Is Higher Breakdown Voltage Always Better for Single-Component Thermal Gels?

Single-component thermally conductive gels are crucial materials for thermal management in electronic devices, primarily used to efficiently transfer heat from electronic components to heat sinks or other cooling media. As dielectric materials, these gels play a vital role in both electrical insulation and thermal conduction. Breakdown voltage is a key metric for evaluating their electrical insulation properties. While higher breakdown voltage typically indicates better insulation under high voltage, whether higher is always better requires a more nuanced discussion.

Importance of Breakdown Voltage

Breakdown voltage refers to the minimum voltage at which a material experiences electrical breakdown under an applied electric field. For thermally conductive gels, high breakdown voltage usually signifies excellent electrical insulation, preventing current from passing through the material and causing short circuits or equipment damage. In many applications, such as high-power appliances, transformers, and power electronics, thermally conductive gels are required to have high breakdown voltage to ensure safety and stability under high-voltage conditions.

Balancing Breakdown Voltage and Thermal Conductivity

Although high breakdown voltage is crucial for electrical insulation, it is not always better in practice. The primary function of a thermally conductive gel is to conduct heat, and there may be a trade-off between breakdown voltage and thermal conductivity. Typically, the thermal conductivity of a material is closely related to its filler content. High thermal conductivity fillers (e.g., boron nitride, alumina) can significantly enhance the material's thermal conductivity but may reduce its electrical insulation, thereby lowering the breakdown voltage. Therefore, in designing single-component thermally conductive gels, a balance must be struck between thermal conductivity and electrical insulation.

Moreover, different applications have varying requirements for the breakdown voltage of thermally conductive gels. For example, in low-voltage scenarios like LED lighting and smartphone cooling, the breakdown voltage does not need to be very high, with more focus placed on thermal conductivity and ease of application. In contrast, high-voltage equipment, such as electric vehicle batteries and industrial inverters, requires high breakdown voltage to ensure electrical safety. Thus, the specific breakdown voltage requirements should be determined based on the application rather than simply pursuing higher values.

Material Design and Future Prospects

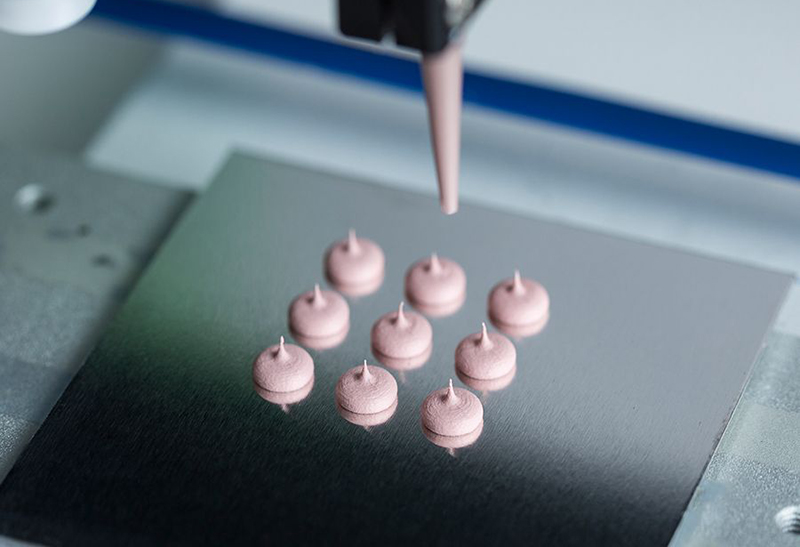

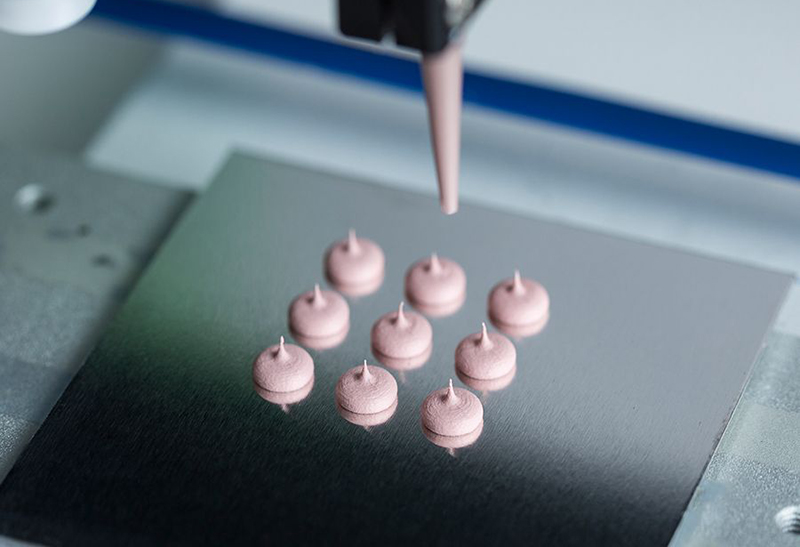

In designing single-component thermally conductive gels, material scientists often employ various techniques to optimize both breakdown voltage and thermal conductivity. For example, choosing the appropriate filler type and size, improving filler-matrix interface compatibility, and optimizing the material's crosslinking structure can enhance both breakdown voltage and thermal conductivity. Additionally, the introduction of novel nanomaterials and modification techniques offers promising avenues for improving the overall performance of thermally conductive gels.

As electronic devices increasingly demand high-performance thermal materials, future research on single-component thermally conductive gels will likely focus on multifunctionality, not only balancing breakdown voltage and thermal conductivity but also addressing requirements for environmental friendliness, longevity, and ease of application. Such multifunctional, high-performance gels will have broad applications in thermal management and electrical insulation of electronic components.

Conclusion

In summary, higher breakdown voltage in single-component thermally conductive gels is not always better but should be optimized based on specific application requirements. While improving breakdown voltage is essential for enhancing electrical insulation, it should not come at the expense of thermal conductivity. Future research on thermally conductive gels should emphasize balancing multiple performance metrics to meet diverse application needs. Only by achieving the optimal balance between breakdown voltage and thermal conductivity can more competitive, high-performance thermal materials be developed.

CN >

CN >