.

● High-Temperature Pads (150°C to 250°C): These thermal pads are typically found in high-performance electronics, including gaming PCs, high-powered computing equipment, and industrial machinery.

● Ultra-High-Temperature Pads (250°C to 350°C): Graphite and specialized metal-based thermal pads are used in environments where temperatures exceed 250°C, such as in LED lighting, automotive engines, and industrial power systems.

Selecting the appropriate thermal pad requires assessing the operational temperature range of the device and choosing a pad that offers sufficient heat resistance.

The Impact of Exceeding Maximum Temperature

When a thermal pad is exposed to temperatures beyond its maximum rating, several issues can arise, including:

● Degradation of Material Properties: Prolonged exposure to temperatures above the maximum tolerance can cause the material to degrade. Silicone, for example, may soften, lose elasticity, or become brittle over time, reducing its ability to maintain a secure and efficient thermal interface.

● Increased Thermal Resistance: As the pad material deteriorates, its thermal conductivity decreases, which leads to increased thermal resistance. This results in poor heat transfer and may cause critical components to overheat.

● Chemical Breakdown: In extreme cases, materials like silicone can undergo chemical breakdown, leading to the release of volatile compounds, which could damage sensitive electronic components.

Therefore, selecting a thermal pad with an appropriate temperature rating is essential to avoid the risks associated with overheating and material failure.

Conclusion: Maximizing the Efficiency and Longevity of Thermal Pads

Choosing the right thermal pad for an application involves a careful balance between its thermal conductivity, temperature tolerance, and overall durability. The maximum temperature for a thermal pad varies significantly based on material composition, pad thickness, and environmental factors, but selecting a pad with the appropriate temperature rating is key to ensuring effective heat management.

For most applications, silicone-based pads are sufficient, with a maximum temperature tolerance between 150°C and 200°C. However, for more extreme environments, such as automotive or industrial applications, high-performance graphite pads with a temperature tolerance of up to 350°C may be necessary.

Understanding the limitations of thermal pads and selecting the appropriate one based on operational conditions ensures both performance efficiency and the longevity of the device.

CN >

CN >