With the rapid development of wireless charging technology, its application in smartphones, tablets, and other portable electronic devices is becoming increasingly widespread. However, wireless chargers generate significant heat during operation, which, if not effectively managed, can impact device performance, stability, and lifespan. Thermal silicone pads play a crucial role in heat management for wireless chargers. Nfion Thermal will delve into the characteristics, applications, and importance of thermal silicone pads in wireless charger heat management.

Basic Characteristics of Thermal Silicone Pads

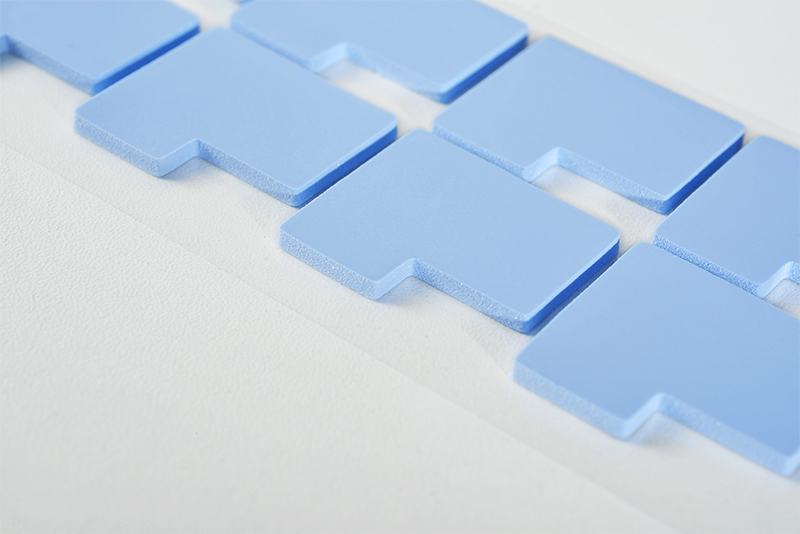

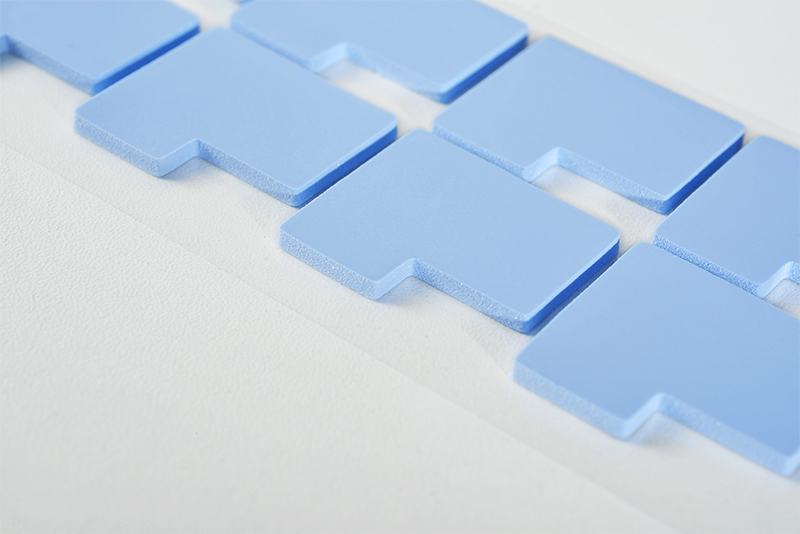

Thermal silicone pads are composed of silicone-based polymers and fillers, offering excellent thermal conductivity, flexibility, and electrical insulation. Key characteristics include:

1. High Thermal Conductivity: The thermal conductivity of thermal silicone pads typically ranges from 1.0to 12.0W/m·K, effectively conducting generated heat and reducing the risk of thermal accumulation.

2. Good Flexibility: The flexibility of silicone materials allows thermal silicone pads to adapt to components of various shapes and sizes, ensuring good contact and heat transfer.

3. Superior Electrical Insulation: While managing heat, thermal silicone pads provide effective electrical insulation, preventing short circuits and other electrical failures.

4. High-Temperature Resistance: Thermal silicone pads maintain stable performance in high-temperature environments, suitable for various operating conditions.

Challenges in Heat Management of Wireless Chargers

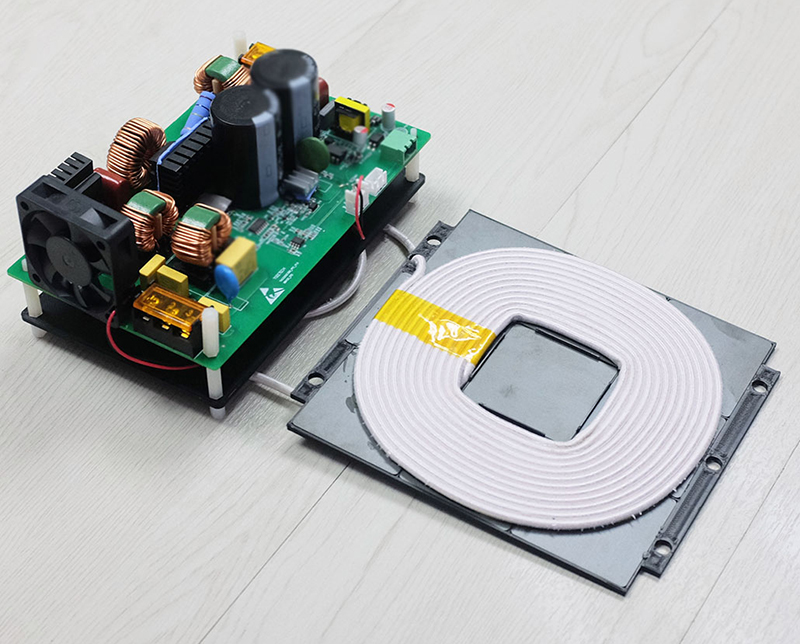

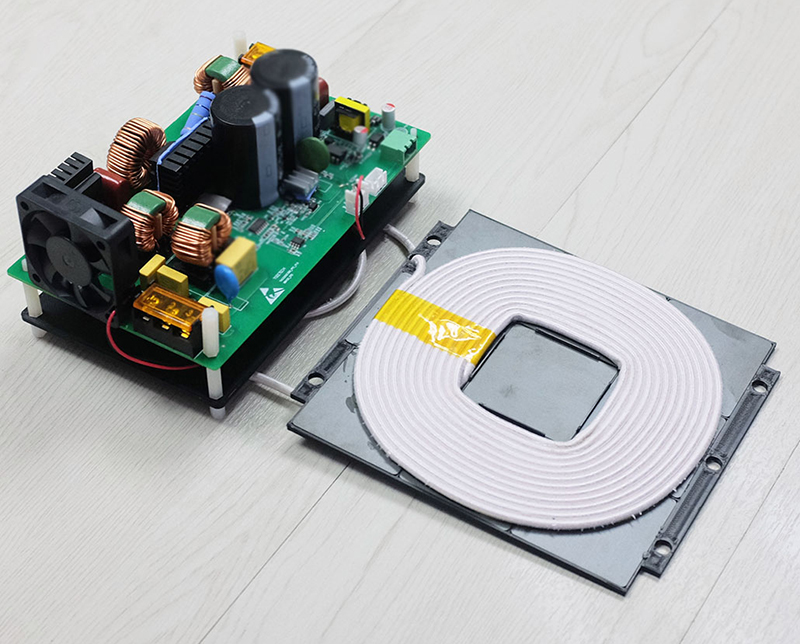

The working principle of wireless chargers involves transferring energy to the receiver through an electromagnetic field, involving several key components such as the transmitting coil, receiving coil, and power module. This process generates heat due to current flow and electromagnetic induction. Accumulated heat may lead to the following issues:

1. Performance Decline: High temperatures can affect the efficiency of electronic components, resulting in energy loss.

2. Device Stability Issues: Excessive temperatures can cause system instability, potentially leading to automatic shutdown or functional failures.

3. Reduced Lifespan: Prolonged high-temperature environments accelerate the aging of electronic components, reducing the overall lifespan of the product.

Applications of Thermal Silicone Pads in Heat Management

1. Use as Thermal Interface Materials

Thermal silicone pads are often used as thermal interface materials (TIMs) to fill gaps between the transmitting coil and heatsink, optimizing the heat conduction path. By ensuring good contact, thermal silicone pads significantly improve thermal conductivity efficiency, effectively lowering component temperatures.

2. Design of Heat Dissipation Structures

In the design of wireless chargers, a reasonable heat dissipation structure is crucial. Thermal silicone pads not only serve as thermal conduction mediums but can also be combined with heatsinks to diffuse heat, achieving a more uniform temperature distribution. This combination design can effectively reduce hotspots and enhance the overall heat management capability of the device.

3. Integration of Electrical Insulation Function

The electrical insulation properties of thermal silicone pads provide additional safety in heat management. In some high-power wireless chargers, thermal silicone pads not only perform heat conduction but also prevent current leakage, ensuring safe operation of the device.

Conclusion

The application of thermal silicone pads in wireless charger heat management is of great significance. Through their excellent thermal conductivity, flexibility, and electrical insulation, thermal silicone pads effectively address the heat management challenges faced by wireless chargers in high-temperature environments. In the future, with the continuous advancement of wireless charging technology, the demand for thermal materials will keep growing. Therefore, developing higher-performance thermal silicone pads will be key to enhancing the performance and reliability of wireless chargers.

CN >

CN >