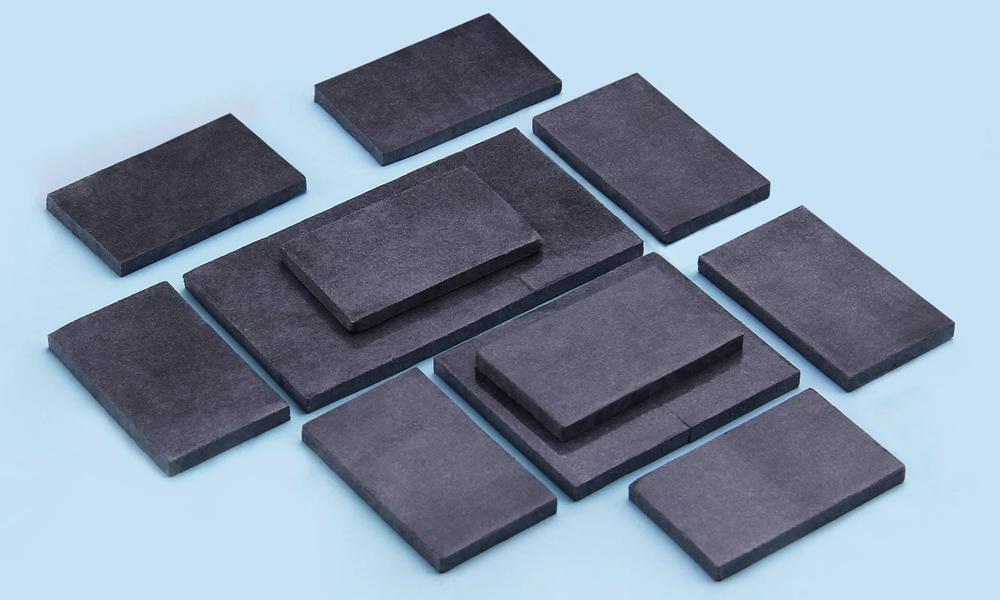

As electronic devices continue to evolve towards being lighter and more high-performing, heat dissipation has become an essential technical challenge. Carbon fiber thermal pads, as a new type of thermal management material, play a significant role in improving the heat dissipation efficiency of electronic products.

Overview of Carbon Fiber Thermal Pads

Definition:

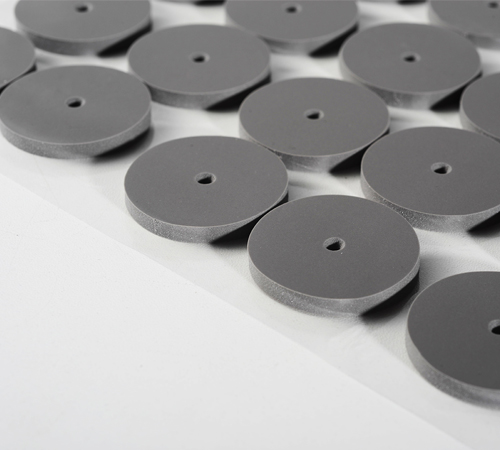

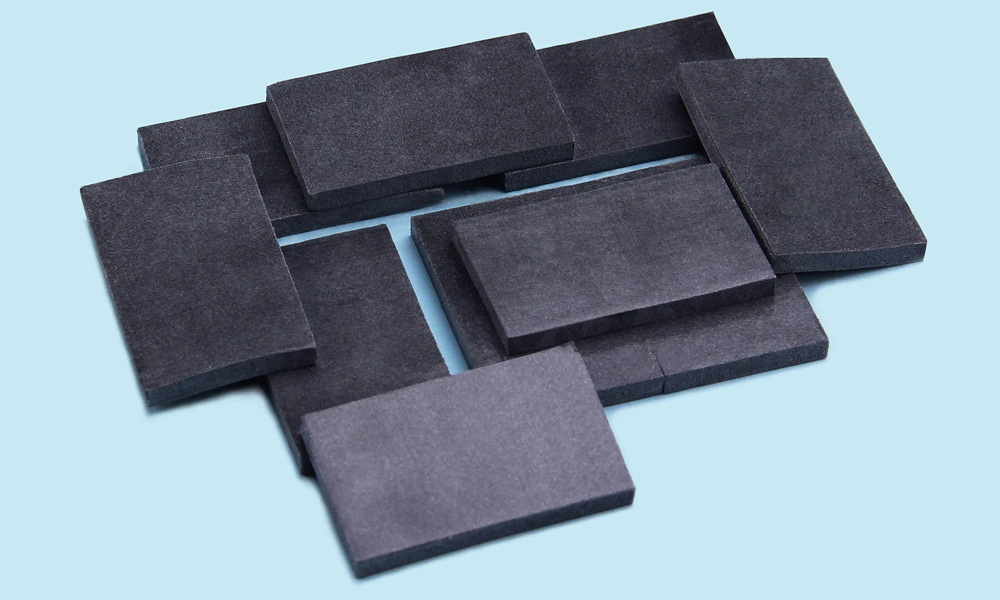

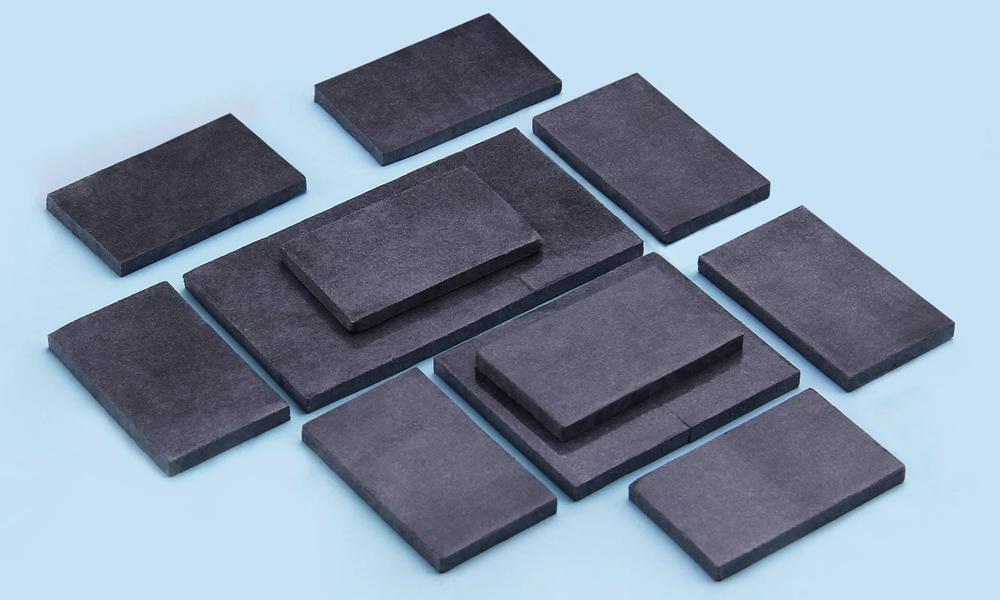

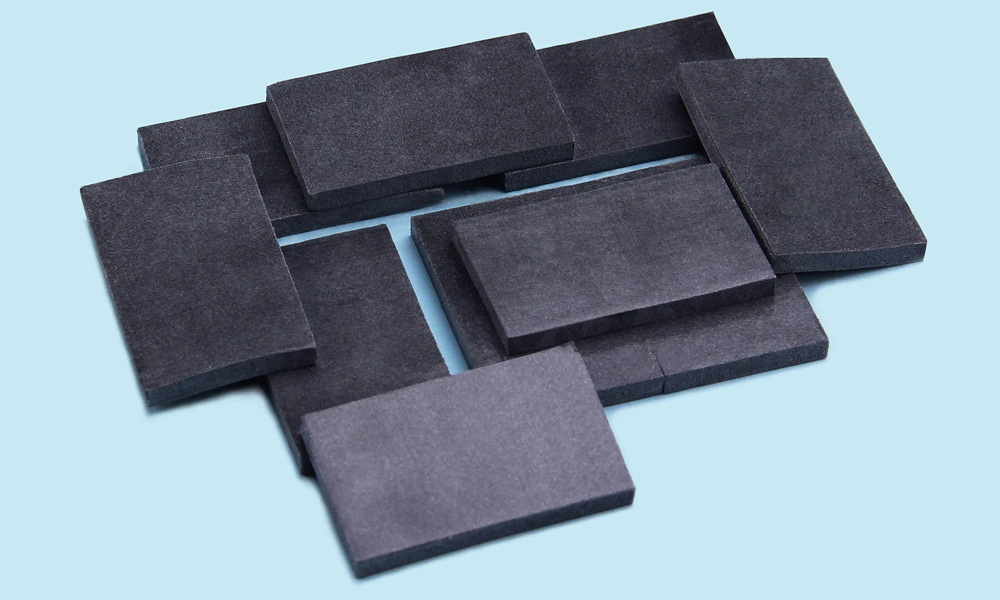

A carbon fiber thermal pad is a thermal conductive component made from a composite material with carbon fiber as the main ingredient. It combines the excellent mechanical properties of carbon fiber with good thermal conductivity, providing a key role in heat conduction in electronic devices.

Composition:

Carbon fiber thermal pads are usually composed of high-purity carbon fibers combined with a polymer matrix. Carbon fibers have extremely high strength and rigidity, good thermal conductivity, and a low thermal expansion coefficient, while the polymer matrix provides the flexibility and processability required for the pad.

Characteristics of Carbon Fiber Thermal Pads

1. High Thermal Conductivity: Carbon fibers themselves have good thermal conductivity. Combined with high thermal conductive fillers, carbon fiber thermal pads can quickly and effectively transfer heat, reducing the operating temperature of electronic components.

2. Lightweight and Strong: The low density and high strength of carbon fibers allow the thermal pad to be lightweight while maintaining good mechanical strength and durability, making it suitable for various complex environments.

3. Good Flexibility: Carbon fiber thermal pads have a certain degree of flexibility, allowing them to adapt well to irregular surfaces, increasing the contact area at the thermal interface and thus enhancing thermal efficiency.

4. High Temperature Resistance: Carbon fiber thermal pads can maintain stable physical and chemical properties at high temperatures, making them resistant to decomposition or aging, and suitable for high-temperature environments.

5. Low Thermal Expansion Coefficient: Carbon fiber thermal pads have a low thermal expansion coefficient, meaning they undergo minimal dimensional changes with temperature fluctuations, reducing stress problems caused by thermal expansion and contraction.

Manufacturing Process of Carbon Fiber Thermal Pads

The manufacturing process of carbon fiber thermal pads mainly includes the following steps:

1. Material Preparation: Select high-quality carbon fibers and thermal conductive fillers to ensure their purity and performance.

2. Fiber Weaving: Weave the carbon fibers into fabrics according to predetermined methods, ensuring good structural strength and thermal performance.

3. Filler Mixing: Distribute the thermal conductive fillers evenly in the carbon fiber fabric using an appropriate mixing process to enhance the thermal effect.

4. Molding and Processing: Form the mixed materials into the desired shape using molds, applying appropriate temperature and pressure to solidify the shape into the required thermal pad form.

5. Post-Processing: Perform necessary post-processing on the molded thermal pads, such as cutting and surface treatment, to ensure smooth surfaces and precise dimensions.

Applications of Carbon Fiber Thermal Pads

1. Electronic Device Heat Dissipation: Widely used in heat management of electronic devices like computers, smartphones, and tablets, carbon fiber thermal pads can effectively reduce the internal temperature of devices, extending their lifespan.

2. LED Lighting: In LED lighting equipment, carbon fiber thermal pads can improve heat dissipation efficiency, reduce light decay, and enhance the lifespan and stability of light sources.

3. Electric Vehicles: Carbon fiber thermal pads have important applications in the battery and electronic control systems of electric vehicles, improving system reliability and safety.

4. Communication Equipment: In high power density devices like communication base stations and servers, carbon fiber thermal pads help improve heat dissipation, ensuring the normal operation of the equipment.

Conclusion

With their high thermal conductivity, lightweight and strong characteristics, good flexibility, high temperature resistance, and low thermal expansion coefficient, carbon fiber thermal pads have become an important material in the field of electronic heat dissipation. Their broad application prospects and continuously developing manufacturing processes will enable them to play an increasingly important role in future electronic device heat management. By thoroughly understanding the material composition, characteristics, manufacturing processes, and applications of carbon fiber thermal pads, we can better leverage their advantages to provide efficient and reliable heat dissipation solutions for electronic devices.

CN >

CN >