Thermal conductive silicone pads are essential in heat dissipation applications for various electronic devices. Their performance depends significantly on proper storage conditions. With excellent thermal conductivity and high heat dissipation efficiency, thermal pads are widely used in electronics, LED lighting, communication devices, and computers. However, improper storage may compromise their physical properties, chemical stability, and lifespan. Nfion Thermal analyzes the storage environment requirements for thermal conductive silicone pads to help businesses and users understand how to store these materials effectively, ensuring optimal performance in real-world applications.

1. Temperature Control

- Temperature Range: The ideal storage temperature for thermal conductive silicone pads is between 15-25°C. Within this range, the material's molecular structure remains stable, avoiding oxidation at high temperatures or hardening at low temperatures.

- High-Temperature Risks: When storage temperatures exceed 25°C, especially over 30°C, the silicone resin's molecular chains may break or change structure, causing hardening and brittleness, which reduces thermal conductivity.

2. Humidity Control

- Humidity Range: It is recommended to maintain storage humidity between 30%-50%. High humidity may increase moisture absorption, leading to micro-accumulations of water molecules that reduce thermal filler uniformity and affect conductivity.

3. Light Control

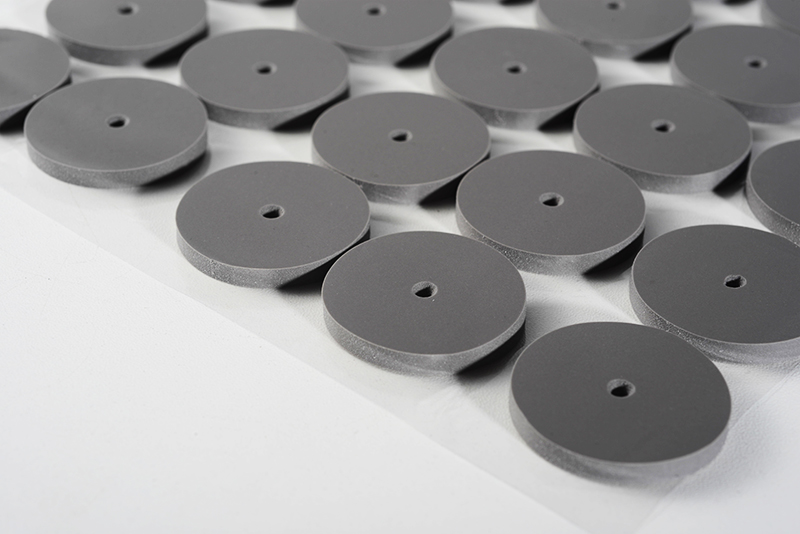

4. Air Circulation and Cleanliness

- Clean Environment: Thermal conductive silicone pads are sensitive to dust and particles. Small particles may affect the material's surface smoothness and thermal conductivity. Therefore, it’s essential to maintain clean air in the storage environment to avoid dust contamination.

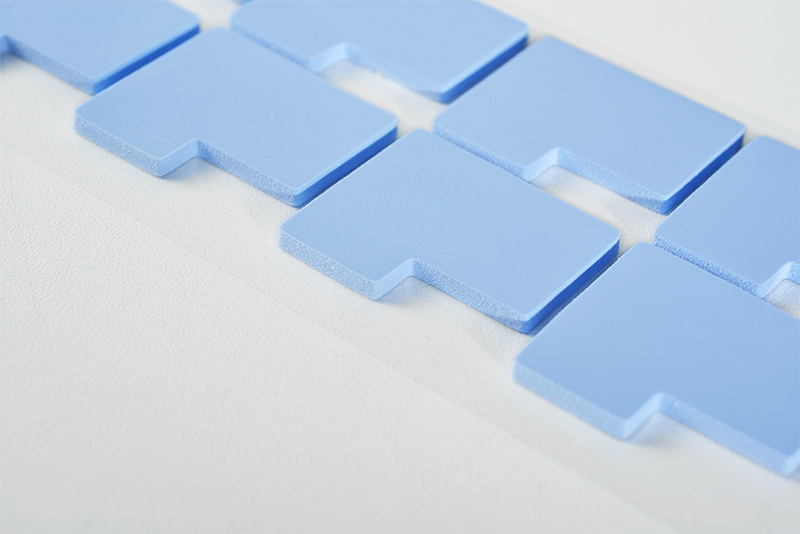

5. Physical Pressure and Protection Against Damage

- Avoid Compression: Thermal conductive silicone pads are soft, and prolonged compression may cause deformation, uneven thickness, and reduced thermal performance. Hence, storage should avoid stacking or pressing.

- Layered Protection: When storing in bulk, layered storage is recommended to prevent pads from compressing each other and to ensure each pad maintains its original shape without pressure.

1. Neglecting Temperature and Humidity Control: Some users believe that thermal silicone pads are environmentally adaptable and thus neglect temperature and humidity control. Long-term exposure to high temperatures and humidity, however, can accelerate material aging.

2. Exposure to Direct Sunlight: Some users overlook the effects of UV light on material aging, storing pads in locations with direct sunlight.

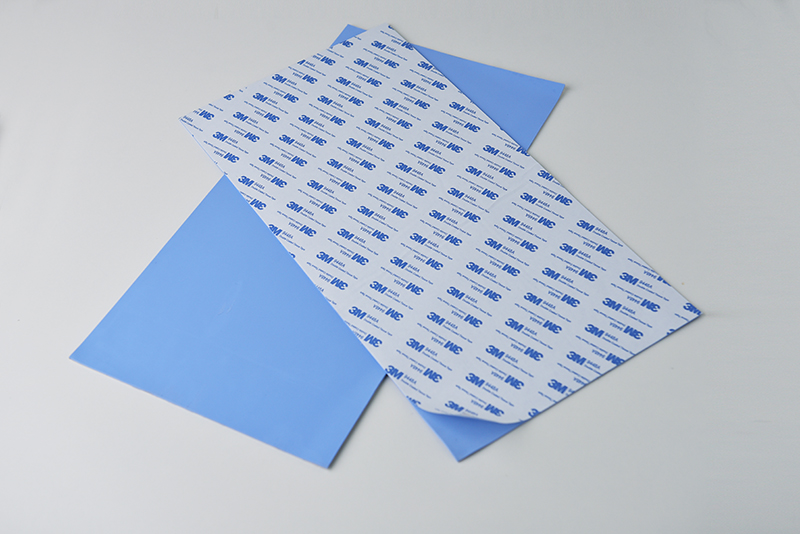

1. Sealed Packaging: Use sealed moisture-proof packaging bags to package each pad individually, preventing moisture and contamination.

2. Protection Measures: Place desiccants inside packaging boxes and check the desiccant status regularly to ensure moisture absorption.

3. Label Management: For pads stored long-term, mark the production date and recommended usage period on the packaging. Regular inspection of stock products is advised to ensure material quality.

CN >

CN >