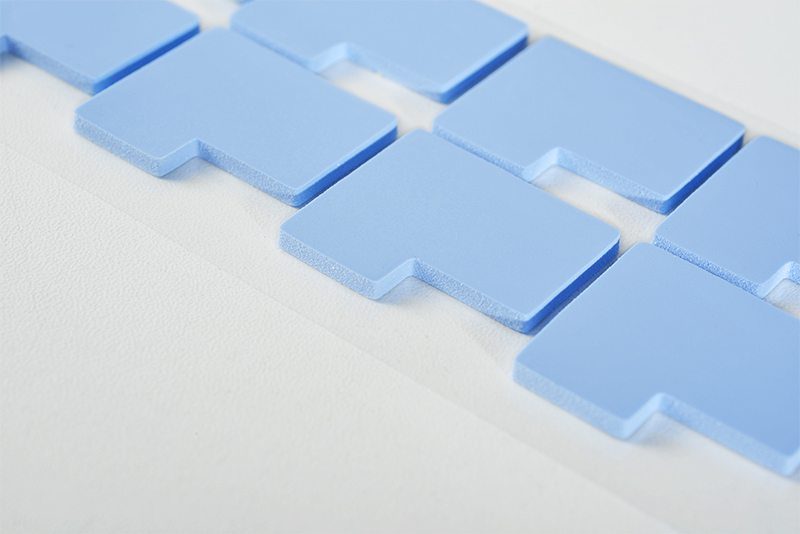

Thermal pads, also known as thermal interface pads or thermal cooling pads, are critical components in the management of heat dissipation in electronic devices. Their main function is to bridge the gap between heat-producing components (such as CPUs, GPUs, or power transistors) and heat sinks, thereby ensuring efficient thermal conduction. However, the effectiveness of a thermal pad heavily depends on its thickness. While the primary goal of using a thermal pad is to ensure good contact between surfaces for optimal heat transfer, excessive thickness can lead to a range of performance issues.

Impact on Thermal Performance

The primary role of a thermal pad is to conduct heat from the source (like a CPU) to a heat sink or other heat-dissipating components. When thermal pads are too thick, they can increase the thermal resistance between the component and the heat sink. This occurs because thicker pads may not allow for optimal contact between the surfaces, leading to the formation of an air gap or uneven pressure distribution. As a result, the efficiency of heat transfer is reduced, causing the component to operate at higher temperatures, which can lead to thermal throttling or even permanent damage.

Thermal Resistance and Thickness

Thermal resistance is a key factor in determining how well a material can transfer heat. The thicker the thermal pad, the higher its thermal resistance, which slows down the heat dissipation process. Even though the pad material itself may have high thermal conductivity, excessive thickness can significantly reduce overall thermal performance. Ideally, a thermal pad should be thick enough to fill the gap between components but not so thick that it impedes heat flow.

Pressure Distribution and Contact Quality

In electronic devices, particularly those with high-performance processors or other heat-generating components, uniform pressure across the thermal pad is crucial. When a thermal pad is too thick, the pressure exerted by the components on the pad may be insufficient to maintain good contact with the heat sink. This can result in poor heat transfer efficiency and uneven cooling, as the pad might not compress enough to form a consistent layer of thermal conduction.

Mechanical Deformation

Thicker thermal pads may not compress as effectively under pressure, especially if they are made of materials that do not exhibit significant elastic deformation. This can cause a reduction in the effectiveness of the thermal interface, as well as potential issues like thermal hotspots or localized overheating. Additionally, in devices where space is constrained, the excess thickness can result in mechanical misalignment, affecting overall device stability.

Potential Consequences of Using Thick Thermal Pads

Using thermal pads that are too thick can lead to a series of undesirable outcomes that directly affect both device performance and longevity:

● Overheating: Insufficient heat dissipation due to high thermal resistance can cause components to overheat. This can result in thermal throttling (automatic reduction in performance to avoid heat damage) or, in extreme cases, thermal shutdown to protect the device.

● Reduced Lifespan of Components: Continuous operation at higher temperatures can degrade the longevity of sensitive electronic components, such as processors, graphics chips, and other semiconductors. Overheating accelerates wear and tear, leading to a shorter device lifespan.

● System Instability: Thermal instability can cause systems to crash, freeze, or become unresponsive. This is especially critical in applications requiring high reliability, such as gaming, data centers, and industrial applications.

● Increased Power Consumption: As components struggle to dissipate heat effectively, they may consume more power in an attempt to cool down or maintain performance, leading to higher energy consumption.

How to Avoid Using Too Thick Thermal Pads

To avoid the issues associated with using thermal pads that are too thick, several considerations and best practices should be followed:

Choose the Right Thickness for the Gap

It is essential to match the thickness of the thermal pad with the specific gap between the component and the heat sink. Measure the gap carefully and choose a pad thickness that ensures good contact without excessive compression. Pads that are too thick may not compress sufficiently, while pads that are too thin may leave gaps, resulting in poor thermal conduction.

Consider the Compression Properties of the Material

Different materials used in thermal pads (such as silicone, graphite, or phase change materials) have different compressibility characteristics. Materials with better compression properties can be more forgiving in terms of thickness, as they can adapt to variations in surface roughness and component pressure. Selecting a material with appropriate compression and resilience can mitigate the negative impact of thicker pads.

Evaluate Manufacturer Guidelines

When selecting thermal pads for specific applications, it’s critical to follow manufacturer recommendations regarding pad thickness and compression specifications. Manufacturers often conduct extensive testing to determine the optimal thickness for various devices, taking into account thermal conductivity, pressure distribution, and space limitations.

Consider Alternative Thermal Management Solutions

In cases where a thicker pad is required due to specific design constraints, consider using additional thermal management techniques. This might include using advanced heat sinks, active cooling solutions, or thermal gels that can complement the thermal pad’s performance. These methods can help mitigate the effects of a thicker pad while still ensuring effective thermal management.

Conclusion

In summary, while thermal pads are essential for effective heat management in electronic devices, using a pad that is too thick can have significant negative consequences. These include reduced thermal performance, uneven pressure distribution, and potential overheating, which can impact system stability and the longevity of components. By carefully selecting the right pad thickness, considering material properties, and adhering to manufacturer guidelines, these issues can be avoided, ensuring optimal thermal performance and system reliability. Proper thermal management is crucial in today’s high-performance electronic systems, and understanding the role of thermal pad thickness is a vital step in achieving that goal.

CN >

CN >