In modern electronics, Silicon Controlled Rectifiers (SCRs) are vital semiconductor devices widely used in power control, motor speed regulation, variable frequency drives, heater control, and many other applications. Due to their unique operating principles and control features, SCRs have become one of the key components in power electronics. NFION will delve into the definition, working principle, characteristics, and applications of SCRs, helping readers gain a comprehensive understanding of this important device.

What is a Silicon Controlled Rectifier (SCR)?

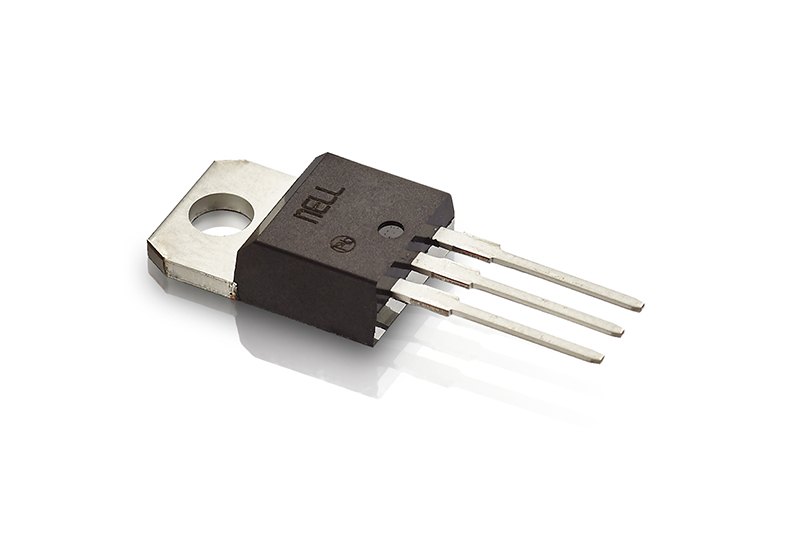

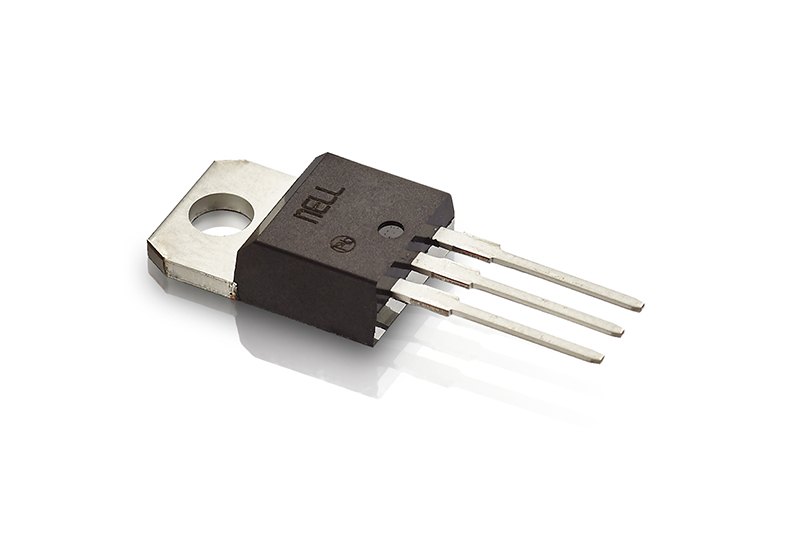

A Silicon Controlled Rectifier (SCR) is a semiconductor device composed of four layers of alternating P-type and N-type materials, forming a three-junction structure. It is a controlled rectifier, meaning it can adjust the current conduction based on a control signal, allowing precise current control. Unlike traditional diodes that conduct once and remain conductive, an SCR can be controlled to turn on and off using external trigger signals, making it highly versatile.

The basic structure of an SCR includes four layers of semiconductor materials arranged alternately as P-N-P-N, with three junctions formed between them. By applying a specific trigger signal, the SCR can switch to conduction, demonstrating high control over power flow. This makes SCRs useful in power switching, frequency modulation, and many other control applications.

How Does a Silicon Controlled Rectifier (SCR) Work?

The operation of an SCR can be explained by examining its structure and triggering method. The SCR consists of four layers of semiconductor material (PNPN structure), creating three P-N junctions. The operation process is as follows:

● Triggering Conduction: When a positive voltage is applied to the gate (G) and the current is sufficient, the internal P-N junctions undergo reverse breakdown, allowing current to flow through the main current path, putting the SCR into conduction. At this point, the SCR becomes conductive, and current can pass freely.

● Maintaining Conduction: Once the SCR enters conduction, it will remain in that state even if the gate signal is removed. It will continue conducting until the current through it reaches zero (or reverses direction), at which point it will stop conducting.

● Turning Off: To turn off the SCR, the current must reverse direction or fall to zero. Only when the current through the SCR reaches zero (or reverses) will it return to the non-conductive state.

This unique feature allows SCRs to function as both rectifiers and power controllers, offering high flexibility for applications such as speed regulation, dimming, and switching.

Characteristics of a Silicon Controlled Rectifier (SCR)

SCRs have several distinct features compared to other semiconductor devices, making them particularly suitable for power control applications. The key characteristics include:

● High Power Control: SCRs can withstand high voltages and currents, making them ideal for high-power electrical systems.

● Precise Control: The gate signal precisely controls the conduction and turn-off of the SCR, providing high accuracy in power control.

● Fast Response: SCRs transition quickly from off to on, enabling rapid switching.

● Durability and Reliability: SCRs can operate in harsh environments, including high temperatures and strong electromagnetic fields, offering long service life and high reliability.

These advantages make SCRs indispensable in many high-frequency, high-power electronic systems.

Applications of Silicon Controlled Rectifiers (SCRs)

SCRs are widely used in various fields due to their excellent power control capabilities. Below are some common applications:

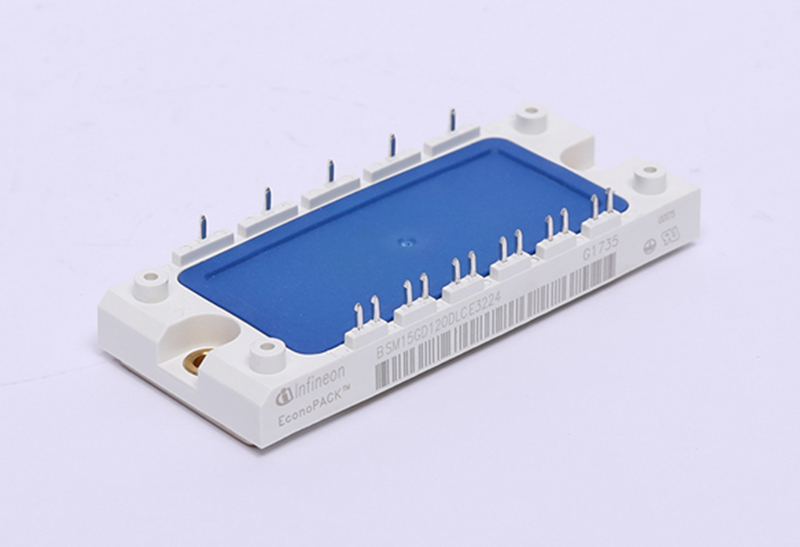

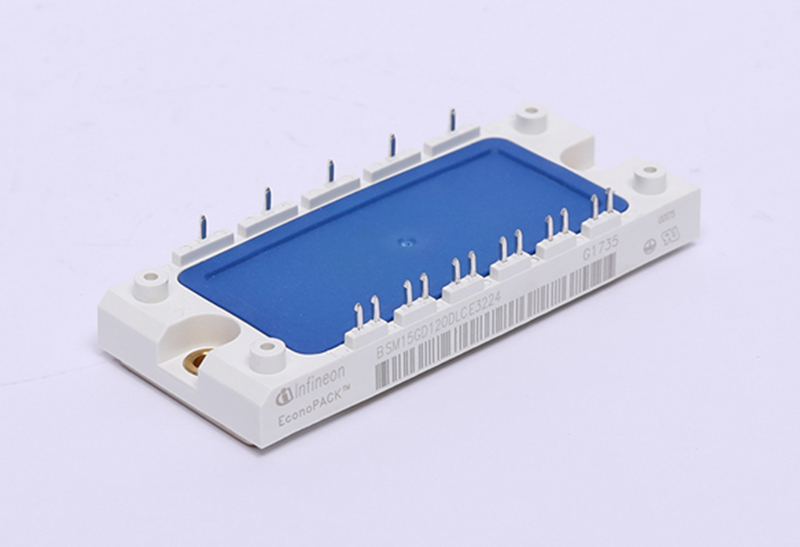

● Motor Speed Control: SCRs are used in motor control systems to adjust the timing of triggering, allowing variable motor speeds.

● Variable Frequency Drives (VFDs): SCRs regulate frequency in AC drives, adjusting voltage and frequency to optimize power usage.

● Power Transmission: SCRs play a crucial role in High Voltage Direct Current (HVDC) transmission systems by rectifying and inverting current, ensuring efficient power transfer.

● Heater Control: In industrial heating systems, SCRs regulate the current to control heating power, maintaining precise temperature control.

● Power Supply Regulation: SCRs are used in power regulators and stabilizers, maintaining consistent voltage and protecting equipment from voltage fluctuations.

Comparison Between SCRs and Other Semiconductor Devices

SCRs differ significantly from other common semiconductor devices such as diodes, TRIACs, and MOSFETs. The comparison table below highlights these differences:

|

Feature

|

SCR

|

Diode

|

TRIAC

|

MOSFET

|

|

Control Method

|

Triggered by gate signal

|

No control signal

|

Bidirectional control

|

Voltage-controlled

|

|

Conduction Hold

|

Maintains conduction without gate signal

|

Cannot stop once conducting

|

Bidirectional conduction

|

Requires maintained voltage

|

|

Application Range

|

High power, motor speed control

|

Low-power rectification

|

Small power AC-DC control

|

High-frequency, efficient switching

|

|

Response Speed

|

Moderate

|

Very fast

|

Moderate

|

Very fast

|

Conclusion

The Silicon Controlled Rectifier (SCR) is a crucial semiconductor device with unique current control capabilities. Its operation, characteristics, and applications in modern power electronics show its significant role in energy control systems, motor speed regulation, frequency modulation, and power switching. With the continuous development of power electronics technology, the use of SCRs will continue to expand, supporting the evolution of smart power systems and automation control technologies.

CN >

CN >