Solid State Drives (SSDs) are critical storage components in modern computer systems, and their performance and stability are significantly affected by temperature. To ensure efficient operation under high workloads, managing heat dissipation is a key concern in SSD design and application. This article explores the application locations of thermal gap pads on SSDs, analyzing their role in heat dissipation, selection criteria, and practical applications.

Overview of SSD Heat Dissipation Issues

With advancements in SSD technology, particularly in data transfer speeds and storage capacities, heat generation has increased. High-performance SSDs experience frequent read/write operations, leading to rapid temperature rises. Without effective thermal management, overheating can compromise SSD stability and shorten its lifespan. Choosing an appropriate cooling solution is essential, and thermal interface materials—especially thermal gap pads—offer an effective way to address this issue.

The Role of Thermal Gap Pads in SSDs

Thermal gap pads provide a heat conduction pathway, transferring heat from the SSD’s surface to heatsinks, enclosures, or other cooling components, keeping temperatures within a safe range. Unlike traditional metal-based thermal materials, thermal gap pads have excellent elasticity and compressibility, allowing them to conform tightly to SSD surfaces, even if they are uneven, ensuring efficient heat transfer.

Application Locations of Thermal Gap Pads on SSDs

Proper placement of thermal gap pads is crucial for effective heat dissipation. The key application areas include:

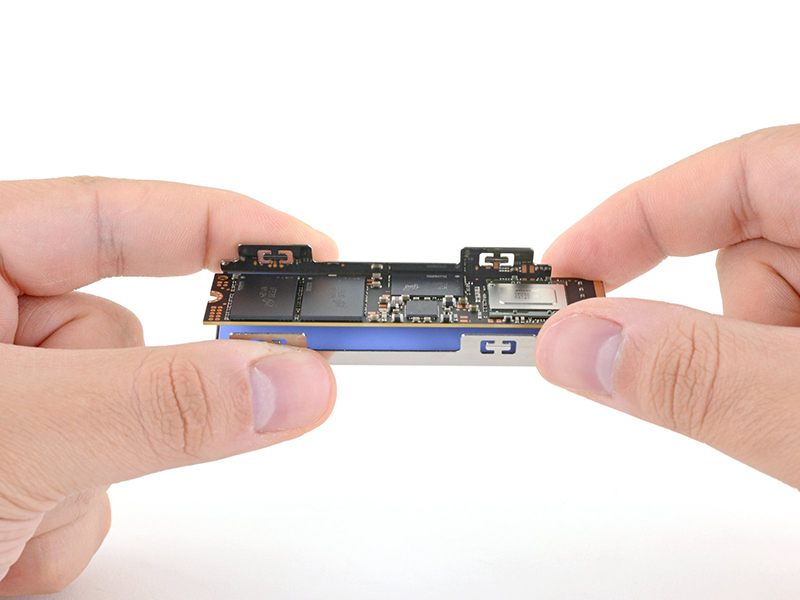

● Controller Chip Area: The SSD’s controller chip, often referred to as the "brain" of the SSD, is responsible for managing data read and write operations. It has high power consumption and generates significant heat. A thermal gap pad placed on the controller chip efficiently transfers heat away. In high-end M.2 NVMe SSDs, inadequate cooling can lead to thermal throttling, reducing performance.

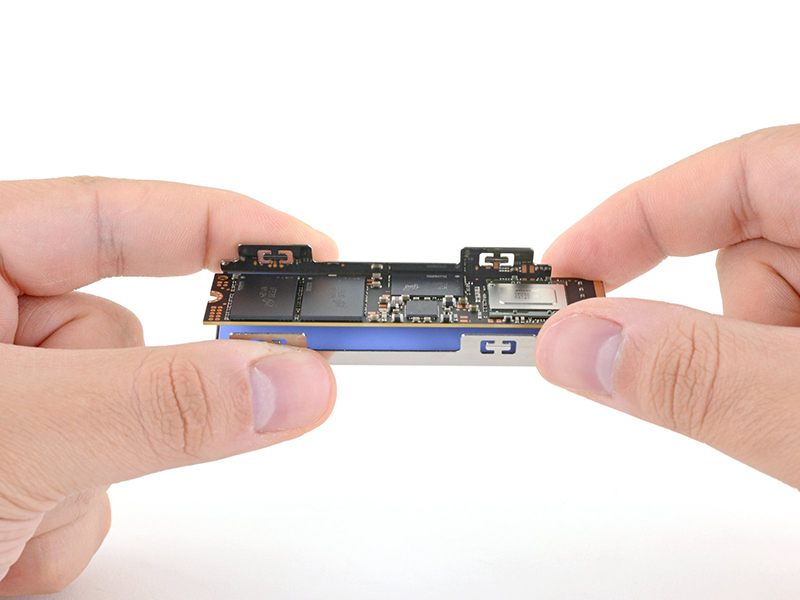

● NAND Flash Chip Area: NAND flash chips store data and generate heat during write and erase cycles. While individual chips produce moderate heat, multiple chips in high-capacity SSDs generate substantial cumulative heat. Applying a thermal gap pad over NAND flash chips helps dissipate this heat evenly. For instance, in 2.5-inch SATA SSDs, NAND chips are distributed on both sides of the PCB, requiring carefully cut pads for optimal coverage.

● Cache Chip Area (if present): Some high-performance SSDs include a dedicated cache chip to temporarily store data and accelerate operations. These chips generate heat under heavy workloads, making thermal management crucial. Applying a thermal gap pad to the cache chip ensures stable performance, especially in enterprise SSDs that handle continuous high data throughput.

● Backside of the PCB: Some SSD components on the PCB’s backside also generate heat. A thermal gap pad placed on these heat-generating components can help conduct heat to external cooling solutions, improving overall SSD thermal performance.

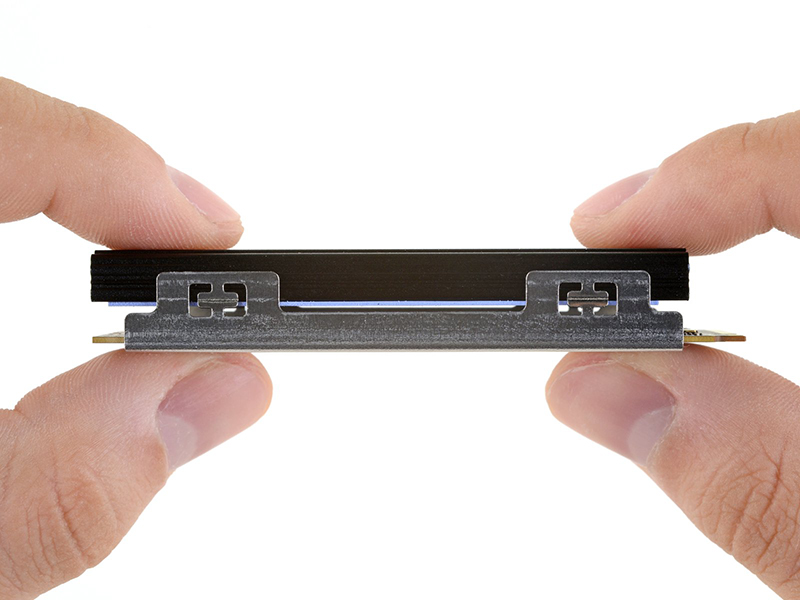

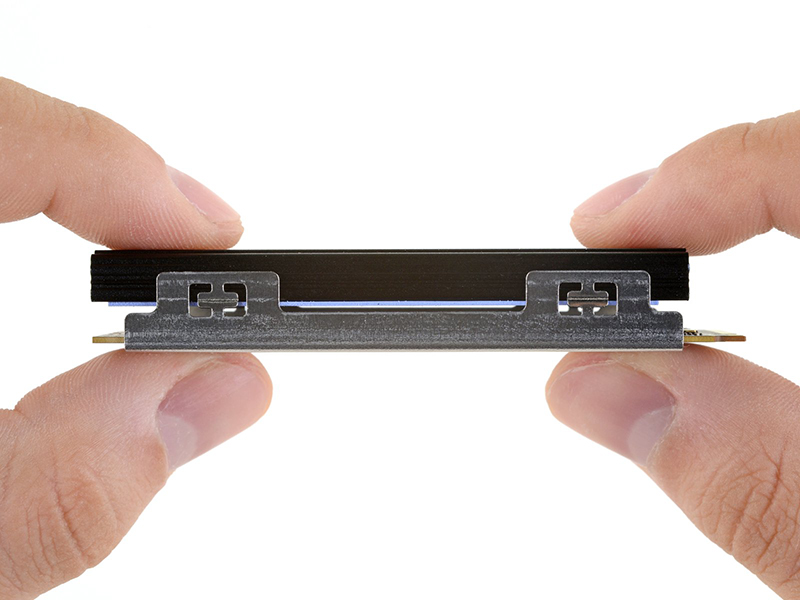

● Metal Enclosure Contact Areas: Many SSDs have metal enclosures that help dissipate heat. However, gaps between the SSD and the metal casing can hinder thermal transfer. Using thermal gap pads to fill these gaps ensures efficient heat conduction.

Selection Criteria for Thermal Gap Pads

To ensure effective SSD cooling, consider the following factors when selecting thermal gap pads:

● Thermal Conductivity: A key factor determining efficiency. Higher thermal conductivity (above 2 W/m·K) ensures rapid heat transfer.

● Thickness and Compressibility: The pad should be thick enough to fill gaps but not hinder heat conduction. It must also be compressible for optimal surface contact.

● High-Temperature Resistance: SSDs can reach high temperatures during operation, requiring thermal pads to withstand temperatures between -40°C to +200°C.

● Electrical Insulation: Good electrical insulation prevents short circuits and ensures component safety.

Steps and Precautions for Applying Thermal Gap Pads

1. Surface Cleaning: Remove dust and grease from the SSD and heatsink surfaces to ensure proper thermal conduction.

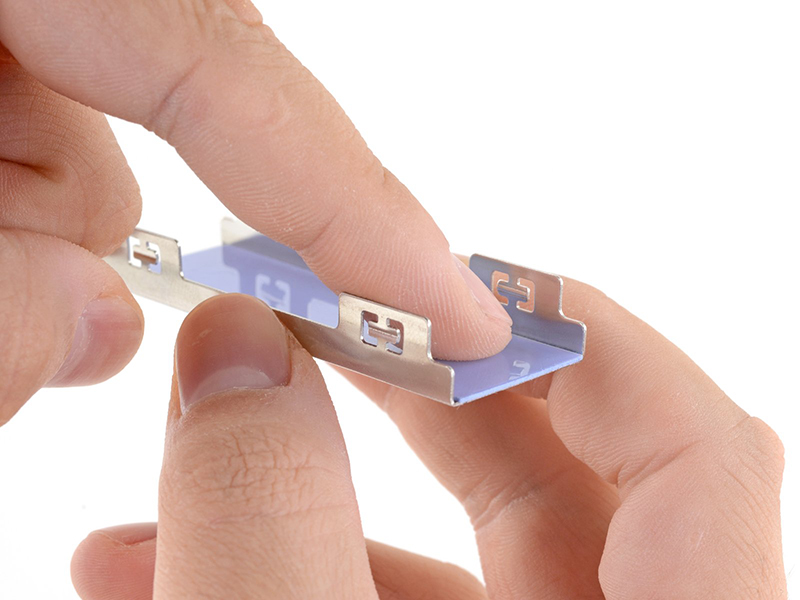

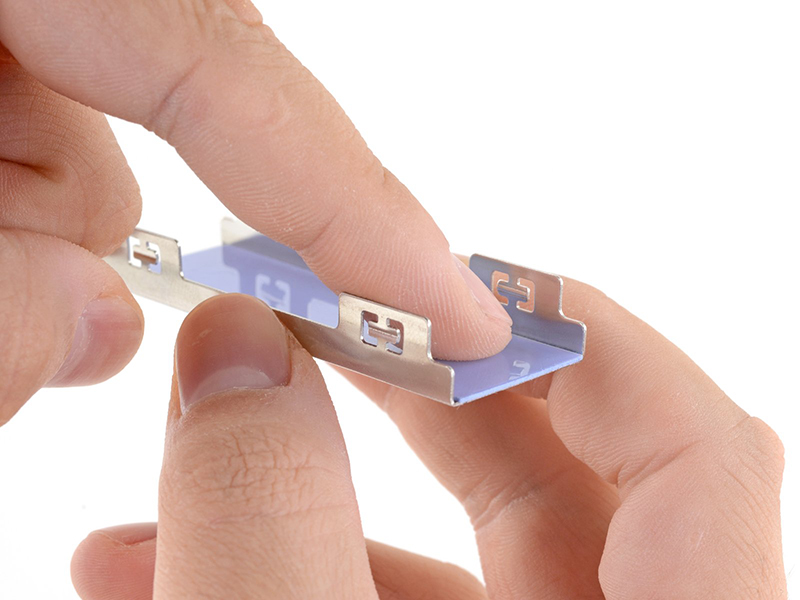

2. Measurement and Cutting: Cut the thermal pad to fit the SSD chip layout, ensuring full coverage without exceeding chip edges.

3. Even Application: Gently press the thermal pad onto the target area to eliminate air gaps or wrinkles.

4. Inspection and Fixation: Check for firm adhesion. If necessary, use clips or adhesive tape to secure the pad in place.

Conclusion

Effective thermal management is crucial for SSD stability and longevity, and thermal gap pads play a vital role in this process. By applying them to key areas such as the controller chip, NAND flash chips, cache chips, PCB backside, and metal enclosures, SSD operating temperatures can be reduced, preventing performance degradation and extending lifespan.

Choosing the right thermal gap pad involves considering thermal conductivity, thickness, compressibility, high-temperature resistance, and electrical insulation properties. Proper selection and installation enhance SSD cooling efficiency and reliability.

As SSD technology evolves, thermal gap pads will become increasingly essential in high-performance drives, serving as a core material for managing heat in power-intensive SSDs. Understanding their application and selection criteria will help users make informed decisions when purchasing and using SSDs, ensuring optimal long-term performance.

CN >

CN >